Slow-release controllable polycarboxylate superplasticizer mother liquor and preparation method thereof

A technology of polycarboxylic acid and water reducer, which is applied in the field of admixtures for cement-based building materials, and can solve the problems of cement slurry bleeding, hardening, and the inability to accurately control the initial fluidity of cement slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Experimental study on the synthesis of mother liquor of slow-release and controllable polycarboxylate superplasticizer, using large monomer TPEG, small diester monomer, small monoester monomer, functional monomer, oxidizing agent, reducing agent, and chain transfer agent for synthesis Research, in which the small diester monomers use polyethylene glycol bismaleic acid monoester DD1 or polyethylene glycol diacrylate DD2, the monoester small monomers use hydroxyethyl acrylate XD1, and the functional monomers use acrylic acid GN , the oxidizing agent selects hydrogen peroxide for use, the reducing agent selects VC for use, and the chain transfer agent selects mercaptopropionic acid for use, and the preparation method comprises the following steps:

[0032] 1) Weighing synthetic raw materials in proportion,

[0033] 2) Put the macromonomer TPEG, small diester monomers, and small monoester monomers into the reactor, stir and mix evenly, and control the reaction temperature t...

Embodiment 2

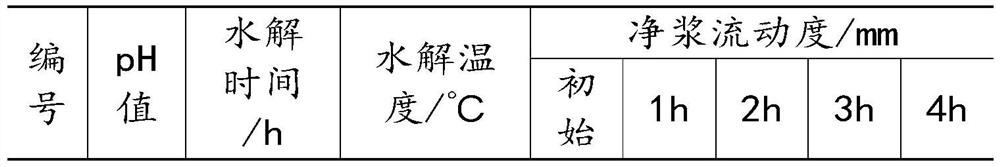

[0044] Select the mix ratio of number 4 in Example 1, adjust the hydrolysis pH value, hydrolysis time and hydrolysis temperature, and study the influence of hydrolysis parameters in step 6) of the preparation method on the performance of the polycarboxylate superplasticizer mother liquor, referring to GB / T 8077-2012 " Test method for homogeneity of concrete admixtures" to test the fluidity of cement paste, the mother liquor content is 0.7%. The obtained results are shown in Table 2.

[0045] Table 2 influence of hydrolysis parameters

[0046]

[0047]

[0048] The hydrolysis process of branched-chain ester groups of polycarboxylate superplasticizers is an endothermic process. The higher the pH value, the higher the temperature, and the longer the time, the more ester groups are hydrolyzed. The mother liquor promotes the initial fluidity of the cement slurry, and the ester group remaining in the polycarboxylate superplasticizer polymer continues to hydrolyze during the c...

Embodiment 3

[0050] The polycarboxylate superplasticizer mother liquor with the ratio of No. 4 and No. 9 in Example 1 was subjected to a self-compacting concrete test, and a sodium gluconate retarder and a cellulose ether water-retaining agent were prepared to form a water-retaining slow-release product with a solid content of 20%. PC-type polycarboxylate superplasticizer PC, using 42.5 grade ordinary Portland cement, machine-made sand (powder content ≤ 6%), washed river sand (fineness modulus 2.6), continuous gradation of stones from 5 to 20mm, powder The coal ash is grade II, and the mineral powder is grade S95. The mix ratio of self-compacting concrete is shown in Table 3.

[0051] Table 3 Self-compacting concrete mix ratio (kg / m3)

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com