Preparing technology for cinnamon essential oil

A cinnamon essential oil and preparation technology, which is applied in the directions of essential oils/spices, fat production, etc., can solve the problems of high energy consumption, waste of resources, low extraction efficiency, etc., achieve simple process methods, improve production efficiency, and accelerate the distillation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

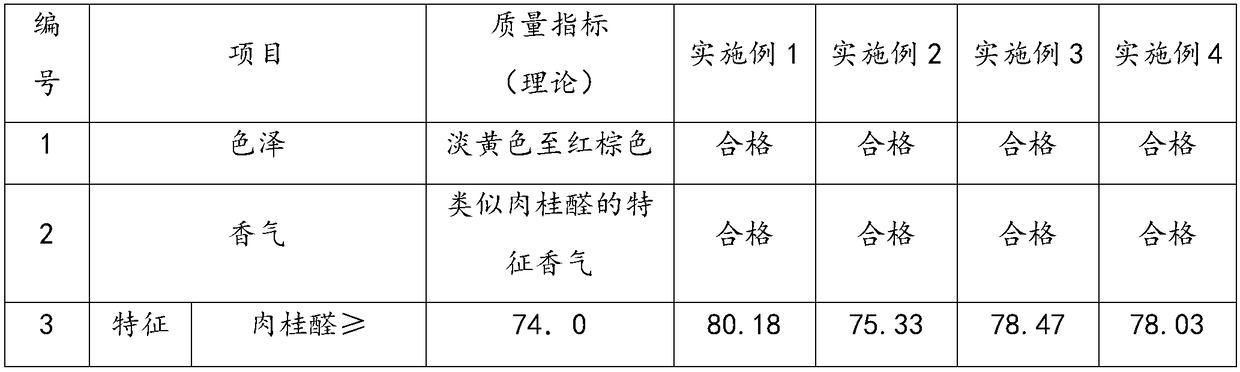

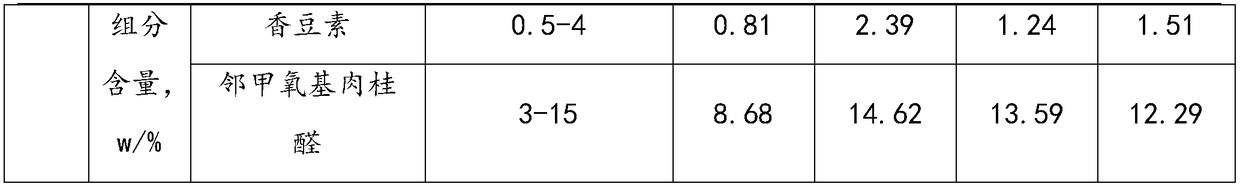

Examples

Embodiment 1

[0028] A preparation process of cinnamon essential oil, comprising the following steps:

[0029] Step 1: Take more than 500g of dried cassia twigs, remove the impurities in the cinnamon twigs, take 500g of cassia twigs, grind them with a coarse powder machine, and sieve them with a No. 3 sieve (355 μm) to obtain cassia bark, cassia bark twig or bay leaf powder;

[0030] Step 2: adding an appropriate amount of water to the cassia twig powder, the mass ratio of water to raw materials is 5:1, stirring evenly to obtain a mixed material;

[0031] Step 3: Add composite microorganisms to the mixed material. The dry weight of the composite microorganisms is 0.03% of the raw material, that is, 0.15g. Among them, the composite microorganisms include Rhodococcus: 0.0214g, Lactobacillus: 0.0429g, Saccharomyces: 0.0214g, Nocardia Bacteria: 0.0429g and Aspergillus: 0.0214g, carry out micro-fermentation in a bioreactor, control the temperature at 25°C, and ferment for 4 hours to obtain a fe...

Embodiment 2

[0036] A preparation process of cinnamon essential oil, comprising the following steps:

[0037] Step 1: Weigh more than 500g of dried cinnamon, remove the sundries in the cinnamon, take 500g of cinnamon, pulverize it with a coarse powder machine, and sieve it with a No. 3 sieve to obtain cinnamon, cinnamon sticks or cinnamon leaf powder;

[0038] Step 2: adding an appropriate amount of water to the cinnamon powder, the mass ratio of water to raw materials is 12:1, stirring evenly to obtain a mixed material;

[0039] Step 3: Add compound microorganisms to the mixed material, the dry weight of the compound microorganisms is 0.02% of the raw material, that is, 0.1g, wherein the compound microorganisms include Rhodococcus: 0.02g, Lactic acid bacteria: 0.02g, Saccharomyces: 0.02g, Nocardia : 0.02g and Aspergillus: 0.02g, carry out micro-fermentation in a bioreactor, control the temperature at 32°C, and ferment for 2 hours to obtain a fermented liquid;

[0040] Step 4: adding comp...

Embodiment 3

[0044] A preparation process of cinnamon essential oil, comprising the following steps:

[0045] Step 1: Weigh more than 500g of dried osmanthus leaves, remove the sundries in the osmanthus leaves, take 500g of osmanthus leaves, grind them with a coarse powder machine, and sieve them with a No. 3 sieve to obtain cinnamon bark, cinnamon sticks or osmanthus leaf powder;

[0046] Step 2: adding an appropriate amount of water to the bay leaf powder, the mass ratio of water to raw materials is 20:1, stirring evenly to obtain a mixed material;

[0047]Step 3: Add compound microorganisms to the mixed material. The dry weight of the compound microorganisms is 0.01% of the raw material, that is, 0.05g. Among them, the compound microorganisms include Rhodococcus: 0.0125g, Lactobacillus: 0.00625g, Saccharomyces: 0.0125g, Nocardia Bacteria: 0.00625g and Aspergillus: 0.0125g, carry out micro-fermentation in a bioreactor, control the temperature at 40°C, and ferment for 0.5h to obtain a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com