Environment-friendly single liquid aqueous mixed coating and double liquid aqueous mixed coating

A water-based, coating technology, used in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor film hardness, material processing methods that limit the peeling of protective films, and difficult handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

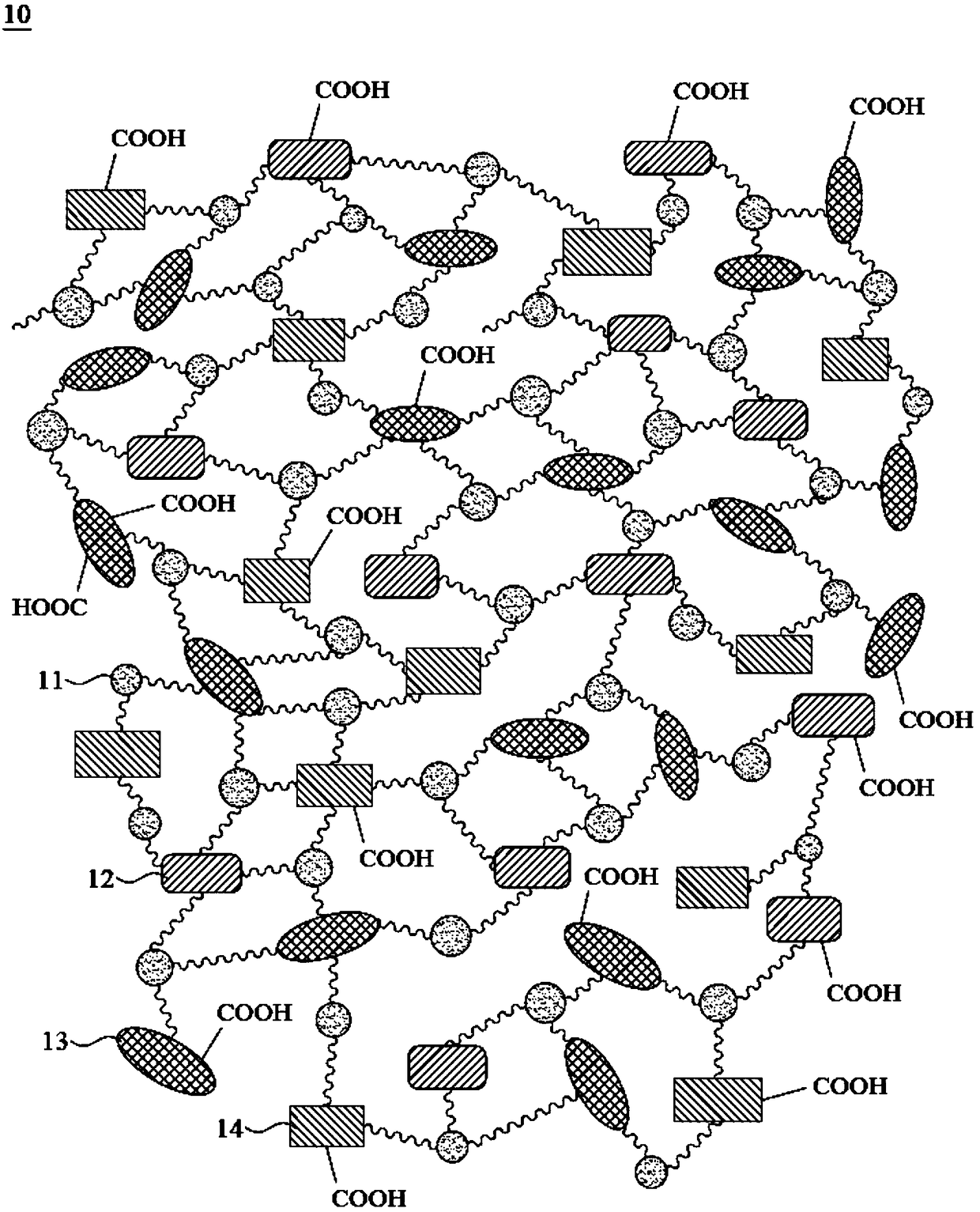

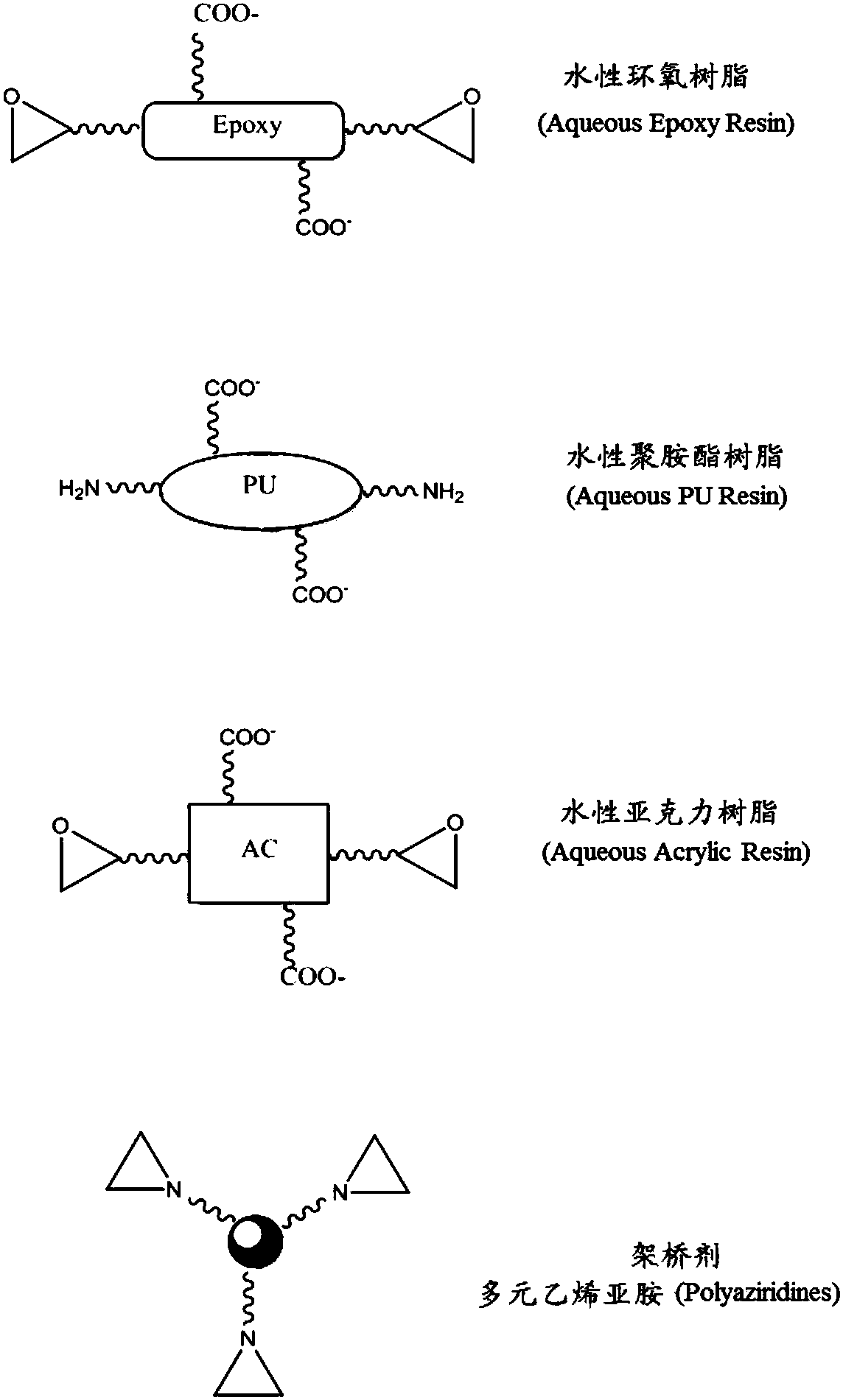

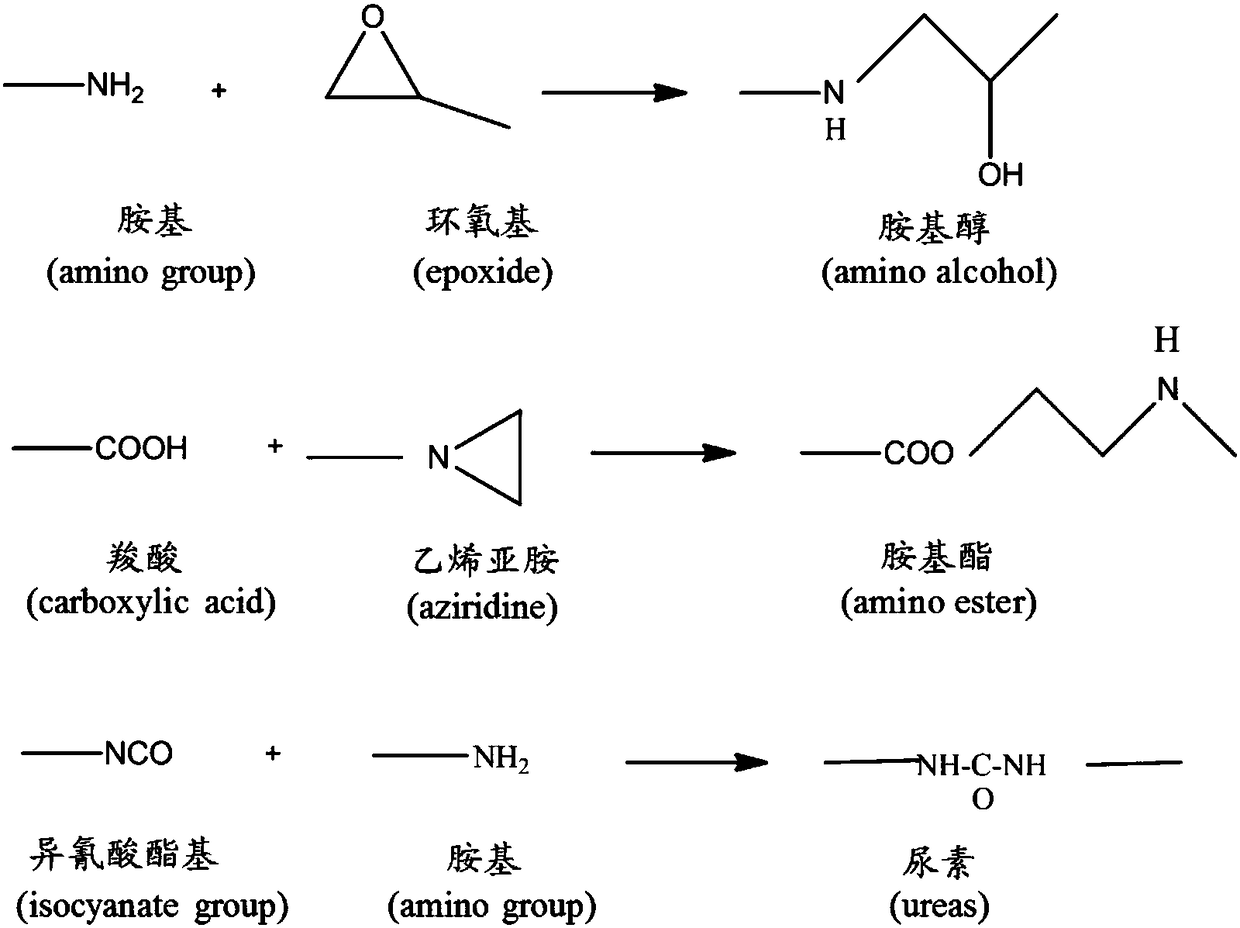

Method used

Image

Examples

Embodiment 1

[0109] Embodiment one: the water-based mixed coating of protecting plastic material

[0110] Select the hybrid resin of water-based PU resin dispersion (emulsion) (PU-1) and water-based acrylic resin (AC-2), PU-1 / AC-2=4 / 1, bridging agent, polyaziridines, PICASSIAN XL-706) accounts for 2.0% (2.0phr) of the solid content of the resin coating, and is prepared into a "single-component" water-based hybrid coating; sprayed on the surface of a clean polymethyl methacrylate (PMMA) transparent sheet, Then place it in a 50°C oven and dry it with hot air to form a transparent protective film with a thickness of about 35mm, a hardness of 1H pencil hardness, and an adhesion of 4-5B; after immersing the transparent sheet in a 60°C aqueous solution for 15 minutes, the coating film is smooth and automatic Shedding, no paint residue on PMMA surface.

Embodiment 2

[0111] Embodiment 2: Water-based hybrid paint for protecting aluminum materials:

[0112] Select the hybrid resin of water-based epoxy resin emulsion (EP-1), water-based PU resin dispersion (emulsion) (PU-1) and water-based acrylic resin (AC-1), EP-1 / PU-1 / AC-2= 2 / 3 / 1, bridging agent, polyaziridines (PICASSIAN XL-706) and polycarbodiimides (polycarbodiimides, PICASSIAN XL-701) are respectively 2.0% (2.0phr) of the solid content of the resin coating, Prepare a "single-component" water-based hybrid coating; before construction, add 20phr of fillers such as barium sulfate to increase the consistency of the water-based coating, increase the thickness of the coating film, and increase the wear resistance of the dry film. Before coating construction, use a mechanical mixer to stir the coating formula evenly, spray it on the cleaned aluminum surface, and then put it in a 90°C oven to dry with hot air to form a protective film with a thickness of about 50mm and a hardness of 2H pencil ...

Embodiment 3

[0113] Embodiment three: the water-based coating that protects stainless steel:

[0114] Select the mixed resin (EP-2 / PU-3 / AC-1= 2 / 3 / 1), when A agent; mixed bridging agent, polyaziridines (polyaziridines, PICASSIAN XL-706) and polyisocyanate (polyisocyanates, CORONATE AQ130) are 2.0% (2.0phr) of resin coating solid content when B agent, prepared into a "two-component" water-based hybrid coating; this two-component formulation (A / B agent) is mixed uniformly before spraying, and before construction, add barium sulfate and aluminum oxide 30phr (to increase the consistency of the water-based coating ), and increase the thickness of the coating film, as well as the abrasion resistance of the dry film. Before spraying, mix the paint formula evenly with three rollers, spray it on the surface of stainless steel, and then put it in an oven at 80°C to dry it with hot air to form a protective film with a thickness of about 55 mm and a hardness of 2-3H pencil hardness. (Baiger test) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com