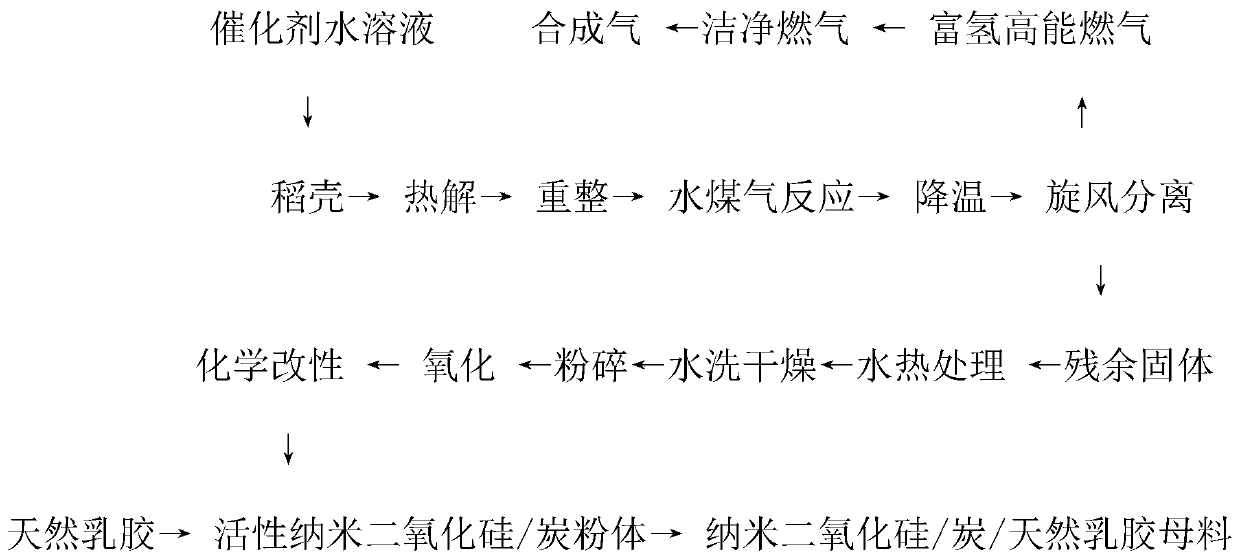

Method for co-producing nano-silica composite material with hydrogen-rich high-energy gas from biomass

A technology of nano-silica and composite materials, applied in the direction of silica, silicon oxide, combustible gas purification, etc., can solve the problems of high processing cost, high oxygen content of biomass, low H/C ratio, etc., to improve catalytic performance effect, promote tar carbonization, increase the effect of carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Step 1, configuration containing 5wt% NH 4 Cl, containing 2wt% CaCl 2 , the catalyst aqueous solution containing 3wt% KCl;

[0054] Step 2. Continuously add rice husks into the downdraft pyrolysis furnace, and at the same time, evenly spray the aqueous catalyst solution prepared in step 1 until the water content of the system is 47wt%, which is evenly distributed with rice husks; through the preheating zone at 200°C to 300°C Low-temperature dehydration, entering the pyrolysis section, where the rice husk is catalytically pyrolyzed at 800°C in a water vapor atmosphere; entering the tar conversion section, where the tar is catalytically reformed at 850°C in a water vapor atmosphere; finally entering the water gas reaction section, where the rice husk is Under steam atmosphere, catalytic pyrolysis at 900°C; continue to drop to the cooling section to cool down to 350°C-400°C, and use a cyclone separator to separate the mixed gas and remaining solids;

[0055] Step 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com