An automatic bioreactor

A bioreactor and automatic technology, applied in the direction of photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem that the photobioreactor occupies a large area and cannot be used Issues such as energy supply and operation, reducing cultivation and purification costs, etc., to achieve the effect of enhancing light utilization and ornamental value, facilitating movement and fixing, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

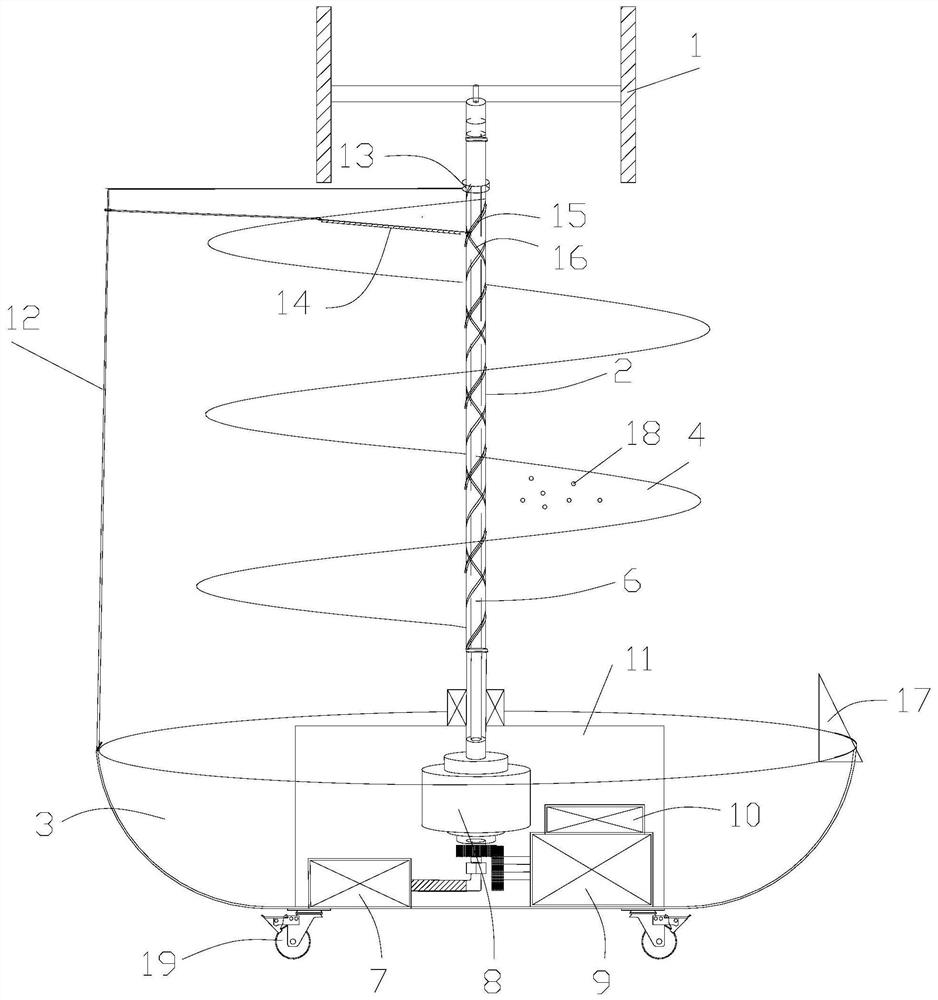

[0036] like figure 1 As shown, an automatic bioreactor of the present invention includes four major parts including a liquid collection tank 3, a main shaft 2, a light source device, and a vertical axis wind drive device 1.

[0037] Wherein, the liquid collecting tank 3 has a light-reflecting layer on its inner wall, which is used to contain the culture solution for cultivating microalgae. The sump 3 is "bowl-shaped", the reflective layer is a total reflection mirror film or tinfoil, and the side wall of the sump 3 is inclined; the bottom of the sump 3 is provided with universal wheels 19 for walking. The "bowl-shaped" side wall is inclined and can reflect the light in the environment to the three-dimensional spiral culture unit 4 through the total reflection side wall for the growth of microalgae; the bottom surface is provided with universal w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com