Toughened antistatic dual-functional plastic master batch for direct injection molding and preparation method thereof

A technology of injection molding and plastic masterbatch, applied in the field of toughening and antistatic bifunctional plastic masterbatch and its preparation, can solve the problems of difficult toughening modification, decreased toughening effect, low elastic ionomer melt strength, etc. , to achieve the effect of being beneficial to the toughening effect, enhancing the toughening effect and reducing the deformation of the dispersed phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

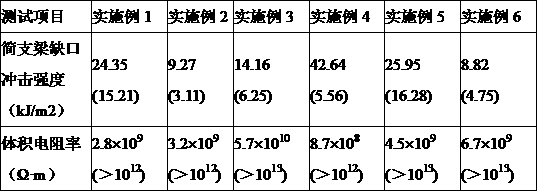

Examples

Embodiment 1

[0030] A toughened and antistatic dual-functional plastic masterbatch for direct injection molding and a preparation method thereof, the mass ratio of its raw materials is as follows:

[0031] Calcium ion cross-linked ethylene-methacrylic acid copolymer elastic ionomer 83.0kg

[0032] Zinc ion cross-linked sulfonated three-arm telechelic polybutadiene ionomer 5.12kg

[0033] K30 polyvinylpyrrolidone 6.0kg

[0034] LDPE 5.0kg

[0035] Dicumyl peroxide 0.08kg

[0037] Polyethylene wax 0.5kg

[0038] Calcium ion cross-linked ethylene-methacrylic acid copolymerized elastic ionomer, zinc ion cross-linked sulfonated three-arm telechelic polybutadiene ionomer, K30 polyvinylpyrrolidone, low density Put polyethylene, dicumyl peroxide, calcium stearate and polyethylene wax into the high-speed mixer and mix evenly, then transfer to the internal mixer for thermal mixing, the mixing temperature is set at 135°C, and the mixing time is 16 minutes; then t...

Embodiment 2

[0040] A toughened and antistatic dual-functional plastic masterbatch for direct injection molding and a preparation method thereof, the mass ratio of its raw materials is as follows:

[0041] Zinc ion cross-linked ethylene-octene-acrylic acid copolymer elastic ionomer 76.15kg

[0042] Calcium ion cross-linked sulfonated three-arm telechelic polybutadiene ionomer 10.0kg

[0043] K25 Polyvinylpyrrolidone 3.0kg

[0044] Atactic polypropylene 10.0kg

[0045] Dicumyl peroxide 0.05kg

[0046] Stearic acid 0.5kg

[0047] Oxidized polyethylene wax 0.3kg

[0048] Zinc ion cross-linked ethylene-octene-acrylic acid copolymerized elastic ionomer, calcium ion cross-linked sulfonated three-arm telechelic polybutadiene ionomer, K25 polyvinylpyrrolidone, no Standard polypropylene, dicumyl peroxide, stearic acid and oxidized polyethylene wax were put into a high-speed mixer and mixed evenly, then transferred to an internal mixer for thermal mixing, and the mixing temperature was set at 1...

Embodiment 3

[0050] A toughened and antistatic dual-functional plastic masterbatch for direct injection molding and a preparation method thereof, the mass ratio of its raw materials is as follows:

[0051] Barium ion cross-linked ethylene-methacrylic acid copolymer elastic ionomer 75.0kg

[0052] Magnesium ion cross-linked sulfonated three-arm telechelic isoprene ionomer 10.0kg

[0053] K60 polyvinylpyrrolidone 5.62kg

[0054] LDPE 8.5kg

[0055] Dilauroyl peroxide 0.03kg

[0056] Zinc stearate 0.4kg

[0057] Oxidized polyethylene wax 0.45kg

[0058] Barium ion cross-linked ethylene-methacrylic acid copolymer elastic ionomer, magnesium ion cross-linked sulfonated three-arm telechelic isoprene ionomer, K60 polyvinylpyrrolidone, low density Polyethylene, dilauroyl peroxide, zinc stearate and oxidized polyethylene wax were put into a high-speed mixer and mixed evenly, then transferred to an internal mixer for thermal mixing, and the mixing temperature was set at 138°C. The time is 20 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com