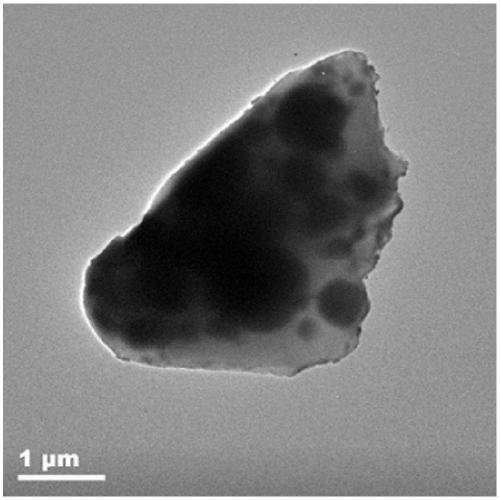

Crystalline silicon dioxide wrapped gamma-Ce2S3 red pigment and preparation method thereof

A silicon dioxide and crystalline technology, applied in the field of inorganic pigments, can solve the problems of poor compactness, incomplete wrapping, and easy damage of the wrapping layer, achieve excellent acid corrosion resistance and high temperature oxidation resistance, improve wrapping efficiency, and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

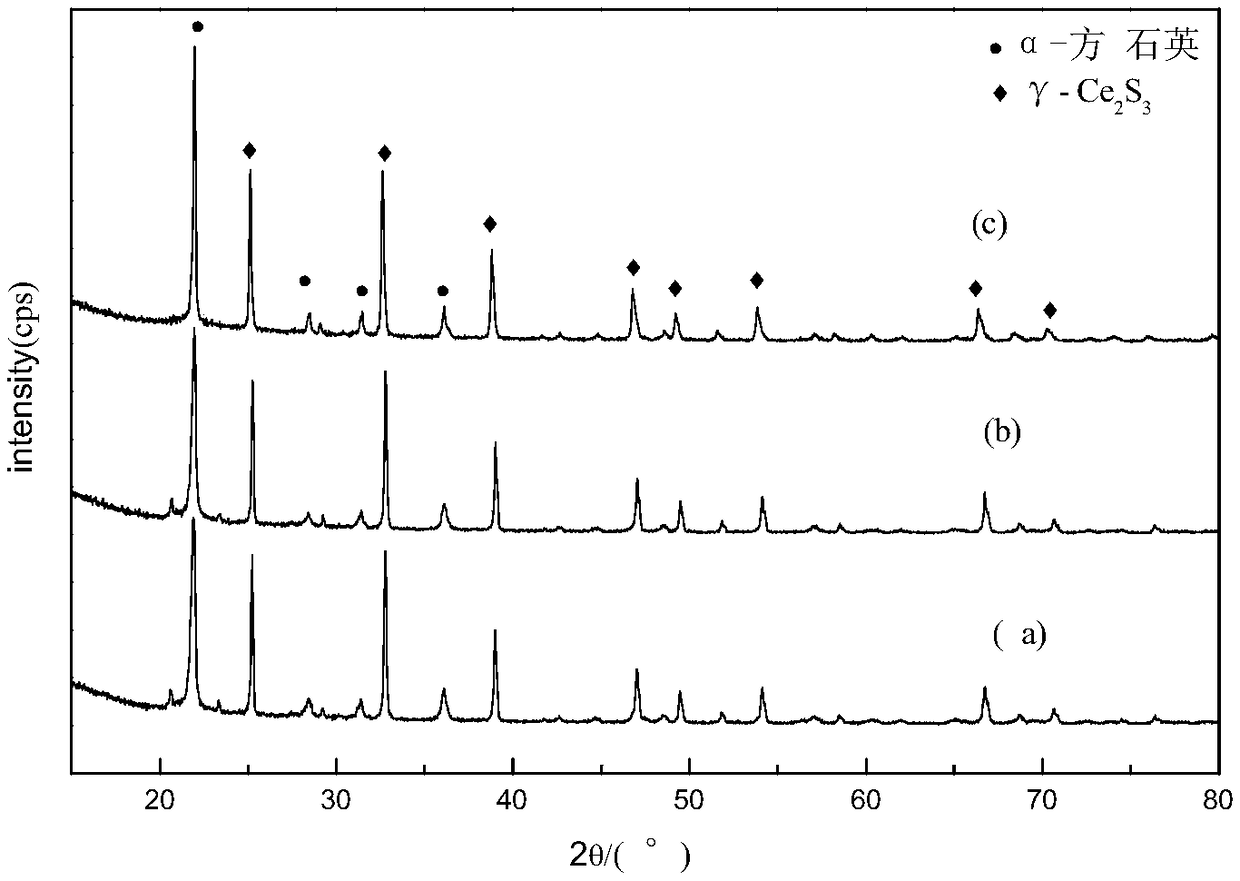

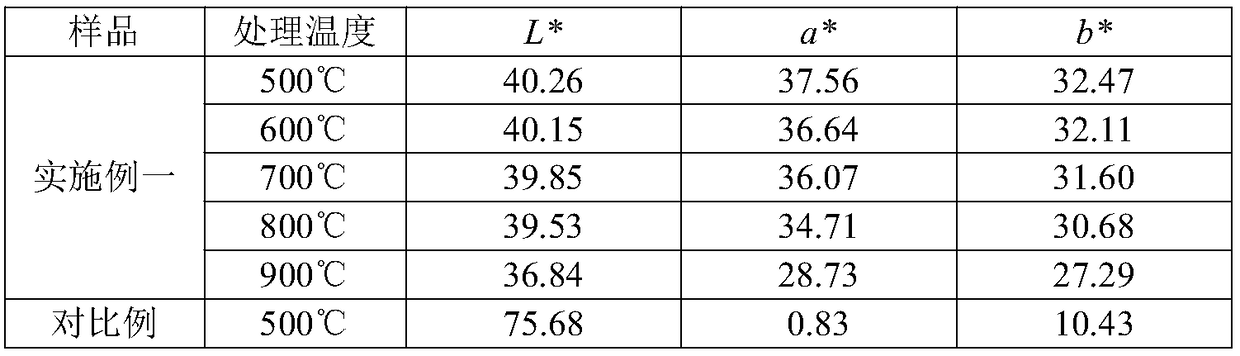

[0029] In this embodiment, a crystalline silica-encapsulated γ~Ce 2 S 3 The preparation method of red pigment, its step is as follows:

[0030] (1) Preparation of raw material solution

[0031] Cerium source solution: according to molar ratio Ce 3+ : HNO 3 :Urea:Na + =1:4:8:0.2, Ce(NO 3 ) 3 ·6H 2 O, concentration is that nitric acid, urea, sodium nitrate of 0.1mol / L are dissolved in the alcohol-water mixture that is made up of 10mL deionized water and 15mL dehydrated alcohol, obtain doping with Na + The cerium source solution;

[0032] Silicon source solution: Dissolve tetraethyl orthosilicate in absolute ethanol according to the volume ratio of tetraethyl orthosilicate: dehydrated alcohol=1:2 to obtain a silicon source solution;

[0033] (2) According to the molar ratio Si 4+ : Ce 3+ =5:1, pour the above silicon source solution into doped Na + Stir and mix in the cerium source solution evenly, add nitric acid to adjust the pH value of the mixed solution to 1, and ...

Embodiment 2

[0038] In this embodiment, a crystalline silica-encapsulated γ~Ce 2 S 3 The preparation method of red pigment, its step is as follows:

[0039] (1) Preparation of Li + Doped precursor powder

[0040] (1-1) Preparation of raw material solution

[0041] Cerium source solution: according to molar ratio Ce 3+ : HNO 3 :Urea:Li + =1:6:7:0.1, Ce(NO 3 ) 3 ·6H 2 O, concentration is that nitric acid, urea, lithium nitrate of 0.1mol / L are dissolved in the alcohol-water mixture that is made up of 10mL deionized water and 15mL dehydrated alcohol, obtain doping with Li + The cerium source solution;

[0042] Silicon source solution: Dissolve tetraethyl orthosilicate in absolute ethanol to obtain a silicon source solution according to the volume ratio tetraethyl orthosilicate: dehydrated alcohol=1:2.5;

[0043] (1-2) According to the molar ratio Si 4+ : Ce 3+ = 6:1, the above silicon source solution is poured into doped with Li + Stir and mix evenly in the cerium source solution...

Embodiment 3

[0047] In this embodiment, a crystalline silica-encapsulated γ~Ce 2 S 3 The preparation method of red pigment, its step is as follows:

[0048] (1) Preparation of Li + 、Na + Co-doped precursor powder

[0049] (1-1) Preparation of raw material solution

[0050] Cerium source solution: according to molar ratio Ce 3+ : HNO 3 :Urea:Li + :Na + =1:5:8:0.05:0.05, Ce(NO 3 ) 3 ·6H 2 O, concentration is that the nitric acid of 0.1mol / L, urea, lithium nitrate, sodium nitrate are dissolved in the alcohol-water mixture that is made up of 10mL deionized water and 15mL dehydrated alcohol, obtain Li + 、Na + Co-doped cerium source solution;

[0051] Silicon source solution: Dissolve tetraethyl orthosilicate in absolute ethanol according to the volume ratio of tetraethyl orthosilicate: dehydrated alcohol=1:3 to obtain a silicon source solution;

[0052] (1-2) According to the molar ratio Si 4+ : Ce 3+ =5.5:1, pour the above silicon source solution into Li + 、Na + Stir and mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com