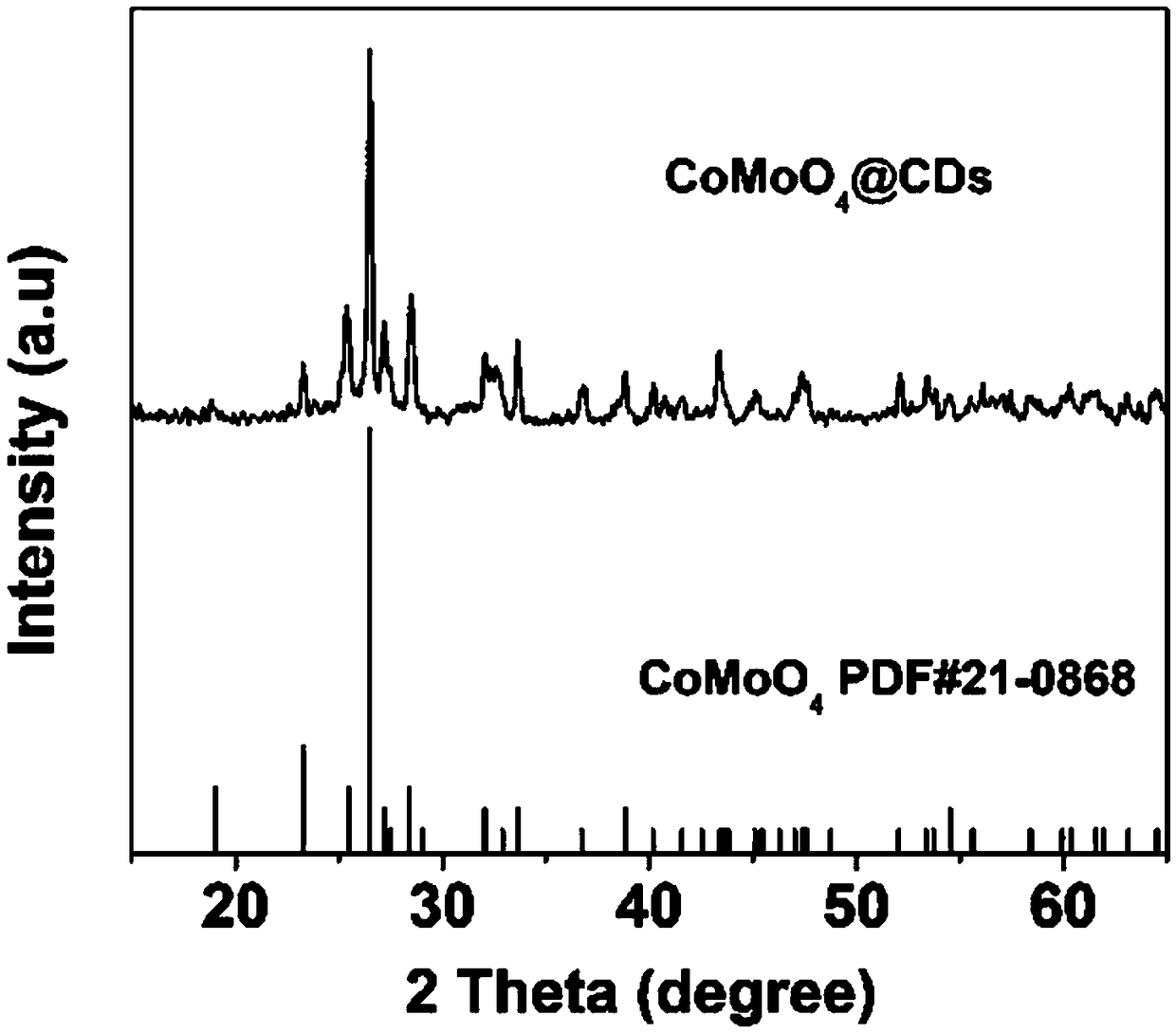

Cobalt molybdate composite carbon dot lithium ion battery positive electrode material and preparation method thereof

A lithium-ion battery and anode material technology, which is applied in the field of cobalt molybdate composite carbon-dot lithium-ion battery anode materials and its preparation, can solve problems such as volume expansion, capacity attenuation, and cycle life reduction, and achieve process controllability and increase ratio Capacity and energy density, high repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1), adding performic acid as an oxide to coal tar pitch and centrifuging for 24 hours to take the supernatant, which is a carbon dot solution using performic acid as a solvent;

[0025] 2), get 0.35g analytically pure ammonium molybdate ((NH 4 )Mo 7 o 24 4H 2 O) Put it in a mortar, then add 0.45 mg cobalt chloride hexahydrate (CoCl 2 ·6H 2 0) Grinding, fully grinding for half an hour; putting the ground mixture into a crucible for sintering in a muffle furnace; heating up to 120°C at a heating rate of 5°C / min, and keeping it warm for one hour; then heating at a heating rate of 1°C / min Speed up to 450°C and keep warm for two hours;

[0026] 3) Naturally cool to room temperature, filter the prepared product with water and ethanol using filter paper with a pore size of 0.224 μm, wash it 3-6 times, and put it in a vacuum drying oven at 70° C. for 24 hours;

[0027] 4) Take the dried product and add it to 30ml of deionized water, mix it well, put it into a polytetraf...

Embodiment 2

[0033] 1), adding performic acid as an oxide to coal tar pitch and centrifuging for 24 hours to take the supernatant, which is a carbon dot solution using performic acid as a solvent;

[0034] 2), get 0.15g analytically pure ammonium molybdate ((NH 4 )Mo 7 o 24 4H 2 O) Put it in a mortar and add 0.35mg of cobalt chloride hexahydrate (CoCl 2 ·6H 20) Grinding, fully grinding for half an hour; putting the ground mixture into a crucible for sintering in a muffle furnace; raising the temperature to 100° C. at a heating rate of 10° C. / min, and keeping it warm for 3 hours; Speed up to 350°C and keep warm for 3 hours;

[0035] 3), naturally cool to room temperature, filter the obtained product with water and ethanol and wash 3-6 times, put it in a vacuum drying oven at 60°C for 24 hours;

[0036] 4) Take the dried product and add it to 5ml of carbon dot solution, mix well, put it into a polytetrafluoroethylene lining, and react with hydrothermal reaction at 150°C for 10h;

[...

Embodiment 3

[0039] 1), adding performic acid as an oxide to coal tar pitch and centrifuging for 24 hours to take the supernatant, which is a carbon dot solution using performic acid as a solvent;

[0040] 2), get 0.65g analytically pure ammonium molybdate ((NH 4 )Mo 7 o 24 4H 2 O) Put it in a mortar and add 0.85mg of cobalt chloride hexahydrate (CoCl 2 ·6H 2 0) Grinding, fully grinding for half an hour; putting the ground mixture into a crucible and sintering in a muffle furnace; raising the temperature to 80°C at a heating rate of 8°C / min, and keeping it warm for 2 hours; Speed up to 300°C and keep warm for 2 hours;

[0041] 3) Naturally cool to room temperature, filter the obtained product with water and ethanol and wash 3-6 times, put it in a vacuum drying oven at 80°C for 24 hours;

[0042] 4) Take the dried product and add it to 30ml of carbon dot solution, mix well, put it into a polytetrafluoroethylene lining, and conduct a hydrothermal reaction at 180°C for 6h;

[0043] 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com