Copper-based catalyst for dimethyl oxalate hydrogenation as well as preparation method and application of copper-based catalyst

A copper-based catalyst, dimethyl oxalate technology, applied in the preparation of hydroxyl compounds, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low ethylene glycol selectivity and catalyst reaction temperature. and high pressure, catalyst deactivation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

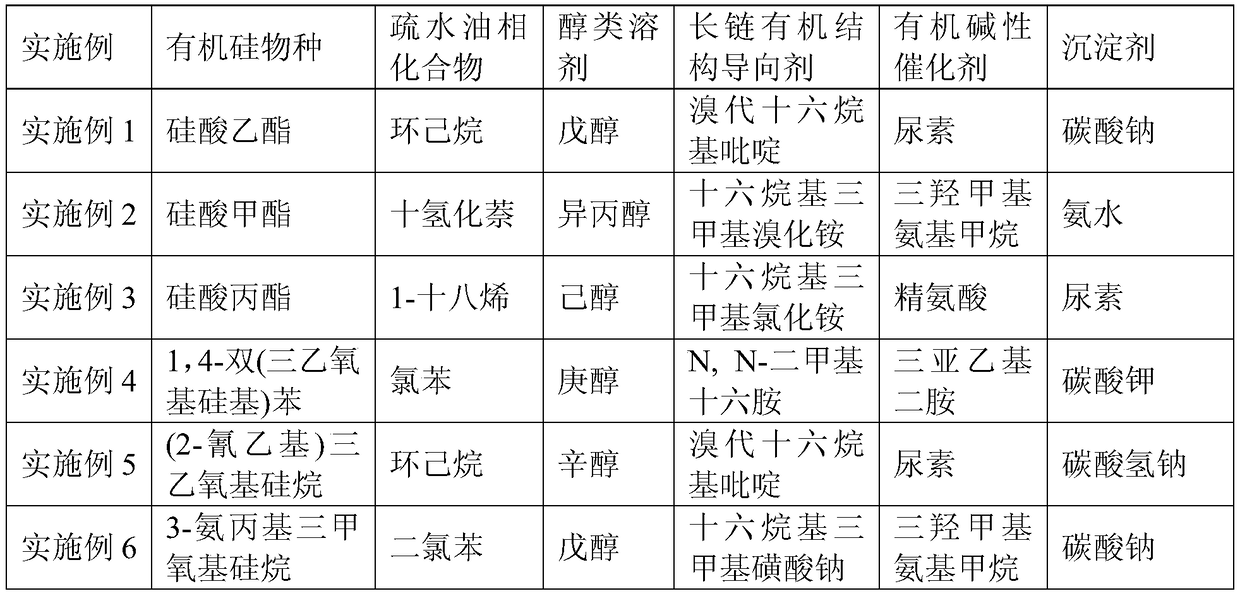

[0035] A copper-based catalyst for the hydrogenation of dimethyl oxalate is prepared by the following method:

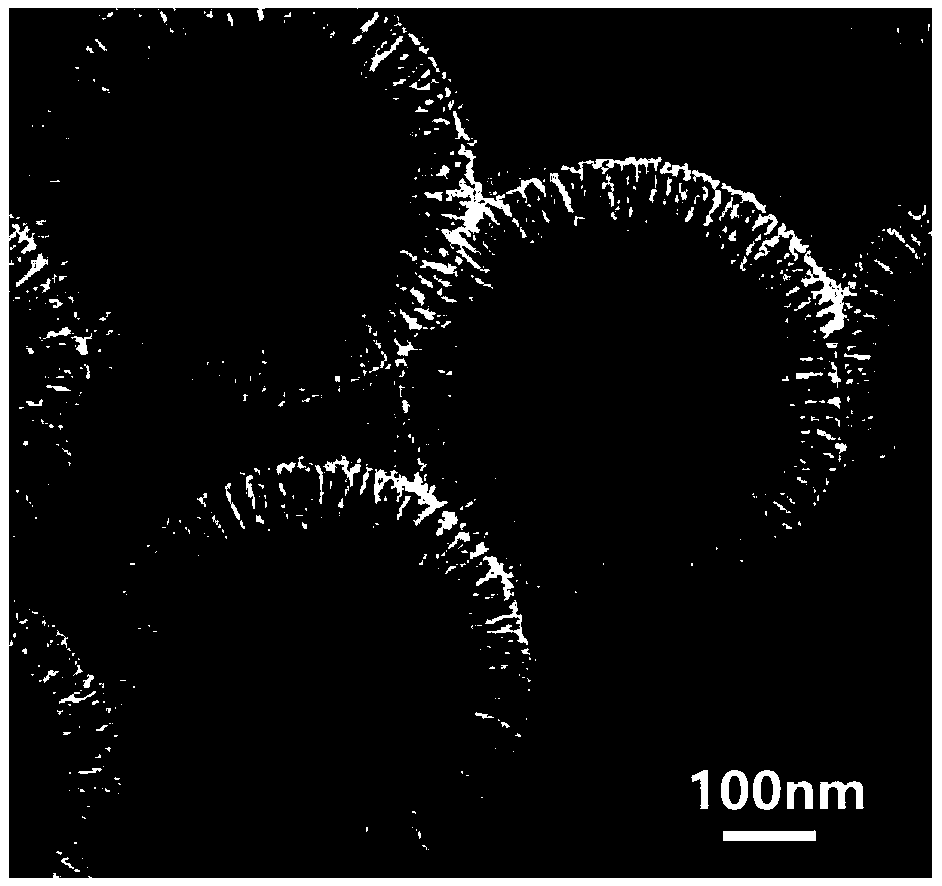

[0036] (1) Preparation of mesoporous silica nanospheres with central radial channels:

[0037] ① Fully dissolve 20.0g ethyl silicate (TEOS) in 187.20g cyclohexane and 9.84g pentanol solution;

[0038] ②Stir 8.0g of cetylpyridinium bromide (CTPB) and 4.8g of urea in 240ml of water evenly, then add to the solution of ①, stir the mixed solution for 30 minutes at room temperature, and then place it in a Teflon sealed reaction In the container, heat the reaction at 120°C for 4 hours;

[0039] ③After the reaction is completed, take out the reaction mixture in ② to quench, then centrifuge, wash with distilled water until the pH value is close to neutral, dry at 105°C for 12 hours, and then increase the temperature at a rate of 2°C / min from room temperature to 550°C for roasting After 6 hours, mesoporous silica nanospheres (DMSNs) with central radial channels were obtained...

Embodiment 2

[0043] A copper-based catalyst for the hydrogenation of dimethyl oxalate is prepared by the following method:

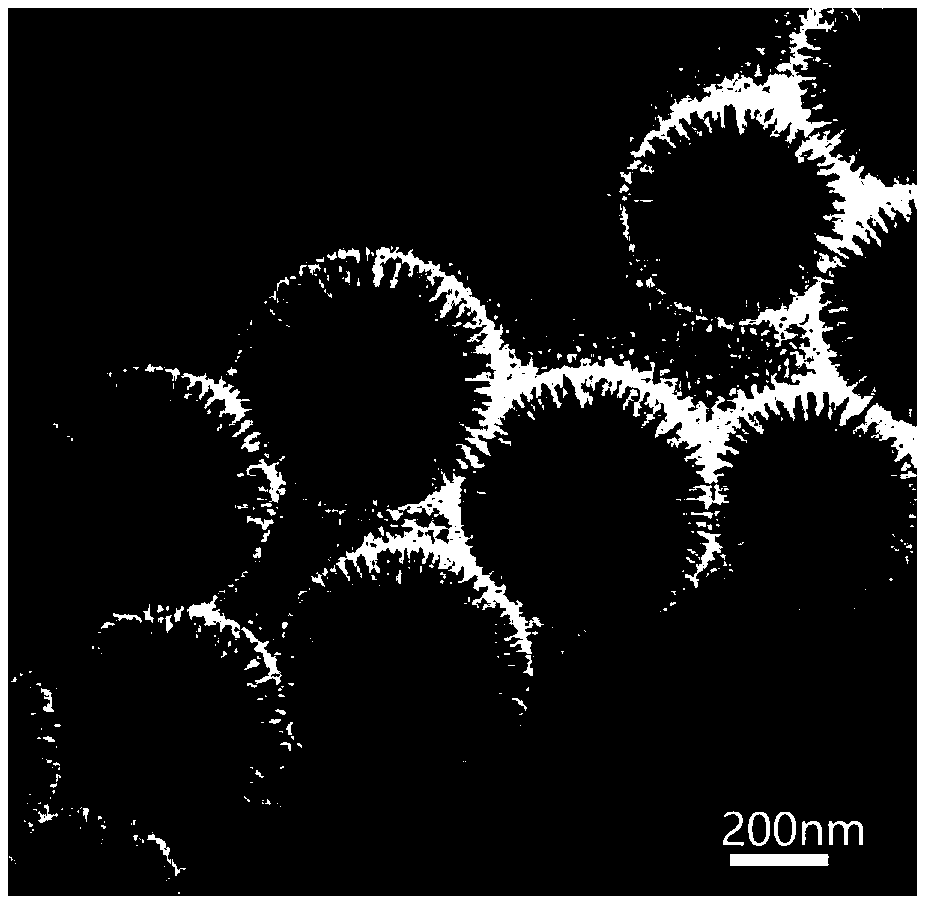

[0044] (1) Preparation of mesoporous silica nanospheres with central radial channels:

[0045] ①Dissolve 20g of methyl silicate (TMOS) in 430.50g of decalin and 11.05g of isopropanol.

[0046] ②Stir 14.37g of cetyltrimethylammonium bromide (CTAB) and 14.32g of trishydroxymethylaminomethane in 236.50ml of water and then add to the solution of ①. Stir the mixed solution for 30 minutes at room temperature, then Place it in a Teflon sealed reactor and heat it at 115°C for 6 hours;

[0047] ③After the reaction is completed, take out the reaction mixture in 2), quench it, and perform centrifugation, wash with distilled water until the pH value is close to neutral, dry at 105°C for 12 hours, and then increase the temperature at a rate of 1°C / min from room temperature to 550°C Calcined for 4 hours to obtain mesoporous silica nanospheres (DMSNs) with central radial channels...

Embodiment 3

[0051] A copper-based catalyst for the hydrogenation of dimethyl oxalate is prepared by the following method:

[0052] (1) Preparation of mesoporous silica nanospheres with central radial channels:

[0053] ①Dissolve 20g of propyl silicate in 301.72g of 1-octadecene and 6.96g of hexanol solution;

[0054] ②Stir 4.84g of cetyltrimethylammonium chloride (CTAC) and 8.85g of lysine in 204ml of water, then add to the solution of ①, stir the mixed solution for 30 minutes at room temperature, and then place it in In a Teflon sealed reactor, heat the reaction at 120°C for 6 hours;

[0055] ③ After the reaction is completed, take out the reaction mixture in ② to quench, and perform centrifugation, wash with distilled water until the pH value is close to neutral, dry at 105°C for 12 hours, and then increase the temperature at a rate of 5°C / min from room temperature to 550°C for roasting After 4 hours, mesoporous silica nanospheres (DMSNs) with central radial channels were obtained.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com