Method for efficiently preparing high-quality molybdenum disulfide nano-wires

A molybdenum disulfide and nanowire technology, applied in the field of nanomaterials, can solve the problems of multiple impurities and poor quality of molybdenum disulfide nanowires, and achieve the effect of expanding the selection range and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

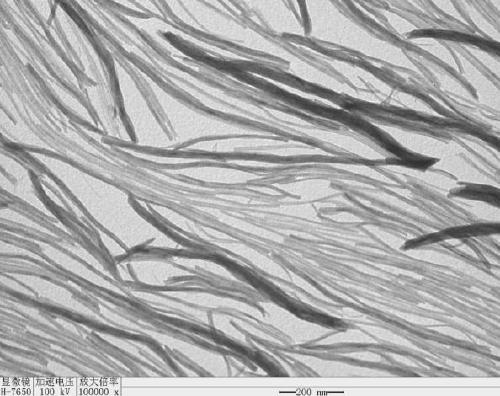

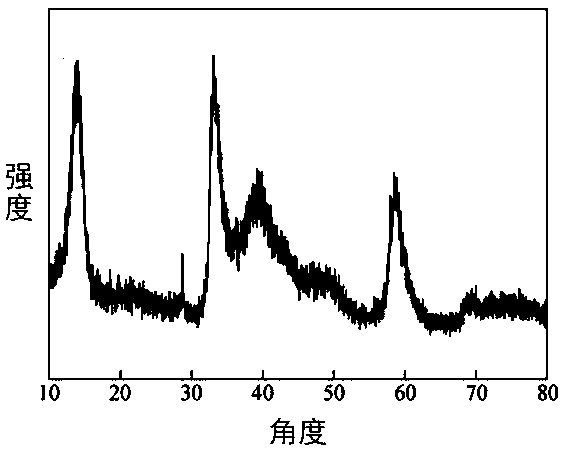

Embodiment 1

[0029] Add the ethylenediamine solution with a concentration of 0.03mg / mL into 50mL of cetyltrimethylammonium bromide aqueous solution, and carry out magnetic stirring to obtain solution A; Ammonium molybdate and thioacetamide were stirred and dispersed in deionized water to obtain solution B; after mixing solutions A and B evenly, slowly add 0.5 mL of hydrazine hydrate to the mixed solution with a pipette gun, and continue stirring (this Be sure to open the fume hood), then increase the temperature of the oil bath to 100°C and react for 12 hours. At the same time, adjust the speed of the shuttle magnet to 50rpm. After the reaction, the reaction solution was cooled to room temperature, and the product was centrifuged and washed.

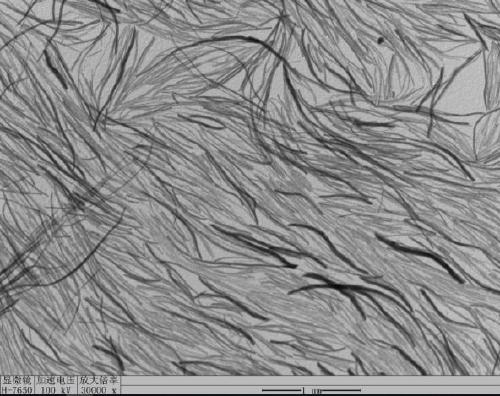

Embodiment 2

[0031] Add the ethylenediamine solution with a concentration of 0.03 mg / mL into 50 mL of cetyltrimethylammonium bromide aqueous solution, and carry out magnetic stirring to obtain solution A; Ammonium molybdate and thioacetamide were stirred and dispersed in deionized water to obtain solution B; after mixing solutions A and B evenly, slowly add 0.5 mL of hydrazine hydrate to the mixed solution with a pipette gun, and continue stirring (this Be sure to open the fume hood), then increase the temperature of the oil bath to 100°C and react for 20 hours, and at the same time, adjust the speed of the shuttle magnet to 50rpm. After the reaction, the reaction solution was cooled to room temperature, and the product was centrifuged and washed.

Embodiment 3

[0033] Add the ethylenediamine solution with a concentration of 0.03mg / mL into 50mL of octadecyltrimethylammonium bromide aqueous solution, and carry out magnetic stirring to obtain solution A; Ammonium molybdate and thioacetamide were stirred and dispersed in deionized water to obtain solution B; after mixing solutions A and B evenly, slowly add 0.5 mL of hydrazine hydrate to the mixed solution with a pipette gun, and continue stirring (this Be sure to open the fume hood), then increase the temperature of the oil bath to 100°C and react for 12 hours. At the same time, adjust the speed of the shuttle magnet to 50rpm. After the reaction, the reaction solution was cooled to room temperature, and the product was centrifuged and washed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com