A kind of wear-resisting, acid-resistant and non-toxic artificial graft film preparation method

An implant and artificial technology, applied in the direction of coating, metal material coating process, prosthesis, etc., can solve the problem of "three-body" wear and other problems, achieve the effect of reducing thermal stress, improving stability, and inhibiting interface corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

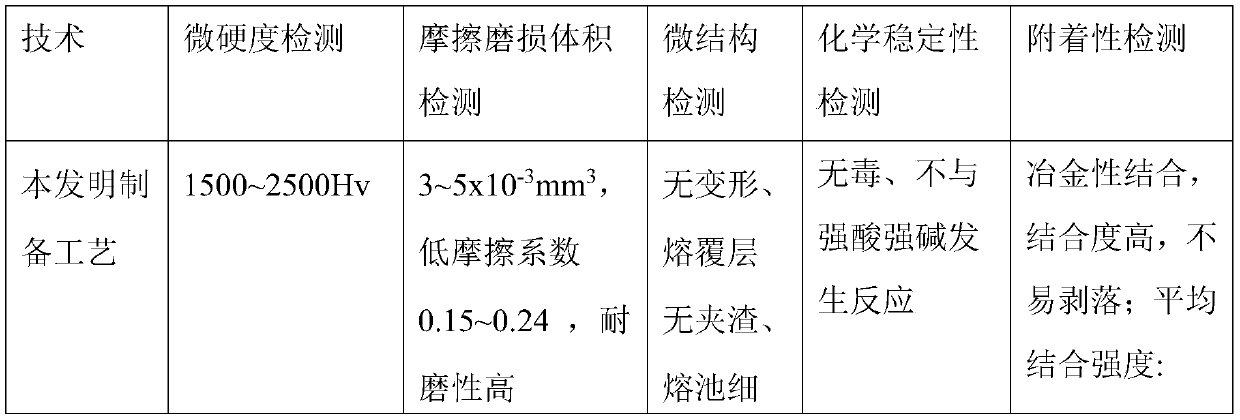

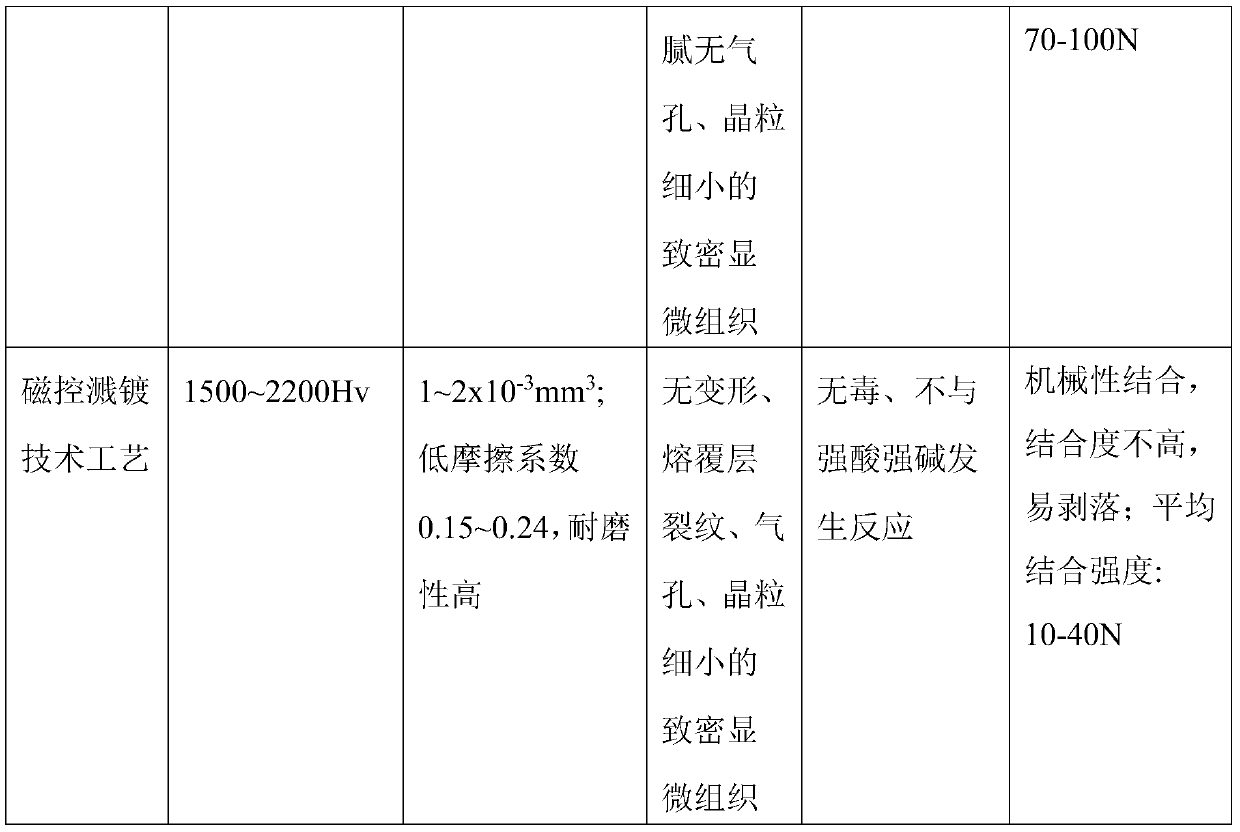

[0018] Embodiment 1, a method for preparing a wear-resistant, acid-resistant and non-toxic artificial graft film layer, the film layer includes a bonding layer, a transition layer and a surface layer sequentially arranged on the surface of the friction partner of the artificial graft from the inside to the outside, The bonding layer is a nickel-titanium layer, the transition layer is a titanium-doped diamond-like layer with zirconium elements, and the surface layer is a zirconium-doped diamond-like layer;

[0019] The preparation method comprises the following steps:

[0020] 1) Forming of the adhesive layer: using the metal-metal artificial implant as the substrate, the nickel target and the titanium target are sputter-deposited on the surface of the artificial implant friction partner by magnetron sputtering to form an adhesive bond. Layer coating, and then use laser cladding method to melt the above-mentioned adhesive layer coating, so as to form the adhesive layer;

[002...

Embodiment 2

[0028] Embodiment 2, a method for preparing a wear-resistant, acid-resistant and non-toxic artificial graft film layer, the film layer includes a bonding layer, a transition layer and a surface layer sequentially arranged on the surface of the friction partner of the artificial graft from the inside to the outside, The bonding layer is a nickel-titanium layer, the transition layer is a titanium-doped diamond-like layer with zirconium elements, and the surface layer is a zirconium-doped diamond-like layer;

[0029] The preparation method comprises the following steps:

[0030] 1) Forming of the adhesive layer: using the metal-metal artificial implant as the substrate, the nickel target and the titanium target are sputter-deposited on the surface of the artificial implant friction partner by magnetron sputtering to form an adhesive bond. Layer coating, and then use laser cladding method to melt the above-mentioned adhesive layer coating, so as to form the adhesive layer;

[003...

Embodiment 3

[0038] Embodiment 3, a method for preparing a wear-resistant, acid-resistant and non-toxic artificial graft film layer, the film layer includes a bonding layer, a transition layer and a surface layer sequentially arranged on the surface of the friction partner of the artificial graft from the inside to the outside, The bonding layer is a nickel-titanium layer, the transition layer is a titanium-doped diamond-like layer with zirconium elements, and the surface layer is a zirconium-doped diamond-like layer;

[0039] The preparation method comprises the following steps:

[0040] 1) Forming of the adhesive layer: using the metal-metal artificial implant as the substrate, the nickel target and the titanium target are sputter-deposited on the surface of the artificial implant friction partner by magnetron sputtering to form an adhesive bond. Layer coating, and then use laser cladding method to melt the above-mentioned adhesive layer coating, so as to form the adhesive layer;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com