Landfill leachate composite water treatment agent and preparation method thereof

A domestic garbage and water treatment agent technology, applied in water/sewage treatment, oxidized water/sewage treatment, adsorption water/sewage treatment, etc., can solve the troublesome treatment process, the concentrate does not have biodegradability, increase the concentrate, etc. problem, to achieve the effect of improving flocculation effect, enhancing inhibition and killing effect, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

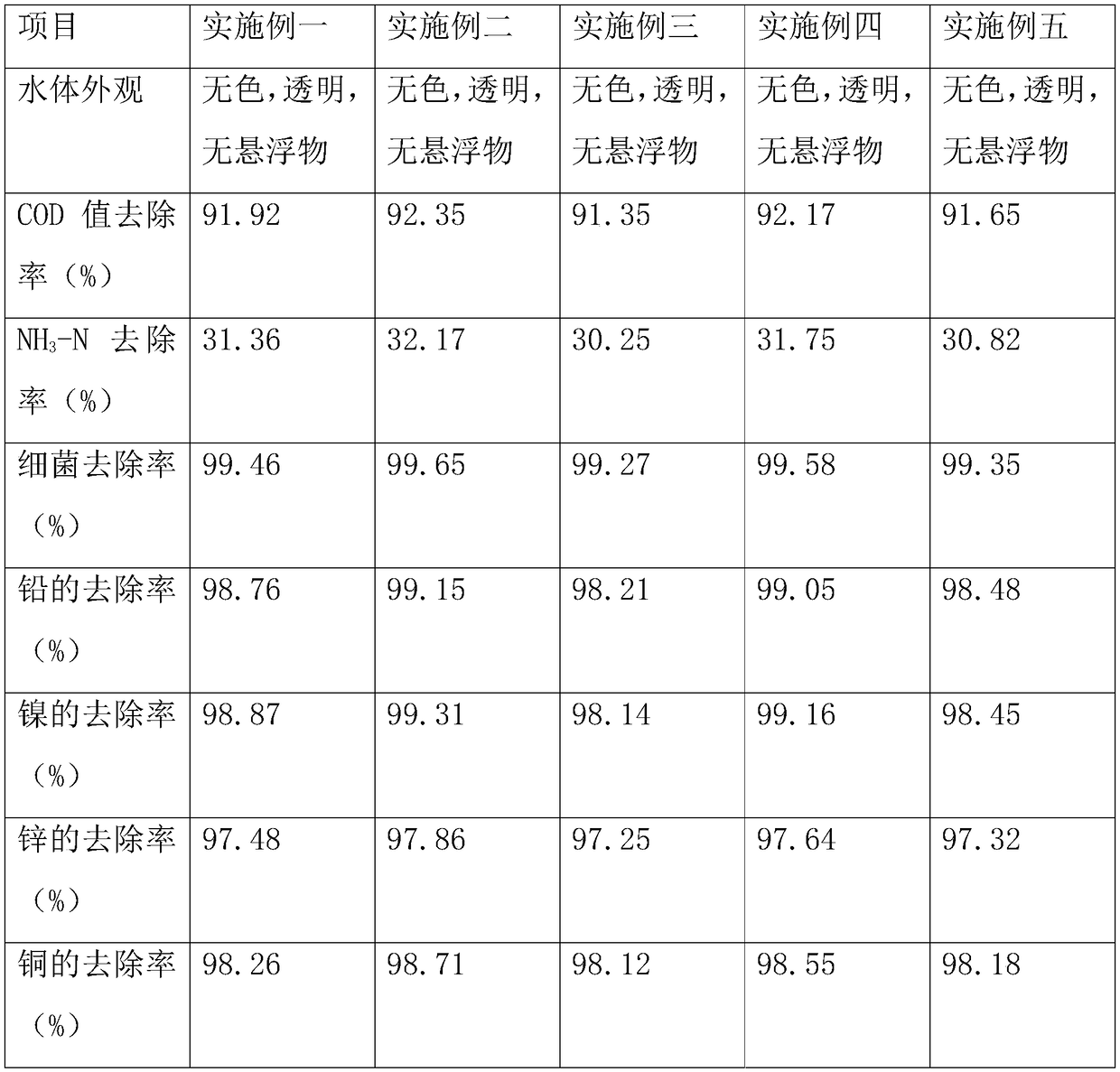

Examples

Embodiment 1

[0024] The composite water treatment agent for domestic waste leachate provided in this embodiment includes the following raw material components in parts by weight: 45 parts of polyacrylamide, 35 parts of polyaluminum sulfate, 35 parts of sodium polyacrylate, 28 parts of chitosan, Potassium ferrate 25 parts, expanded graphite 28 parts, pyrophyllite 28 parts, medical stone 28 parts, fly ash 28 parts, modified palm bark 35 parts, coconut shell activated carbon 35 parts, Moringa bark powder 20 parts.

[0025] The method for preparing the composite water treatment agent for the domestic waste leachate provided by the present embodiment comprises the following steps:

[0026] A. After mixing expanded graphite, pyrophyllite, medical stone, fly ash, modified palm skin, coconut shell activated carbon and Moringa bark powder, grind them into fine powder to obtain mixture I;

[0027] B. After soaking the mixture I with deionized water, add polyacrylamide, polyaluminum sulfate, sodium p...

Embodiment 2

[0036] The composite water treatment agent for domestic waste leachate provided in this embodiment includes the following raw material components in parts by weight: 50 parts of polyacrylamide, 40 parts of polyaluminum sulfate, 40 parts of sodium polyacrylate, 30 parts of chitosan, Potassium ferrate 26 parts, expanded graphite 30 parts, pyrophyllite 30 parts, medical stone 30 parts, fly ash 30 parts, modified palm bark 36 parts, coconut shell activated carbon 36 parts, Moringa bark powder 22 parts.

[0037] The method for preparing the composite water treatment agent for the domestic waste leachate provided by the present embodiment comprises the following steps:

[0038] A. After mixing expanded graphite, pyrophyllite, medical stone, fly ash, modified palm skin, coconut shell activated carbon and Moringa bark powder, grind them into fine powder to obtain mixture I;

[0039] B. After soaking the mixture I with deionized water, add polyacrylamide, polyaluminum sulfate, sodium p...

Embodiment 3

[0048] The composite water treatment agent for domestic waste leachate provided in this embodiment includes the following raw material components in parts by weight: 42 parts of polyacrylamide, 34 parts of polyaluminum sulfate, 34 parts of sodium polyacrylate, 25 parts of chitosan, Potassium ferrate 23 parts, expanded graphite 25 parts, pyrophyllite 25 parts, medical stone 25 parts, fly ash 25 parts, modified palm bark 33 parts, coconut shell activated carbon 33 parts, Moringa bark powder 18 parts.

[0049] The method for preparing the composite water treatment agent for the domestic waste leachate provided by the present embodiment comprises the following steps:

[0050] A. After mixing expanded graphite, pyrophyllite, medical stone, fly ash, modified palm skin, coconut shell activated carbon and Moringa bark powder, grind them into fine powder to obtain mixture I;

[0051] B. After soaking the mixture I with deionized water, add polyacrylamide, polyaluminum sulfate, sodium p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com