Terpene alcohol and chitosan-containing bactericidal composition and preparation method and application thereof

A fungicide composition and chitosan technology, applied in the field of pesticides, can solve problems such as research and application that have not been reported in public literature, and achieve the effects of obvious synergistic effect, increased action rate, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

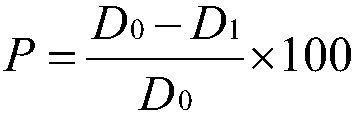

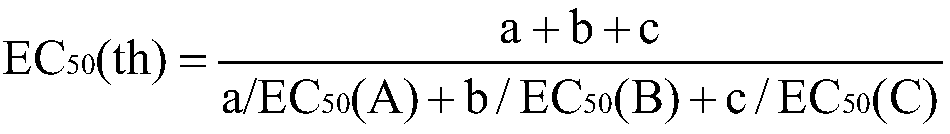

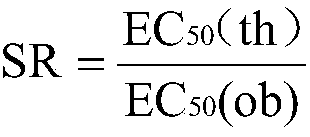

Method used

Image

Examples

Embodiment 1

[0035] Example 1 (10% terpene alcohol chitosan L-α-terpineol microemulsion)

[0036] The raw material formula of the present embodiment is:

[0037] Terpene alcohol 6%, chitosan 1%, L-α-terpineol 3%, N-methylpyrrolidone 8%, sodium dodecylbenzenesulfonate 6%, alkylaryl polyoxypropylene polyoxygen Vinyl ether 12%, propylene glycol 5%, and the balance is water.

[0038] The preparation method of this embodiment is:

[0039] Fully stir and dissolve terpene alcohol, L-α-terpineol, N-methylpyrrolidone, sodium dodecylbenzenesulfonate, alkylaryl polyoxypropylene polyoxyethylene ether, and propylene glycol in a container to prepare a uniform the oil phase. Stir and mix chitosan and water in a container to prepare a uniform water phase. Finally, slowly add the oil phase into the water phase of the formulation amount, mix and stir for 1 hour, and obtain a composition microemulsion with an active ingredient content of 10%.

Embodiment 2

[0040]Example 2 (22% terpene alcohol chitosan L-α-terpineol microemulsion)

[0041] The raw material formula of the present embodiment is:

[0042] Terpene alcohol 10%, chitosan 2%, L-α-terpineol 10%, chloroform 14%, calcium dodecylbenzenesulfonate 5%, phenylethylphenol polyoxyethylene ether 3%, fatty acid glycerin 2% ester, 2% ethylene glycol, 1% propylene glycol, and the balance is water.

[0043] The preparation method of this embodiment is:

[0044] Fully stir and dissolve terpene alcohol, L-α-terpineol, calcium dodecylbenzenesulfonate, phenethylphenol polyoxyethylene ether, fatty acid glyceride, ethylene glycol, and propylene glycol in a container to prepare a uniform oily phase. Stir and mix chitosan and water in a container to prepare a uniform water phase. Afterwards, the oil phase was slowly added into the water phase of the formulation amount, mixed and stirred for 1.5 hours to obtain a composition microemulsion with an active ingredient content of 17%.

Embodiment 3

[0045] Example 3 (20% terpene alcohol chitosan L-α-terpineol aqueous emulsion)

[0046] The raw material formula of the present embodiment is:

[0047] Terpene alcohol 9%, chitosan 1%, L-α-terpineol 10%, calcium dodecylbenzenesulfonate 5%, dibenzyl biphenyl polyoxyethylene ether 10%, xylene 10% , isooctyl alcohol 0.5%, ethylene glycol 1%, sorbitol 1%, polyvinyl alcohol 1%, and the balance is water.

[0048] The preparation method of this embodiment is:

[0049] Xylene, terpene alcohol, L-α-terpineol, calcium dodecylbenzenesulfonate, dibenzyl biphenyl polyoxyethylene ether, isooctyl alcohol, ethylene glycol, sorbitol, and polyvinyl alcohol are sequentially Add it into the reaction container, stir evenly and completely dissolve to obtain the oil phase, stir and mix the chitosan and water in the container to prepare a uniform water phase. Under the high-shear condition of the homogenizer (rotating speed: 4000-5000r / min), slowly add the oil phase to the water phase, after the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com