Preparation method of low-temperature flexible polymer solid electrolyte membrane and application of electrolyte membrane to low-temperature solid lithium ion battery

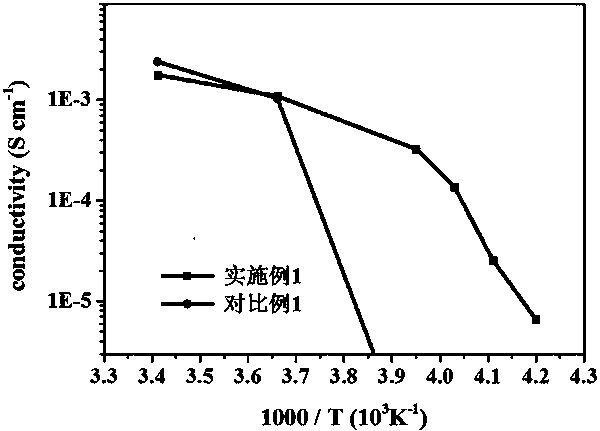

A technology of solid electrolyte membrane and lithium ion battery, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, solid electrolyte, etc., can solve the problems of low low temperature conductivity and poor flexibility, and achieve good conductivity and flexibility, excellent low temperature Effects of Toughness and Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

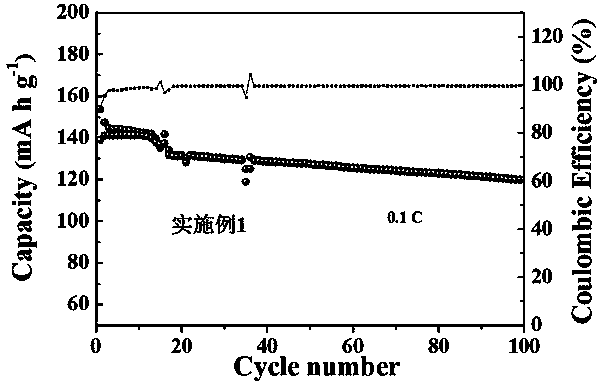

Embodiment 1

[0028] Preparation of positive electrode sheet:

[0029] According to the mass percentage of 80:3:7:10, add the positive electrode active material lithium iron phosphate, conductive agent acetylene black, lithium salt lithium perchlorate and binder modified polyvinyl chloride TPE into an appropriate amount of solvent NMP to make a slurry The material was uniformly ball-milled and coated on an aluminum foil, then dried in an oven at 80°C for 30 minutes, and then dried in a vacuum oven at 110°C for 24 hours to obtain a positive electrode sheet.

[0030] The preparation method of the low-temperature flexible polymer solid-state electrolyte membrane comprises the following steps:

[0031] Step S1: Dissolve 2 g of modified polyvinyl chloride TPE and 1 g of lithium salt LiTFSI in an appropriate amount of solvent tetrahydrofuran and stir evenly to obtain a clear viscous solution;

[0032] Step S2: Add 1 g of plasticizer diethyl phthalate DEP to the viscous solution obtained in Step ...

Embodiment 2

[0039] Preparation of positive electrode sheet:

[0040] According to the mass percentage of 80:3:7:10, the positive electrode active material lithium cobaltate, conductive agent acetylene black, lithium salt lithium perchlorate and binder modified polyvinyl chloride TPE are added to an appropriate amount of solvent NMP, and adjusted to The slurry was uniformly ball-milled and coated on an aluminum foil, then dried in an oven at 80°C for 30 minutes, and then dried in a vacuum oven at 110°C for 24 hours to obtain a positive electrode sheet.

[0041] The preparation method of the low-temperature flexible polymer solid-state electrolyte membrane comprises the following steps:

[0042] Step S1: Dissolve 2 g of modified polyvinyl chloride TPE / polyvinyl fluoride PVF mixture and 0.2 g of lithium salt LiTFSI in an appropriate amount of solvent acetonitrile and stir evenly to obtain a clear viscous solution;

[0043] Step S2: Add 0.6 g of plasticizer ethylene carbonate EC to the viscous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com