Enrichment and separation method of heavy-nucleus hydrogen isotopes

A hydrogen isotope and separation method technology, applied in the field of heavy nuclear hydrogen isotope enrichment and separation, can solve the problems of low separation capacity, long separation cycle, incomplete desorption of separation column, etc., and achieve the effect of easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

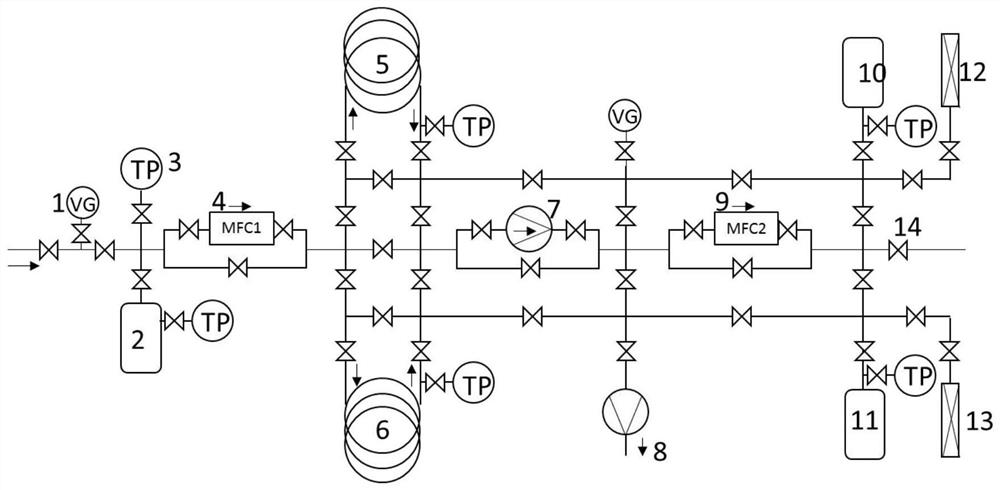

[0106] figure 1 A schematic diagram of a device for the separation of heavy nuclear hydrogen isotopes used in the present invention, such as figure 1 As shown, including 1-vacuum pump (VG), 2-raw material tank, 3 or TP-temperature, pressure sensor, 4-mass flow controller 1 (MFC1), 5-separation column 1, 6-separation column 2, 7- Transfer pump, 8-vacuum pump, 9-mass flow controller 2 (MFC2), 10-tail gas tank, 11-product tank, 12-tail gas transfer bed, 13-product gas transfer bed, 14-valve, the arrow points to the gas flow direction .

[0107] Separation column 1 and separation column 2 are both made of stainless steel tubes with a length of 10m, an inner diameter of 10mm and a thickness of 2mm to make spiral tubes with a middle diameter of 250mm, and are filled with 5A molecular sieve columns with an average inner diameter of 2.18mm, and the charging amount is 0.5kg , material bulk density is 650kg / m 3 .

[0108] The raw material composition of hydrogen isotope mixed gas to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com