Environment-friendly PVC eraser with high finish and antibacterial function, and preparation process thereof

A preparation process, eraser technology, applied in the direction of eraser, printing, office supplies, etc., to achieve the effect of low wear, reduced wear loss, excellent hardness and puncture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

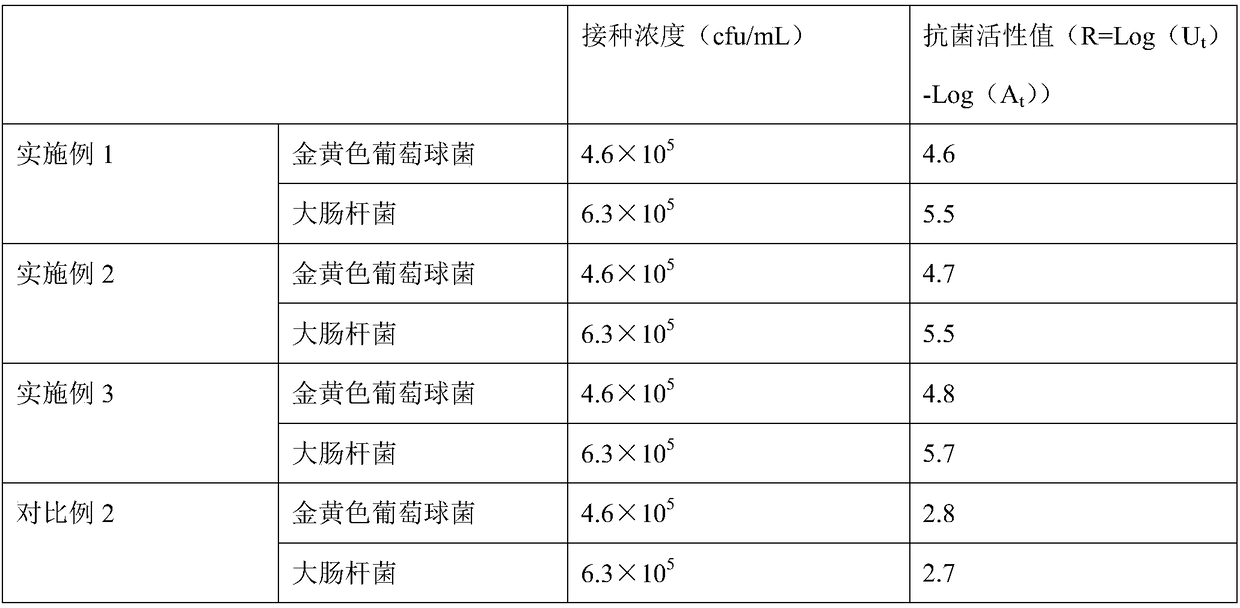

Embodiment 1

[0046] A kind of preparation technology of the environment-friendly PVC eraser with high light antibacterial function, concrete steps are as follows:

[0047] (1) dissolving polyvinyl alcohol with a degree of alcoholysis of 70 mol% in deionized water, then adding initiator and vinyl chloride monomer, uniformly dispersing and transferring to a polymerization kettle;

[0048] (2) Add a crosslinking agent and heat to 50°C for polymerization;

[0049] (3) When the conversion rate of vinyl chloride monomer reaches 42%, add silane coupling agent, hydroxypropyl methylcellulose, and sucrose polyester, and heat up to 75°C at a heating rate of 12°C / min for polymerization until chlorine The ethylene monomer conversion rate reaches 85%, the polymerization reaction is completed, the unreacted monomer is recovered, the obtained slurry is centrifuged and dried to obtain a modified polyvinyl chloride resin, which is used for future use;

[0050] (4) Add dioctyl terephthalate, paraffin oil, z...

Embodiment 2

[0066] A kind of preparation technology of the environment-friendly PVC eraser with high light antibacterial function, concrete steps are as follows:

[0067] (1) dissolving polyvinyl alcohol with a degree of alcoholysis of 72mol% in deionized water, then adding initiator and vinyl chloride monomer, uniformly dispersed and transferred to a polymerization kettle;

[0068] (2) Add a crosslinking agent and heat to 60°C for polymerization;

[0069] (3) When the conversion rate of vinyl chloride monomer reaches 46%, add silane coupling agent, hydroxypropyl methylcellulose, and sucrose polyester, and heat up to 75-80°C at a heating rate of 15°C / min for polymerization. Until the conversion rate of vinyl chloride monomer reaches 85%, the polymerization reaction is terminated, the unreacted monomer is recovered, and the obtained slurry is centrifuged and dried to obtain a modified polyvinyl chloride resin for future use;

[0070] (4) Add dioctyl terephthalate, paraffin oil, zinc stear...

Embodiment 3

[0086] A kind of preparation technology of the environment-friendly PVC eraser with high light antibacterial function, concrete steps are as follows:

[0087] (1) Dissolving polyvinyl alcohol with a degree of alcoholysis of 71mol% in deionized water, then adding initiator and vinyl chloride monomer, uniformly dispersed and transferred to a polymerization kettle;

[0088] (2) Add a crosslinking agent and heat to 55°C for polymerization;

[0089] (3) When the conversion rate of vinyl chloride monomer reaches 44%, add silane coupling agent, hydroxypropyl methylcellulose, and sucrose polyester, and heat up to 78°C at a heating rate of 13°C / min for polymerization until chlorine The ethylene monomer conversion rate reaches 85%, the polymerization reaction is completed, the unreacted monomer is recovered, the obtained slurry is centrifuged and dried to obtain a modified polyvinyl chloride resin, which is used for future use;

[0090] (4) Add dioctyl terephthalate, paraffin oil, zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com