Method for preparing furoic acid and 5-hydroxymethyl furoic acid by biomasses

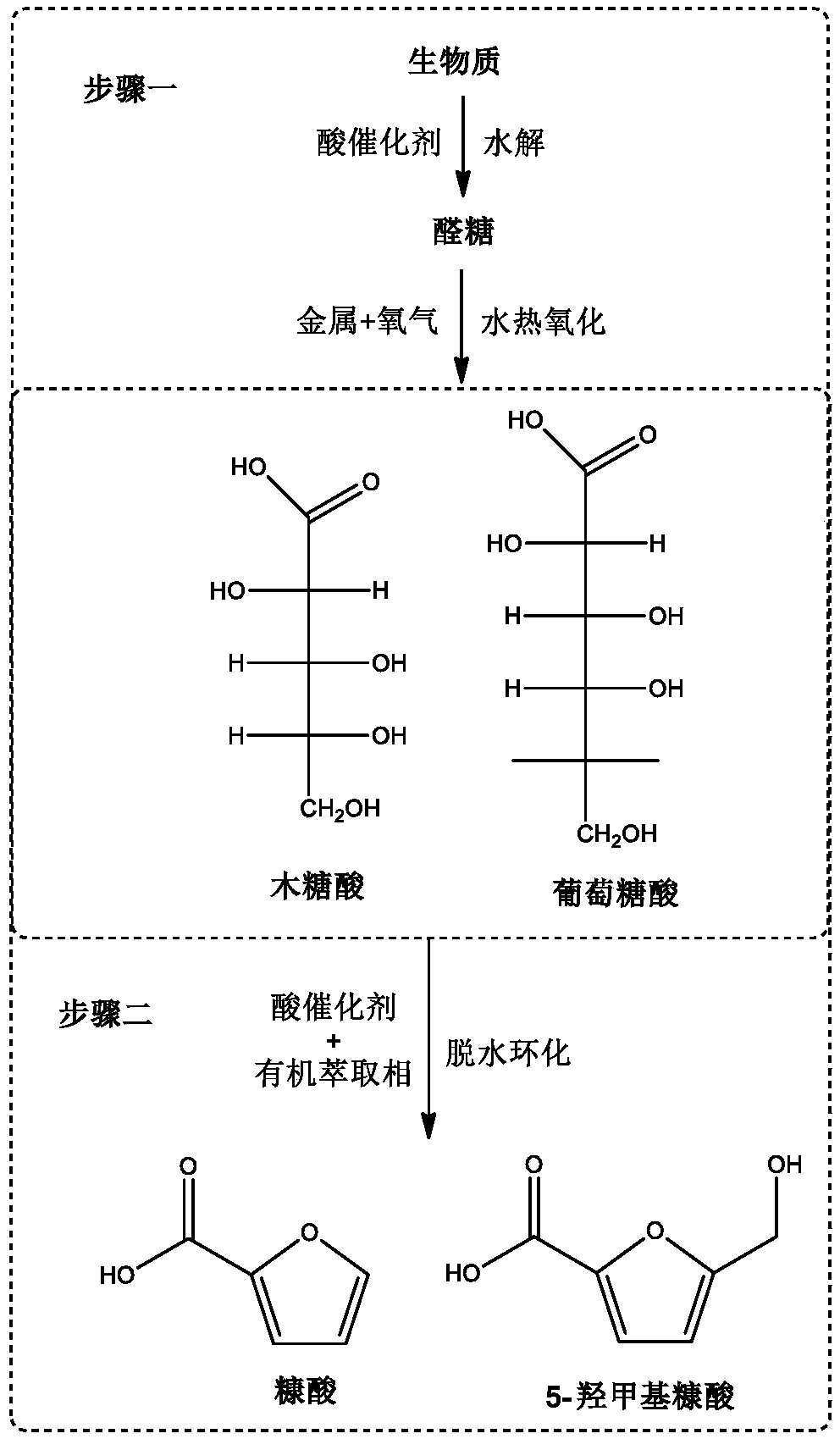

A technology of hydroxymethyl furfural acid and biomass, applied in the field of biomass chemistry, can solve the problems of cumbersome separation process, high separation energy consumption, unindustrialization of 5-hydroxymethyl furfural and 5-hydroxymethyl furoic acid, etc. , to achieve the effect of easy operation, easy availability of raw materials, and avoiding low target products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) One-step hydrothermal oxidation of corn stalks to gluconic acid and xylonic acid

[0028] Add 2.0 g of corn stalks, 0.1 g of Au / C catalyst and 25 mL of deionized water into a 50 mL stirred reactor, and conduct hydrothermal oxidation of corn stalks at 200 °C and 0.3 MPa in air for 2 h to obtain gluconic acid and xylose Acid degradation solution, wherein the yield of gluconic acid reaches 54%, and the yield of xylonic acid reaches 61%.

[0029] (2) Preparation of 5-hydroxymethylfuroic acid and furoic acid by degradation liquid two-phase method

[0030] The degradation liquid obtained in step (1) was transferred to a 100 mL stirred reactor, and 0.2 g of sodium bisulfate, 0.4 g of zinc sulfate and 25 mL of tetrahydrofuran were added, and then the mixed liquid was hydrothermally degraded at 160 ° C for 4 h to obtain 34 % 5-Hydroxymethylfuroic acid and 40% furoic acid (relative to cellulose and hemicellulose in corn stover).

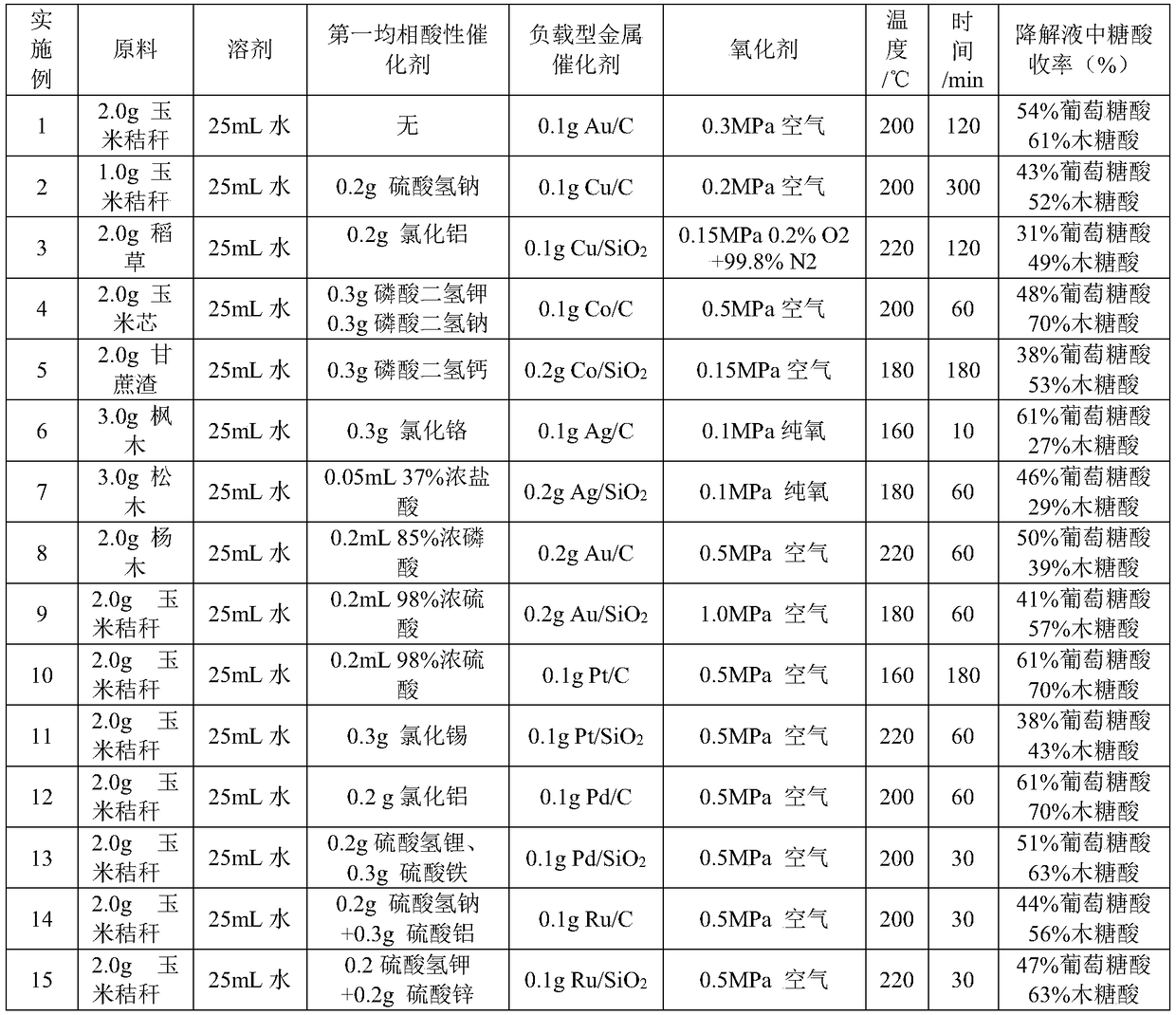

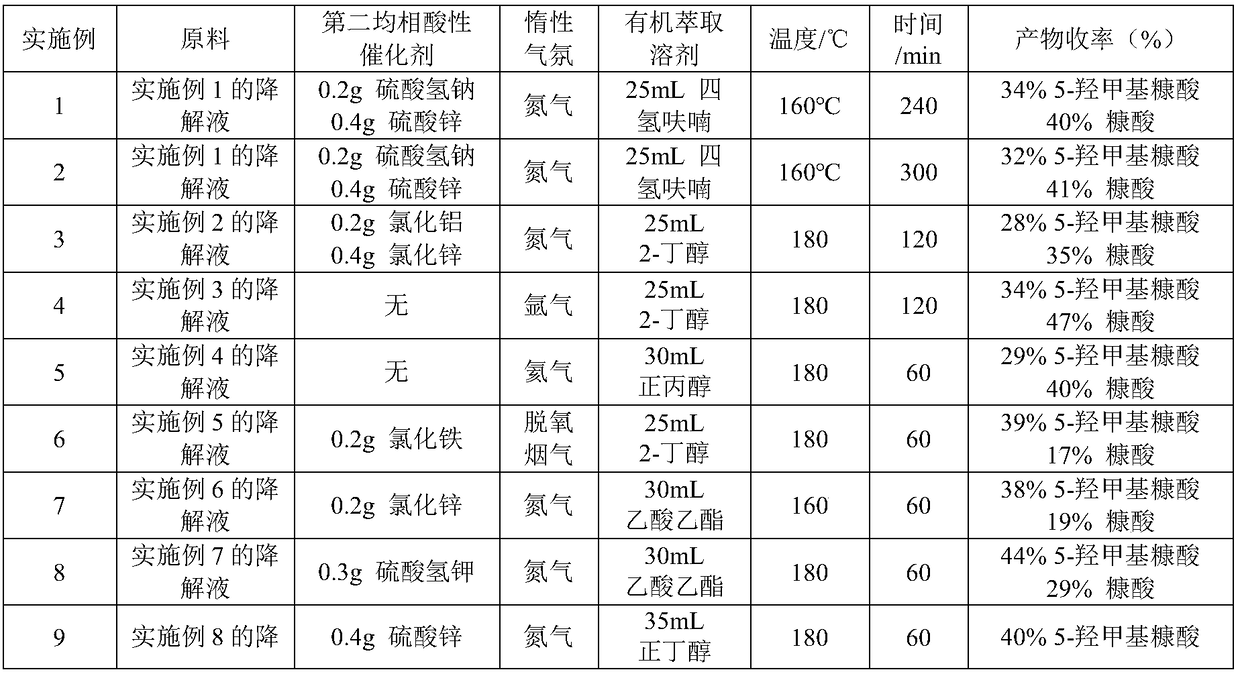

Embodiment 2~15

[0032] The reaction step of embodiment 2~15 is identical with embodiment 1, and reaction condition and reaction result are as shown in table 1 and table 2, and table 1 is the reaction condition and sugar acid yield of embodiment 1~15 steps (1), namely The yield of sugar acid in the degradation solution rich in sugar acid obtained by catalytic degradation of various biomass raw materials in a 50mL high-pressure stirred reactor; Table 2 is the degradation solution containing gluconic acid and / or xylonic acid obtained in step (1). The reaction conditions and the yields of furoic acid and 5-hydroxymethylfuroic acid were catalytically converted into furoic acid and 5-hydroxymethylfuroic acid in a 100mL stirred reactor. The yield of gluconic acid and xylonic acid in table 1 is relative to the quality of cellulose and hemicellulose in the biomass raw material; the yield of furoic acid and 5-hydroxymethyl furoic acid in table 2 is relative to raw In terms of the quality of cellulose a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com