Special fertilizer for long-acting sustained release of potatoes and preparation method and application of special fertilizer

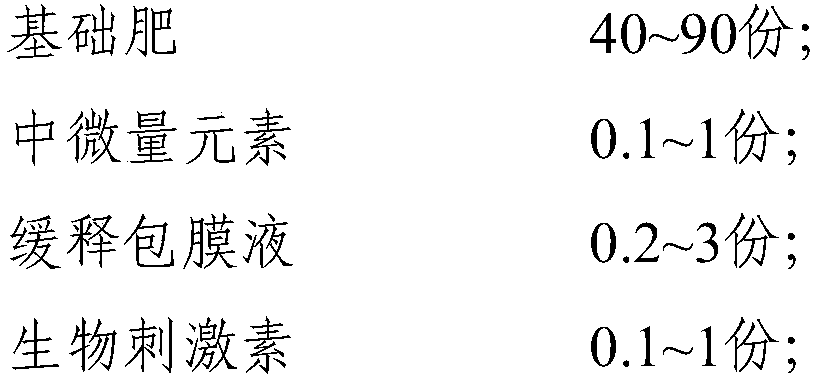

A special fertilizer and potato technology, which is applied in the field of potato long-acting slow-release special fertilizer and its preparation, can solve the problems of affecting food safety and human health, limiting potato yield and quality, and low utilization rate of potato fertilizer, so as to avoid soil nutrients The effect of enrichment, improving fertilizer utilization rate, and improving soil micro-ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

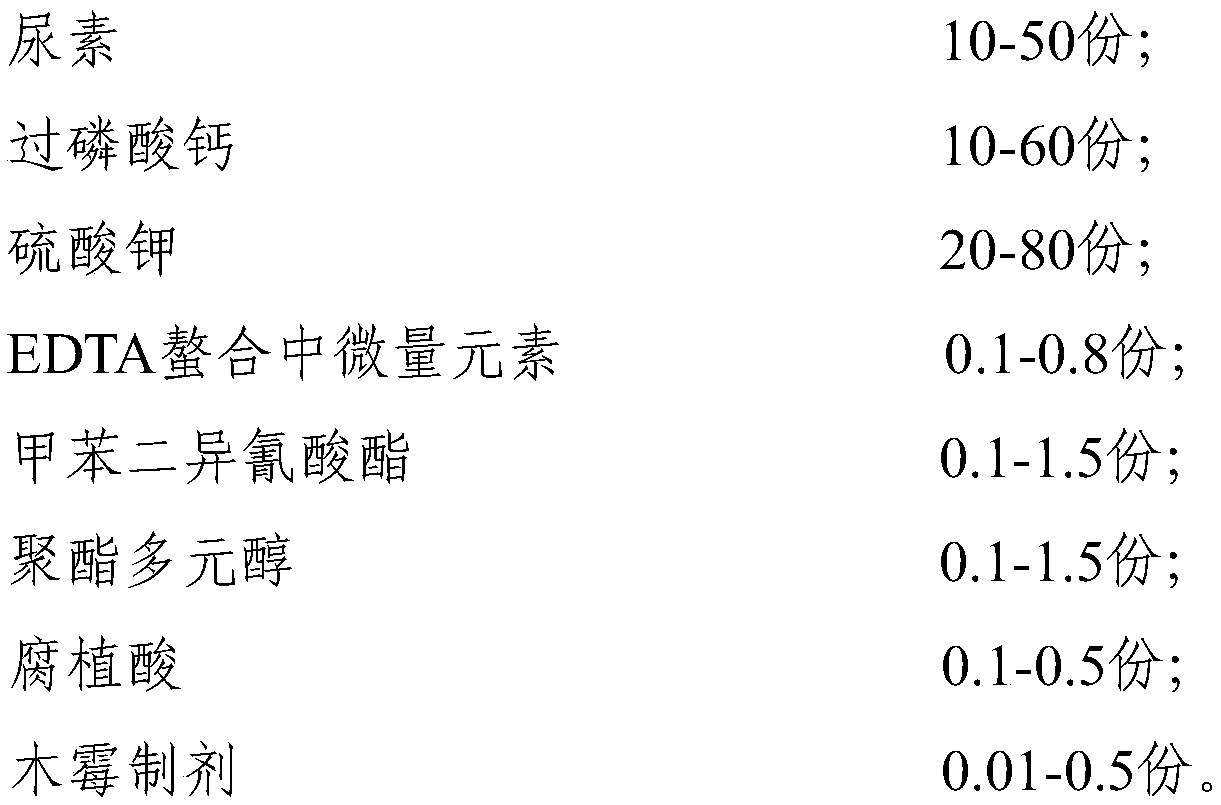

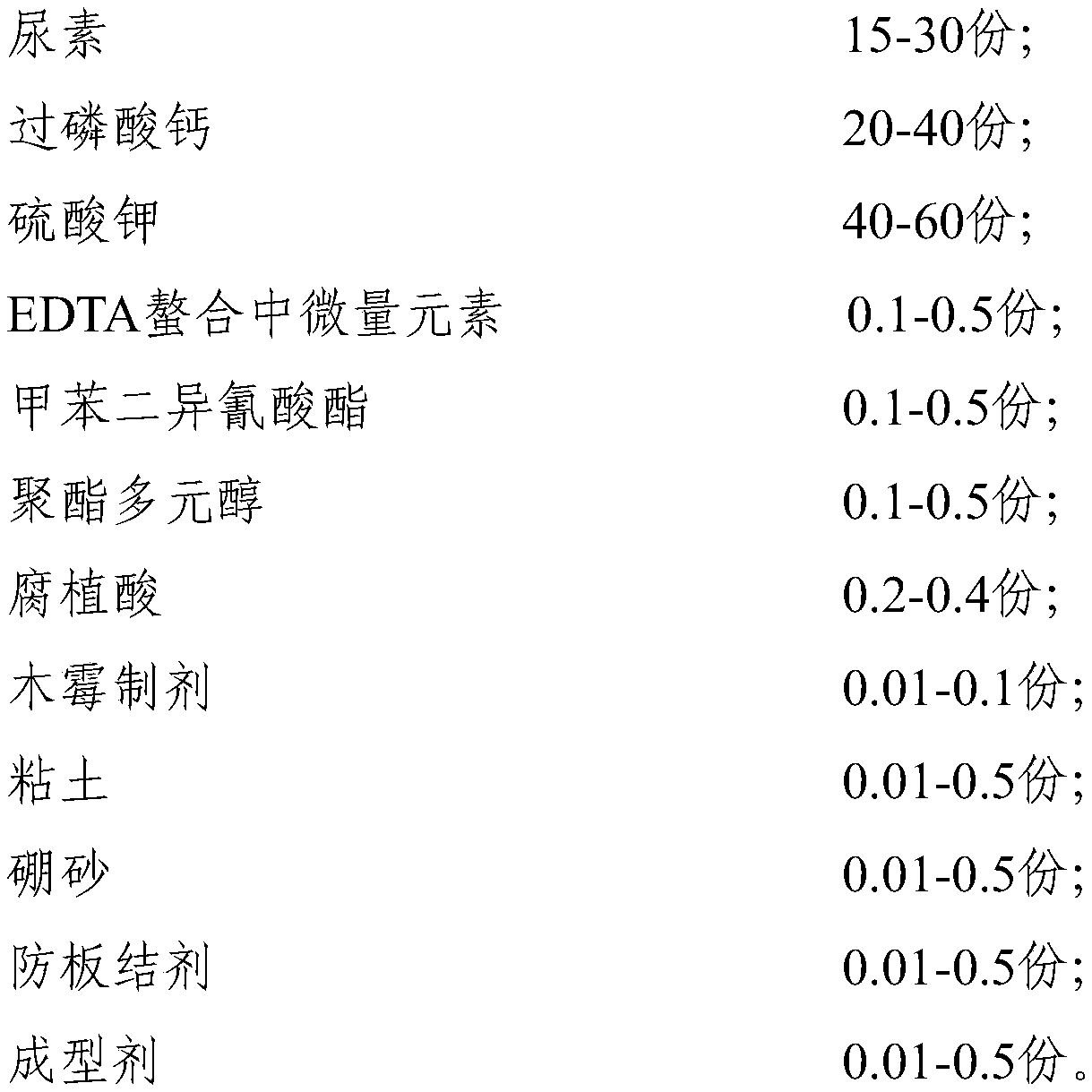

[0047] The present embodiment provides a special fertilizer for potatoes, the formula is as follows:

[0048] 20 parts of urea, 33 parts of superphosphate, 45 parts of potassium sulfate, 0.4 parts of trace elements in EDTA chelation, 0.4 parts of humic acid, 0.05 parts of Trichoderma preparation, 0.2 parts of polyester polyol, 0.2 parts of toluene diisocyanate, 0.2 parts of clay part, 0.2 part of borax, 0.2 part of anti-caking agent, and 0.2 part of forming agent.

[0049] The present embodiment also provides the preparation method of above-mentioned special-purpose fertilizer, specifically comprises the following steps:

[0050] (1) Prepare urea, superphosphate, potassium sulfate, humic acid, trace elements in EDTA chelation, clay and borax in proportion, and stir evenly.

[0051] (2) Send the uniformly stirred materials into the granulator for granulation, and the temperature in the granulation furnace is controlled at 180-200°C. The granules made by the granulator are sen...

Embodiment 2

[0055] The present embodiment provides a special fertilizer for potatoes, the formula is as follows:

[0056] 20 parts of urea, 33 parts of calcium superphosphate, 45 parts of potassium sulfate, 0.4 parts of trace elements in EDTA chelation, 0.2 parts of polyester polyol, 0.2 parts of toluene diisocyanate, 0.2 parts of clay, 0.2 parts of borax, 0.2 parts of anti-caking agent , 0.2 parts of molding agent.

[0057] The present embodiment also provides the preparation method of above-mentioned special-purpose fertilizer, specifically comprises the following steps:

[0058] (1) Prepare urea, superphosphate, potassium sulfate, trace elements in EDTA chelation, clay and borax in proportion, and stir evenly.

[0059] (2) Send the uniformly stirred materials into the granulator for granulation, and the temperature in the granulation furnace is controlled at 180-200°C. Send the granules made by the granulator to the dryer, control the temperature within 120°C, dry the moisture contai...

Embodiment 3

[0063] The present embodiment provides a special fertilizer for potatoes, the formula is as follows:

[0064] 20 parts of urea, 33 parts of superphosphate, 45 parts of potassium sulfate, 0.4 parts of humic acid, 0.05 parts of Trichoderma preparation, 0.2 parts of polyester polyol, 0.2 parts of toluene diisocyanate, 0.2 parts of clay, 0.2 parts of borax, anti-caking agent 0.2 parts, 0.2 parts of forming agent.

[0065] The present embodiment also provides the preparation method of above-mentioned special-purpose fertilizer, specifically comprises the following steps:

[0066] (1) Prepare urea, superphosphate, potassium sulfate, humic acid, clay and borax according to a certain ratio, and stir evenly.

[0067] (2) Send the uniformly stirred materials into the granulator for granulation, and the temperature in the granulation furnace is controlled at 180-200°C. The granules made by the granulator are sent to the dryer, the temperature is controlled within 120°C, the moisture co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com