A kind of antibacterial polyester fiber lining cloth and its production process

A polyester fiber and production process technology, applied in the field of antibacterial polyester interlining and its production process, can solve the problems of limited addition, limited antibacterial durability, poor durability, etc., reduce tension fluctuations, improve weaving efficiency, and improve The effect of antimicrobial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

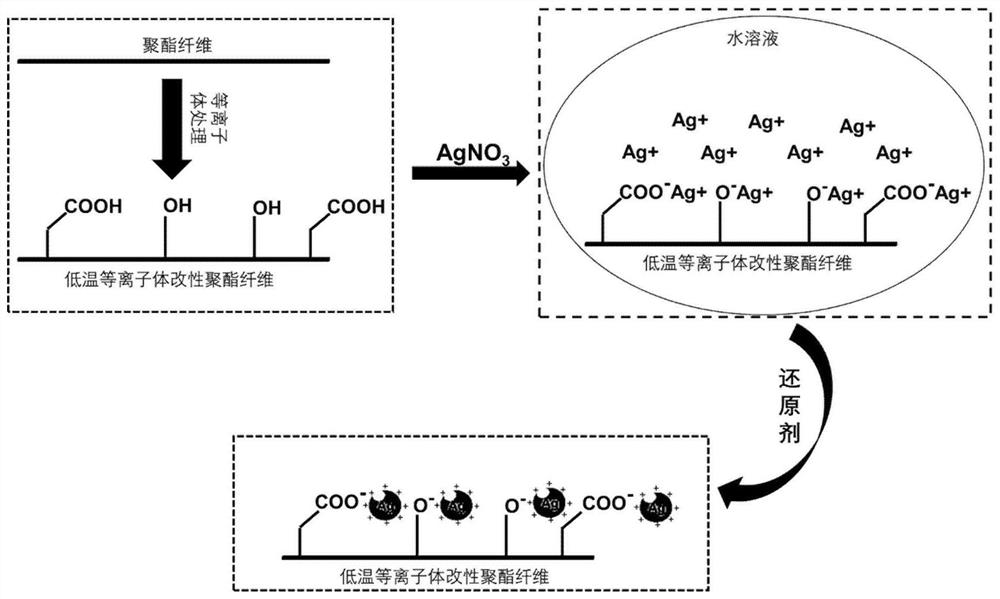

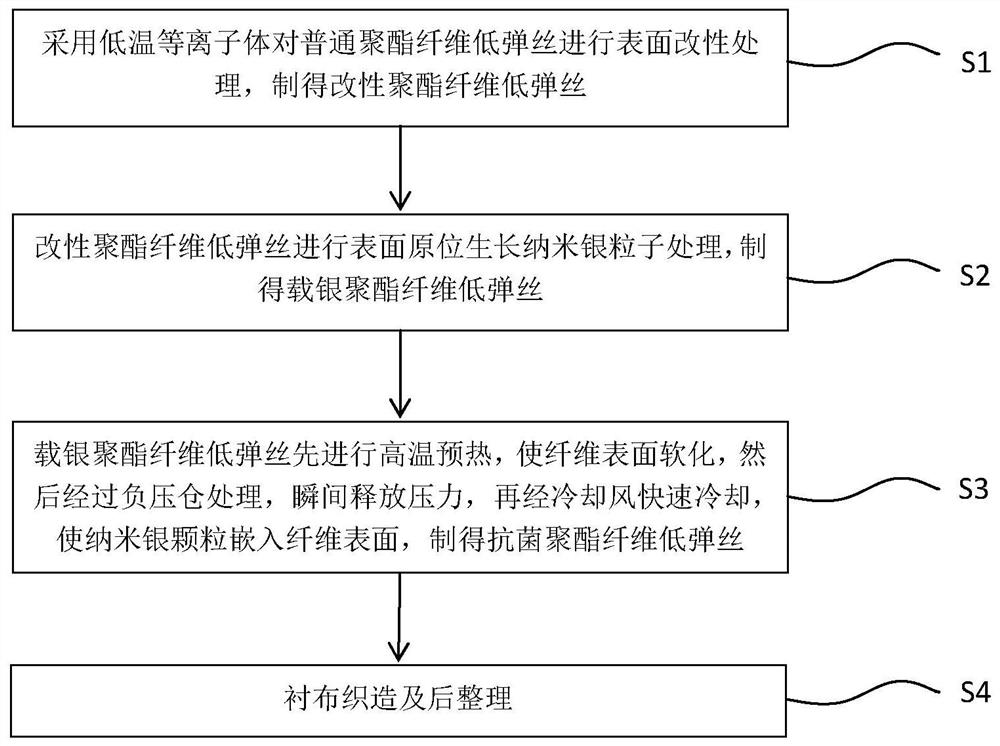

[0059] Such as figure 2 Shown, a kind of production technology of antibacterial polyester interlining comprises the following steps:

[0060] S1. Using low-temperature plasma to modify the surface of ordinary polyester fiber low-elasticity yarns, the fineness of ordinary polyester fiber low-elasticity yarns is 15D, and preparing modified polyester fiber low-elasticity yarns.

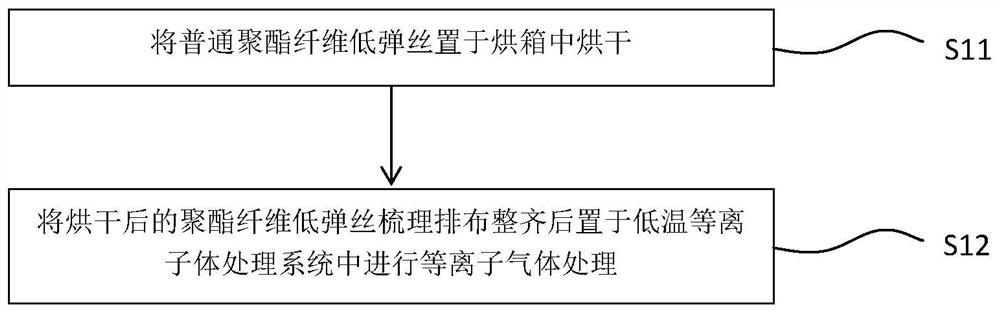

[0061] Such as image 3 Shown, the preparation of modified polyester fiber low elastic yarn comprises the following steps:

[0062] S11. Dry the ordinary polyester fiber low-stretch yarn in an oven at 60°C. The moisture regain of the polyester fiber low-stretch yarn is very low, but a small amount of water molecules have hydrogen bonds in the polyester fiber low-stretch yarn It is difficult to get out and needs high temperature to dry;

[0063] S12. After combing and arranging the dried polyester fiber low-elastic yarns neatly, place them in a low-temperature plasma treatment system for plasma gas tr...

Embodiment 2

[0081] Such as figure 2 Shown, a kind of production technology of antibacterial polyester interlining comprises the following steps:

[0082] S1. Using low-temperature plasma to modify the surface of ordinary polyester fiber low-elasticity yarns, the fineness of ordinary polyester fiber low-elasticity yarns is 50D, and preparing modified polyester fiber low-elasticity yarns.

[0083] Such as image 3 Shown, the preparation of modified polyester fiber low elastic yarn comprises the following steps:

[0084] S11. Dry the ordinary polyester fiber low-stretch yarn in an oven at 75°C. The moisture regain of the polyester fiber low-stretch yarn is very low, but a small amount of water molecules have hydrogen bonds in the polyester fiber low-stretch yarn It is difficult to get out and needs high temperature to dry;

[0085] S12. After combing and arranging the dried polyester fiber low-elastic yarns neatly, place them in a low-temperature plasma treatment system for plasma gas tr...

Embodiment 3

[0102] Such as figure 2 Shown, a kind of production technology of antibacterial polyester interlining comprises the following steps:

[0103] S1. Using low-temperature plasma to modify the surface of ordinary polyester fiber low-elasticity yarns, the fineness of ordinary polyester fiber low-elasticity yarns is 25-35D, and preparing modified polyester fiber low-elasticity yarns.

[0104] Such as image 3 Shown, the preparation of modified polyester fiber low elastic yarn comprises the following steps:

[0105] S11. Put ordinary polyester fiber low-stretch yarn in an oven to dry at 90°C. The moisture regain of polyester fiber low-stretch yarn is very low, but a small amount of water molecules have hydrogen bonds in polyester fiber low-stretch yarn It is difficult to get out and needs high temperature to dry;

[0106] S12. After combing and arranging the dried polyester fiber low-elastic yarns neatly, place them in a low-temperature plasma treatment system for plasma gas trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com