Electromagnetic shielding wall plate

An electromagnetic shielding and wallboard technology, applied in conductive coatings, conjugated diene coatings, polyurea/polyurethane coatings, etc., can solve the problem of low electromagnetic shielding performance of wallboards, improve shielding efficiency and increase coating life. , the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

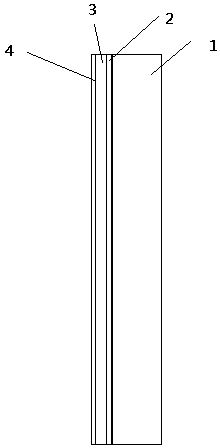

[0014] An electromagnetic shielding wallboard and a manufacturing method thereof. The electromagnetic shielding wallboard includes a concrete prefabricated substrate, a nickel alloy hole mesh sheet is adhered to one side, and the exterior of the nickel alloy hole mesh sheet is a plastering mortar layer, and the plastering mortar layer is externally coated Covered with shielding rubber coating,

[0015] The manufacturing method of the electromagnetic shielding wallboard includes the following steps:

[0016] First, 73 parts of polyurethane resin, 12 parts of styrene-acrylic emulsion, 21 parts of butadiene rubber, 80 parts of ethyl acetate, and 25 parts of xylene are put into the agitator and heated to 35°C for mixing according to parts by weight. The stirring speed is 300-400rpm. After uniformity, add 10-15 parts of barite powder, 14 parts of white carbon black powder and 20 parts of nickel powder, cool down to 30°C and keep it for 20 minutes, then add 5 parts of dibutyltin dil...

Embodiment 2

[0020] An electromagnetic shielding wallboard and a manufacturing method thereof. The electromagnetic shielding wallboard includes a concrete prefabricated substrate, a nickel alloy hole mesh sheet is adhered to one side, and the exterior of the nickel alloy hole mesh sheet is a plastering mortar layer, and the plastering mortar layer is externally coated Covered with shielding rubber coating,

[0021] The manufacturing method of the electromagnetic shielding wallboard includes the following steps:

[0022] First, put 73 parts of polyurethane resin, 18 parts of styrene-acrylic emulsion, 25 parts of butadiene rubber, 90 parts of ethyl acetate, and 30 parts of xylene into the agitator to heat up to 35°C for mixing according to parts by weight. The stirring speed is 300-400rpm. After uniformity, add 11 parts of barite powder, 14 parts of white carbon black powder and 29 parts of nickel powder, cool down to 30°C and keep it warm for 20 minutes, then add 4 parts of dibutyltin dilau...

Embodiment 3

[0026] An electromagnetic shielding wallboard and a manufacturing method thereof. The electromagnetic shielding wallboard includes a concrete prefabricated substrate, a nickel alloy hole mesh sheet is adhered to one side, and the exterior of the nickel alloy hole mesh sheet is a plastering mortar layer, and the plastering mortar layer is externally coated Covered with shielding rubber coating,

[0027] The manufacturing method of the electromagnetic shielding wallboard includes the following steps:

[0028] First, 77 parts of polyurethane resin, 18 parts of styrene-acrylic emulsion, 22 parts of butadiene rubber, 80 parts of ethyl acetate, and 35 parts of xylene are put into the agitator and heated to 35°C for mixing according to parts by weight. The stirring speed is 300-400rpm. After uniformity, add 11 parts of barite powder, 12 parts of white carbon black powder and 26 parts of nickel powder, lower the temperature to 30°C and keep it for 20 minutes, then add 5 parts of dibut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com