A preparation method for in-situ synthesis of high-concentration and strong bactericidal ZNO composite aqueous dispersion

An aqueous dispersion, in-situ synthesis technology, applied in the fields of botanical equipment and methods, fungicides, chemical instruments and methods, etc., can solve the problems of short storage time, high technical requirements of equipment, poor product stability, etc. Wide-ranging, reproducible, and simple to synthesize novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

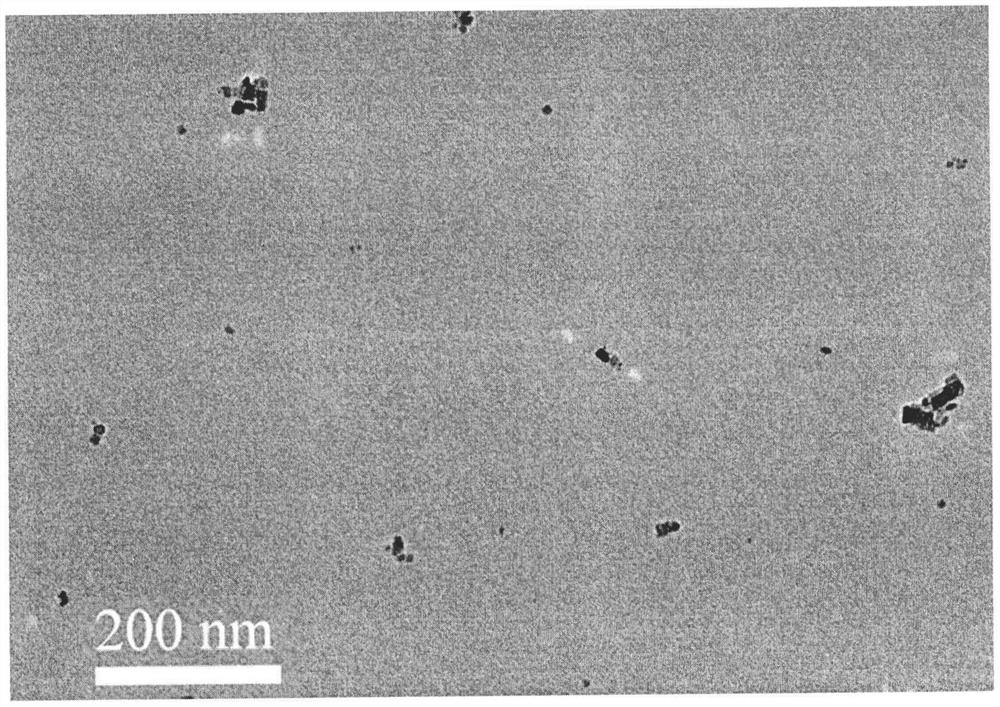

Image

Examples

Embodiment 1

[0022] Dissolve 1g of 5,5-dimethylhydantoin in water, add 10g of zinc chloride, the solution is a turbid solution, add NaOH to adjust the solution to alkaline pH=7, at this time the solution becomes a transparent solution, forming zinc ions stable complex. Then add 0.5g of nanoparticle protective agent polyvinylpyrrolidone, 0.5g of sodium polyacrylate and stir evenly, continue to add NaOH to stabilize the pH value at 7, and add deionized water to the solution until the total weight of the dispersion is 1kg, and stir for 6h to obtain Zinc oxide composite dispersion.

Embodiment 2

[0024] Dissolve 5g of 5,5-dimethylhydantoin in water, add 50g of zinc chloride, the solution is a turbid solution, add NaOH to adjust the solution to alkaline pH=8, at this time the solution becomes a transparent solution, forming zinc ions stable complex. Then add 2.5g of nanoparticle protective agent polyvinylpyrrolidone, 2.5g of sodium polyacrylate and stir evenly, continue to add triethanolamine to stabilize the pH value at 8, and add deionized water to the solution until the total weight of the dispersion is 500g, stir for 8h, that is Obtain zinc oxide composite dispersion liquid.

Embodiment 3

[0026] Dissolve 10g of 5,5-dimethylhydantoin in water, add 400g of zinc chloride, the solution is a turbid solution, add NaOH to adjust the solution to alkaline pH=8, at this time the solution becomes a transparent solution, forming zinc ions stable complex. Then add 5g of nanoparticle protective agent polyvinylpyrrolidone, 5g of sodium polyacrylate and stir evenly, continue to add AMP-95 to stabilize the pH value at 8, and add deionized water to the solution until the total weight of the dispersion is 1kg, and stir for 10h to obtain Zinc oxide composite dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com