Pet nutrient paste prepared through pandalus borealis processing by-products

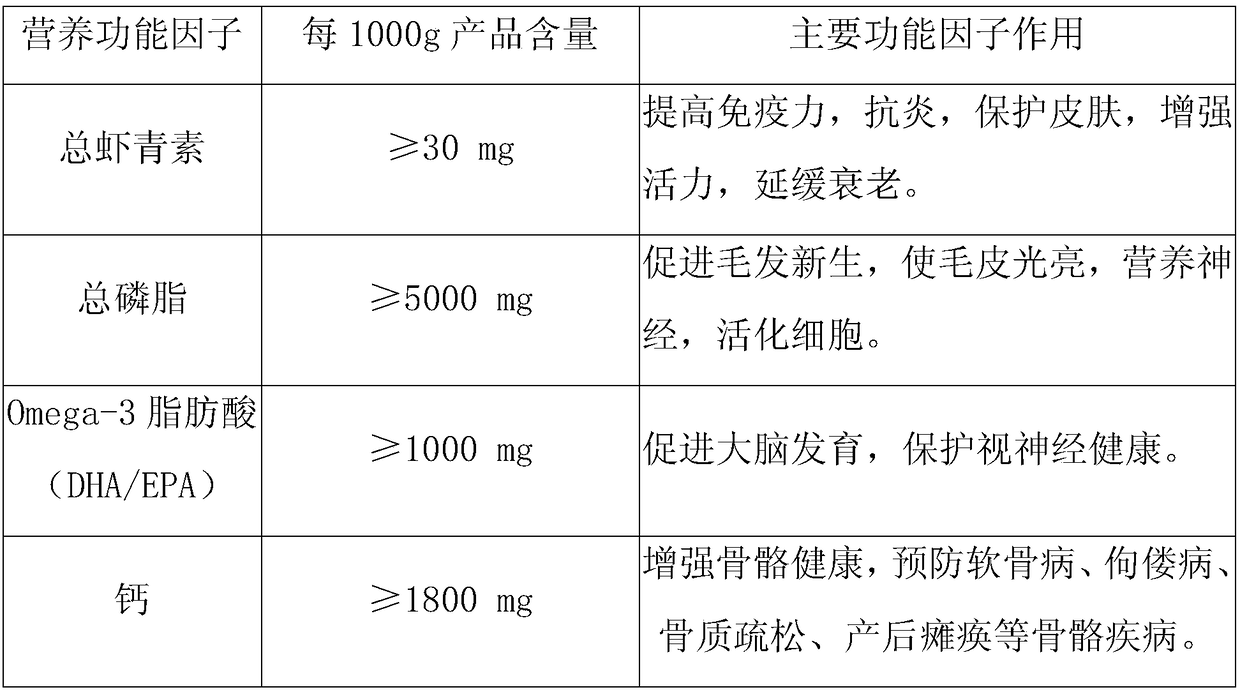

A technology of arctic sweet shrimp and nutritional paste, applied in the directions of additional food elements, applications, animal feed, etc., can solve the problems of low utilization rate and waste of resources, and achieve the effects of natural raw materials, health protection, and brain development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Take 100kg of arctic sweet shrimp processing by-product raw materials, chop and crush them with a chopping machine, and then process the crushed raw materials through a colloid mill to form a fine muddy sample, and then heat treatment at 90°C for 30 minutes .

[0026] (2) After heating in step (1), cool the raw materials to 40°C, then add neutral protease and neutral lipase to the system at the same time for enzymolysis, the enzymolysis temperature is 40°C, the process is stirred intermittently, and the enzymolysis time 2h, the amount of protease added was 500U / g, and the amount of lipase added was 100U / g.

[0027] (3) Preparation of water-based base material

[0028] Take 100 parts of water, 5 parts of gelatin, 15 parts of peptone, 10 parts of hydrolyzed animal protein, 10 parts of milk powder, 10 parts of glucose, 5 parts of maltose, 10 parts of white granulated sugar, and 0.5 parts of vitamins. The above-mentioned samples were weighed in proportion, and after b...

Embodiment 2

[0037] (1) Take 100kg of arctic sweet shrimp processing by-product raw materials, use a grinder to crush them, and then process the crushed raw materials through a colloid mill to form a fine muddy sample, and then heat treatment at 100°C for 10 minutes .

[0038] (2) After heating in step (1), cool the raw materials to 35°C, then add papain and pancrelipase to the system at the same time for enzymolysis, the enzymolysis temperature is 44°C, stir intermittently during the process, and the enzymolysis time is 1.5h , wherein the added amount of protease is 800U / g, and the added amount of lipase is 1200U / g.

[0039] (3) Preparation of water-based base material

[0040] Take 100 parts of water, 7 parts of pectin, 20 parts of peptone, 6 parts of chicken hydrolyzed protein, 10 parts of milk powder, 15 parts of glucose, 10 parts of maltose, 15 parts of white sugar, and 0.8 parts of vitamins. The above-mentioned samples were weighed in proportion, and after being completely hydrated...

Embodiment 3

[0049] (1) Take 1 kg of arctic sweet shrimp processing by-product raw materials, use a chopping machine to chop and crush the crushed raw materials, and then process the crushed raw materials through a colloid mill to form a fine muddy sample, and then heat treatment at 85°C for 40 minutes .

[0050] (2) After heating in step (1), cool the raw materials to 45°C, then add trypsin and alkaline lipase to the system at the same time for enzymolysis, the enzymolysis temperature is 40°C, stir intermittently during the process, and the enzymolysis time is 3h , wherein the added amount of protease is 300U / g, and the added amount of lipase is 80U / g.

[0051] (3) Preparation of water-based base material

[0052] Take 100 parts of water, 5 parts of carrageenan, 12 parts of peptone, 20 parts of bovine hydrolyzed protein, 13 parts of milk powder, 15 parts of glucose, 7 parts of maltose, 13 parts of white sugar, and 1 part of vitamins. The above-mentioned samples were weighed in proportio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com