Efficient controlled-release fertilizer applicable to saline-alkali soil and preparation method thereof

A saline-alkaline soil and controlled-release fertilizer technology, applied in the field of high-efficiency controlled-release fertilizer and its preparation, can solve problems such as soil residue, poor controlled-release functionality, and accumulation of salt root ions, so as to enhance water retention capacity, reduce PH value, and enhance soil active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

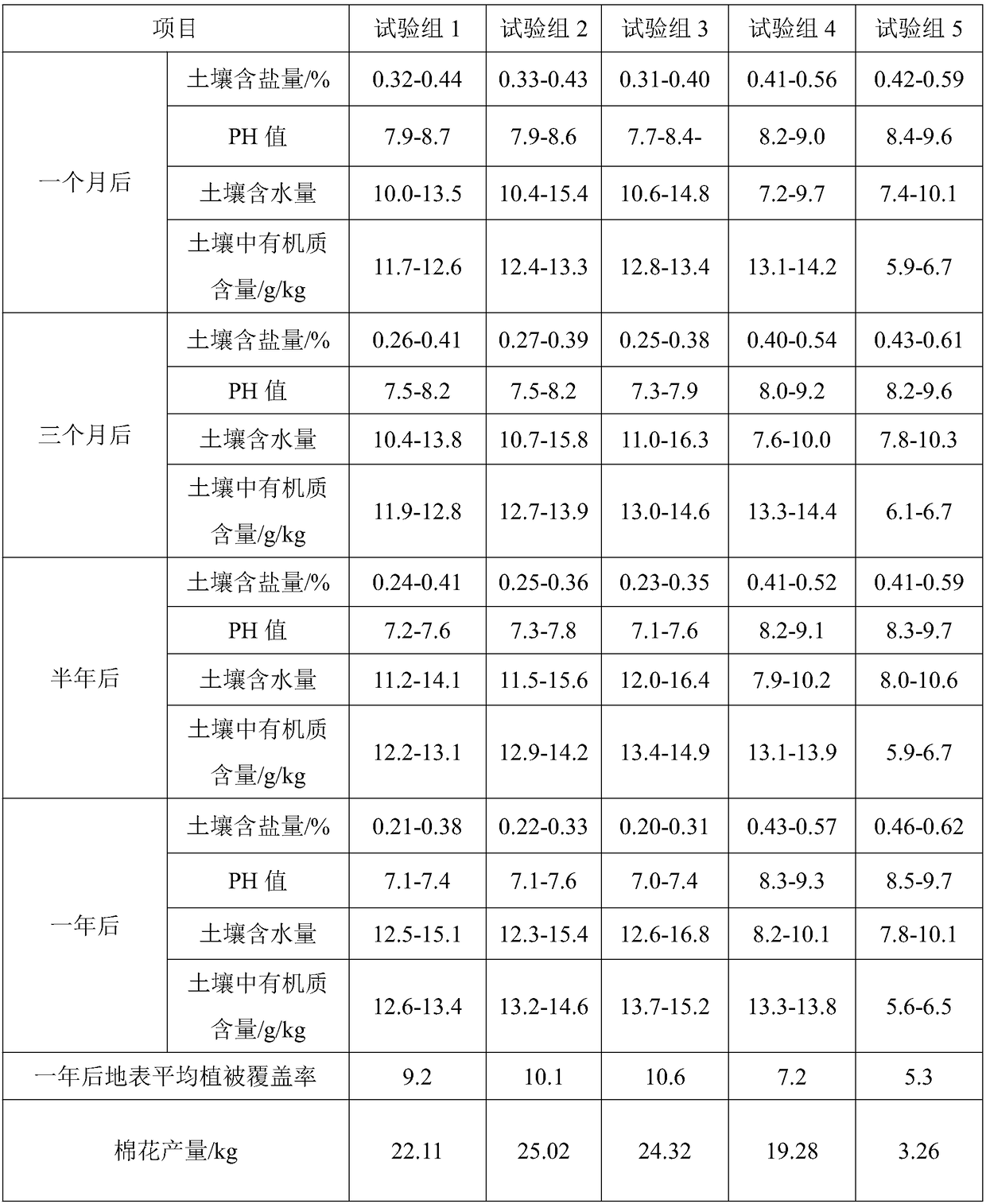

Embodiment 1

[0023] A high-efficiency controlled-release fertilizer suitable for saline-alkali soil, characterized in that it consists of the following raw material ratios in parts by mass: 10 parts of urea, 12 parts of potassium dihydrogen phosphate, 25 parts of tannic acid, 20 parts of elemental fertilizer, decomposed livestock 20 parts of manure, 15 parts of ammonium humate, 100 parts of straw ash, 5 parts of starch-based composite film, 5 parts of PAM, PVA solution of enhancer, glycerin of plasticizer and cross-linking agent.

[0024] The element fertilizer includes copper sulfate, zinc lignosulfonate, ferrous sulfate, magnesium sulfate, ammonium molybdate and manganese sulfate. The starch-based composite film is mainly a composite film prepared from cornstarch. The enhancer PVA The concentration of the solution is 40%, the concentration of the plasticizer glycerin is 20%, and the crosslinking agent is glyoxal with a concentration of 15%.

Embodiment 2

[0035] A high-efficiency controlled-release fertilizer suitable for saline-alkali soil according to the present invention is composed of the following raw material ratios in parts by mass: 15 parts of urea, 20 parts of potassium dihydrogen phosphate, 35 parts of tannic acid, 25 parts of elemental fertilizer, 35 parts of decomposed livestock manure, 20 parts of ammonium humate, 120 parts of straw ash, 10 parts of starch-based composite film, and 12 parts of PAM.

[0036] The element fertilizer includes copper sulfate, zinc lignosulfonate, ferrous sulfate, magnesium sulfate, ammonium molybdate and manganese sulfate, and its copper sulfate, zinc lignosulfonate, ferrous sulfate, magnesium sulfate, ammonium molybdate and sulfuric acid The mass-number ratio of manganese is: 1:2.5:2.5:2.1.2:0.8.

[0037] The preparation method of the high-efficiency controlled-release fertilizer and the preparation method of the starch-based composite film and the fermented bacterial agent in this ex...

Embodiment 3

[0039] A high-efficiency controlled-release fertilizer suitable for saline-alkali soil according to the present invention is composed of the following raw material ratios in parts by mass: 12 parts of urea, 16 parts of potassium dihydrogen phosphate, 30 parts of tannic acid, 22 parts of elemental fertilizer, 28 parts of decomposed livestock manure, 17 parts of ammonium humate, 110 parts of straw ash, 7 parts of starch-based composite film, and 8 parts of PAM.

[0040] The element fertilizer includes copper sulfate, zinc lignosulfonate, ferrous sulfate, magnesium sulfate, ammonium molybdate and manganese sulfate, and its copper sulfate, zinc lignosulfonate, ferrous sulfate, magnesium sulfate, ammonium molybdate and sulfuric acid The mass-to-number ratio of manganese is: 1:2:1.6:1.6:1.1:0.7.

[0041] The preparation method of the high-efficiency controlled-release fertilizer and the preparation method of the starch-based composite film and the fermented bacterial agent in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com