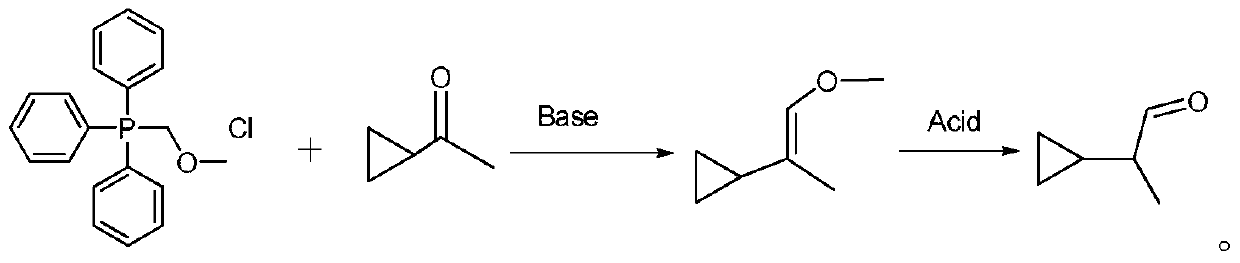

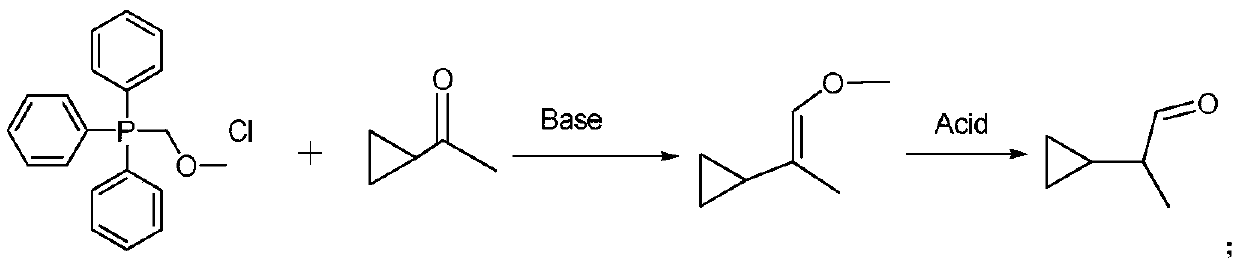

A kind of preparation method of 2-cyclopropyl propionaldehyde

A technology of cyclopropyl propanal and cyclopropyl methyl ketone, which is applied in the field of preparation of 2-cyclopropyl propanal, can solve the problems of high yield and few steps, achieve high yield, few by-products, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 317.93g (1.2mol) of triphenylphosphine, 251.56g (3.24mol) of methylal and 3.1g of methanol into a four-neck flask, add 118.94g (1.5mol) of acetyl chloride dropwise at room temperature, dropwise for 4 hours, dropwise After completion, the temperature was raised to 50° C. and refluxed for 4 hours; filtered, the filter cake was rinsed with 100 g of toluene, and the filter cake was dried to obtain 406.3 g of methoxymethyltriphenylphosphorous chloride, with a yield of 98.8%.

[0023] Add 41.59g (0.12mol) of methoxymethyltriphenylphosphorous chloride and 150g of tetrahydrofuran into a four-necked flask, cool down to 0°C, add 13.6g (0.12mol) of potassium tert-butoxide in batches, and then dropwise add Cyclopropyl methyl ketone 8.5g (0.1mol), dropwise time is 0.5h, dropwise temperature is 15°C, after the dropwise addition is completed, react at 25°C for 0.5h; remove 75g of tetrahydrofuran under normal pressure, add 58.4g of hydrochloric acid (wt15 %, 0.24mol), the temperatu...

Embodiment 2

[0025] Add 317.93g (1.2mol) of triphenylphosphine, 232.9g (3mol) of methylal and 3.8g of methanol into a four-neck flask, add 87.2g (1.1mol) of acetyl chloride dropwise at room temperature, dropwise for 3 hours, and end the dropwise addition Afterwards, the temperature was raised to 50° C. and refluxed for 3 hours; filtered, the filter cake was rinsed with 100 g of toluene, and the filter cake was dried to obtain 394 g of methoxymethyltriphenylphosphorous chloride, with a yield of 95.8%.

[0026] Add 69.3g (0.2mol) of methoxymethyltriphenylphosphonium chloride and 200g of tetrahydrofuran into a four-necked flask, cool down to -10°C, add 27.2g (0.24mol) of potassium tert-butoxide in batches, and drop Add 11.33g (0.133mol) of cyclopropyl methyl ketone, dropwise time is 1h, dropwise temperature is 20°C, after the dropwise addition is completed, react at 30°C for 2h; remove 150g THF under normal pressure, add 129.36g sulfuric acid (wt20% , 0.264mol), the temperature was raised to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com