Synthesis method of high-purity benzene sulfonyl chloride

A technology of benzenesulfonyl chloride and a synthesis method is applied in the field of synthesis of high-purity benzenesulfonyl chloride, and can solve the problems of low product purity, inability to provide high-purity benzenesulfonyl chloride in a production process, and not being ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

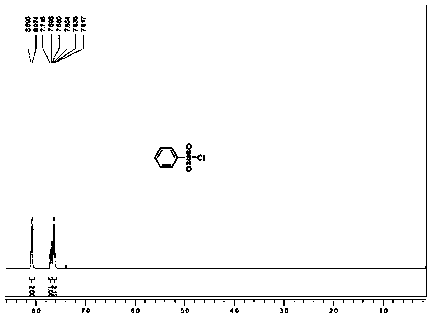

Image

Examples

Embodiment 1

[0025] Add 800 milliliters of water to 500 grams of benzenesulfonic acid, add dropwise 32% liquid caustic soda to pH~7.5, add 5 grams of activated carbon, heat and reflux for 30 minutes, and suction filter while it is hot; Clear, cool naturally to 15°C to crystallize, filter with suction, and dry in an oven at 125°C to constant weight.

[0026] Add 1 liter of toluene to the solid, add 800 grams of phosphorus pentachloride in batches under stirring, heat and reflux for 5 hours; cool, slowly pour the reaction solution onto crushed ice to extract the reaction, separate the liquids, and wash the organic phase once with water , dried over anhydrous sodium sulfate, concentrated to remove toluene, and distilled under reduced pressure to obtain 380 g of benzenesulfonyl chloride with a purity of 99.6%.

Embodiment 2

[0028] Add 500 grams of benzenesulfonic acid, 80 grams of magnesium oxide and 800 milliliters of water into the reaction flask, heat and reflux for 2 hours; cool to 90 ° C, add 5 grams of activated carbon, heat and reflux for 30 minutes, and suction filter while it is hot; concentrate the filtrate and add 600 Milliliter of ethanol, then heated to dissolve the liquid, cooled naturally to 15°C to crystallize, filtered with suction, and dried in an oven at 125°C to constant weight.

[0029] Cool 1 liter of N,N-dimethylformamide to -5°C, slowly add 560 g of thionyl chloride dropwise, stir for 30 minutes, then add the above dry solid in batches within 1 hour; raise the temperature to 25°C, Stir the reaction for 24 hours, slowly pour the reaction solution onto crushed ice to extract the reaction, extract with chloroform, combine the organic phases and wash with water, dry over anhydrous sodium sulfate, concentrate to remove toluene, and distill under reduced pressure to obtain 482 gr...

Embodiment 3

[0031] Add 500 grams of benzenesulfonic acid, 85 grams of lithium hydroxide and 800 milliliters of isopropanol into the reaction flask, heat and reflux for 2 hours; cool to 50°C, add 5 grams of activated carbon, heat and reflux for 30 minutes, and suction filter while hot; the filtrate is naturally Cool to 10°C to crystallize, filter with suction, and dry in an oven at 125°C to constant weight.

[0032] Add 1 liter of acetonitrile and 20 ml of N,N-dimethylformamide to the solid, add 650 g of phosphorus oxychloride dropwise under reflux, and continue heating to reflux for 5 hours; distill off the acetonitrile, add 1 liter of dichloromethane, Cool with ice water to control the temperature below 20°C, add 600 g of ice water dropwise to extract the reaction, separate the liquid, wash the organic phase once with water, dry with anhydrous sodium sulfate, concentrate to remove toluene, and distill under reduced pressure to obtain 260 g of benzenesulfonyl chloride with a purity of 99.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com