Composition for eliminating skin stains as well as preparation method and application thereof

A composition and a technology for pigmentation, which are applied in the field of compositions for removing pigmentation on the skin, can solve the problems of excessive loss of skin moisture, damage to the stratum corneum of the skin, easy aging, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for a composition for removing skin pigmentation, comprising the following steps:

[0039] (1) Dried Chuanqiong, rose, lemon and white peony root in the sun, powdered them, added water at a solid-to-liquid ratio of 1:20, soaked for 10 hours, heated and refluxed to extract for 3-5 hours, filtered, and retained the filtrate; added water of equal quality to the filter residue , after heating to reflux for 2 hours, filter, discard the filter residue, combine the two filtrates, and concentrate to obtain a concentrated solution A with a specific gravity between 1.0-1.5;

[0040] (2) Add 6′-acetylated arbutin and vitamin E to the mixer, add deionized water, stir at 200r / min for 15min, continue to add egg white and pearl powder, stir at the same speed and disperse evenly, then add concentrated solution A, emulsify agent and antioxidant, heated to 60° C. and stirred for 2 hours, then cooled to room temperature, filled, sealed and stored to obtain a compositi...

Embodiment 16

[0042] Example 1 Preparation of 6′-acetylated arbutin

[0043] Raw material composition: arbutin, tetrahydrofuran, CSL lipase, vinyl acetate, all analytically pure, purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.;

[0044] Follow the steps below:

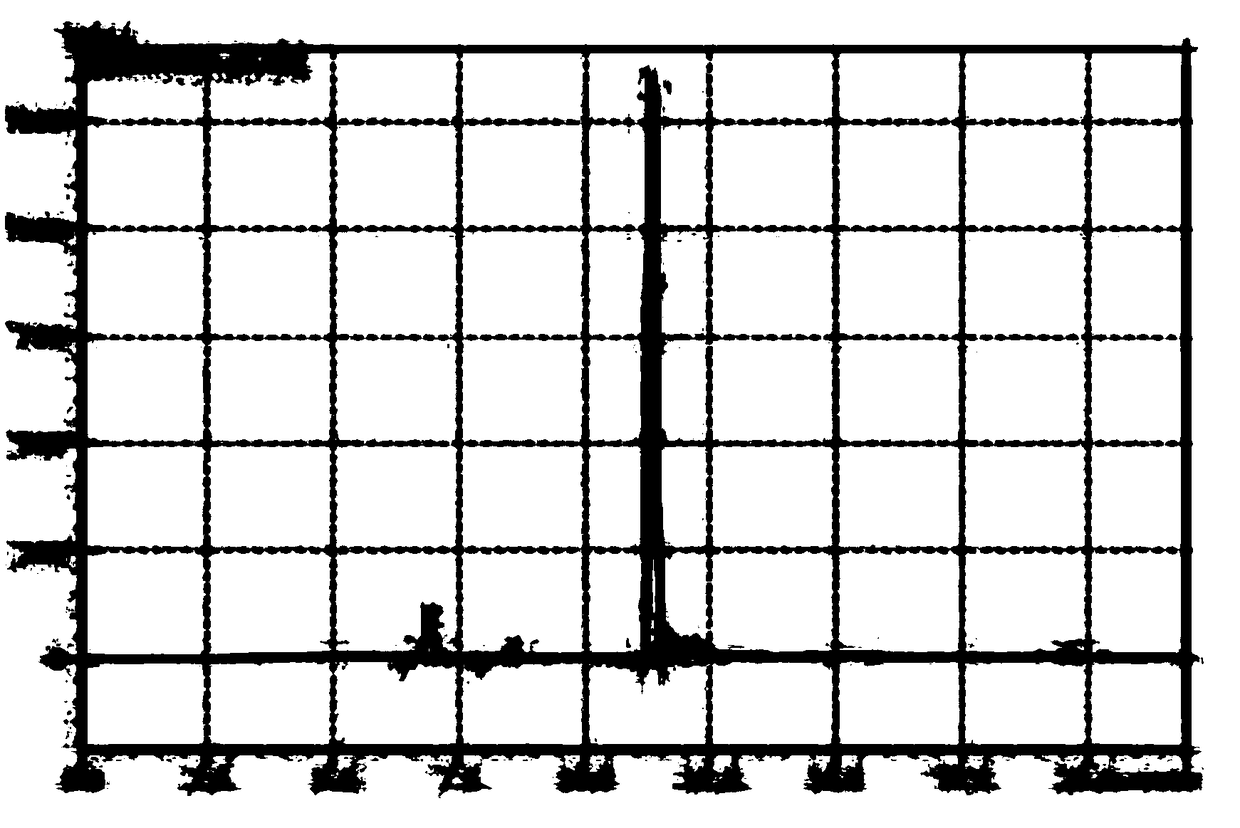

[0045] Add 0.73mmol arbutin, 30mmol vinyl acetate, and 100mg CSL lipase into a reactor filled with 20mL tetrahydrofuran, heat to 60°C with 400W microwave, and stir at 100r / min to react. The water activity of the reaction is 0.41, and the reaction time is 2.5 h, terminate the reaction, filter the enzyme with a 0.22 μm microporous membrane filter, and evaporate the solvent to dryness to get final product, the yield is 92.5%, and the HPLC figure of reaction monitoring is as attached figure 1 and 2 shown.

[0046] figure 1 For the HPLC chart of the substrate when the arbutin non-aqueous phase acetylation reaction is 0h, the retention time of the arbutin substrate is approximately 6.869min, and the peak area is about...

Embodiment 2

[0058] Example 2 Preparation of 6'-acetylated arbutin

[0059] Raw material composition: arbutin, thionyl chloride, Novozym 435 lipase, vinyl propionate, all analytically pure, purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.;

[0060] Follow the steps below:

[0061] Add 0.73mmol arbutin, 30mmol vinyl propionate, and 100mg Novozym 435 lipase into a reactor containing 20mL thionyl chloride, heat to 60°C with 400W microwave, and stir at 100r / min to react. The water activity of the reaction is 0.41, the reaction time was 2.5 hours, the reaction was terminated, the enzyme was filtered through a 0.22 μm microporous membrane, and the solvent was spun to dryness, and the yield was 83.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com