Method for preparing three-dimensional graphene/ foamed nickel composite material by taking loofah sponge as raw material

A technology of composite materials and loofah, which is applied in the field of graphene material synthesis, achieves the effect of simple method, less over-reliance and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

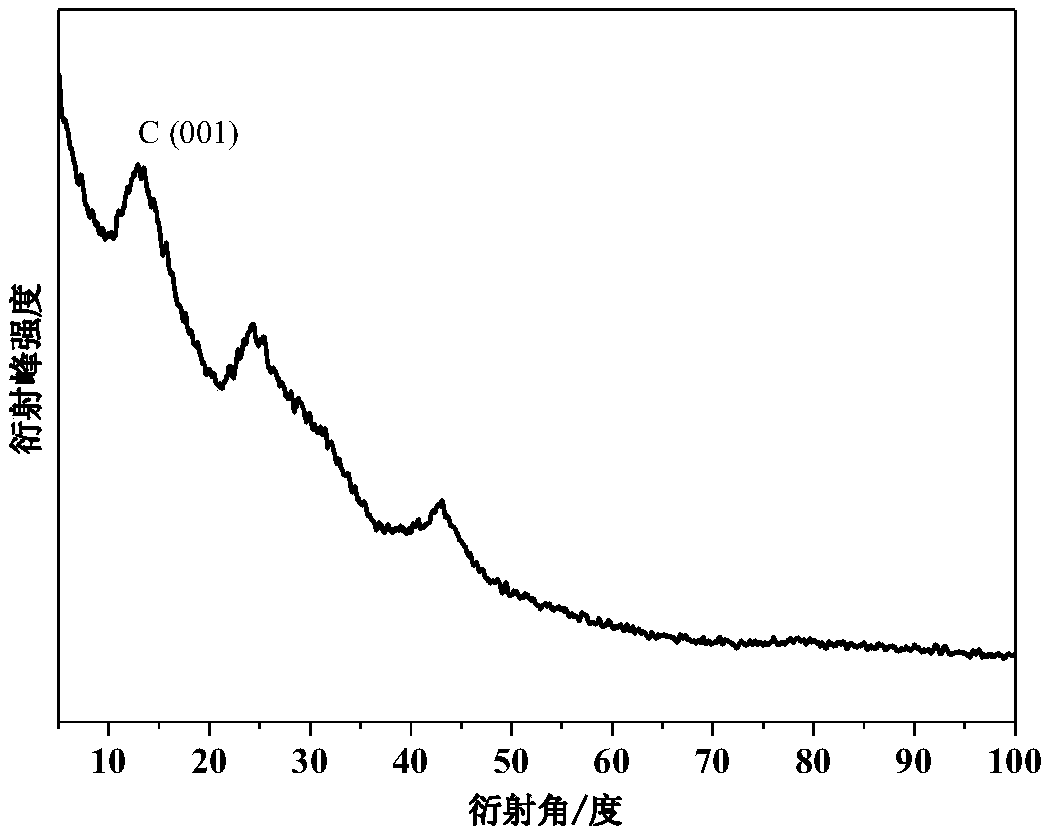

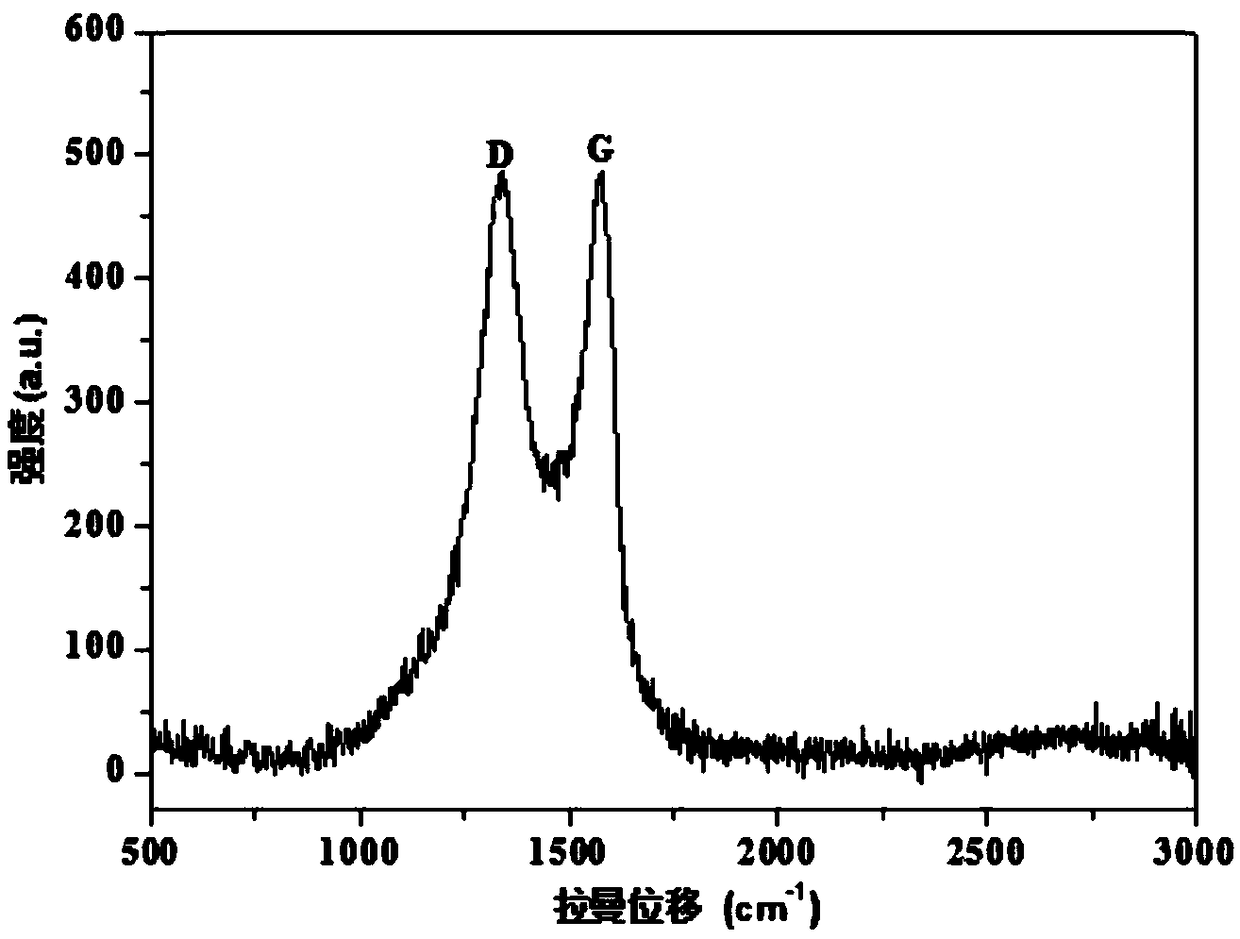

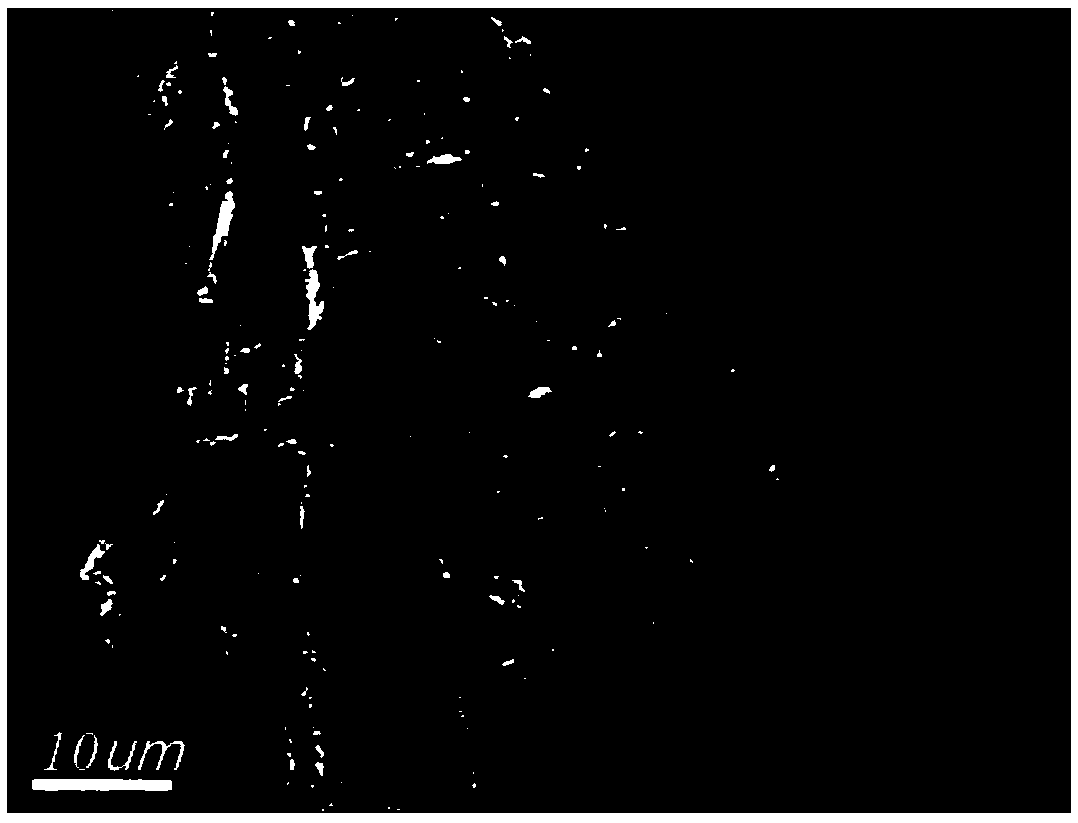

Image

Examples

Embodiment 1

[0032] (1) Wash the loofah and place it in a vacuum drying oven, carbonize and deoxidize at 180°C, degumming for 6 hours, then cool naturally to room temperature, and pulverize into powder for use. Soak commercially available nickel foam in 3mol / L hydrochloric acid for 15 minutes, wash it alternately with deionized water and acetone four times, and dry it in a vacuum oven at 60°C.

[0033] (2) Mix and grind the deoxidized and degummed loofah powder and sodium carbonate powder evenly in a mass ratio of 2:1, add 10mL of polyethylene glycol 400 dropwise and stir to form a slurry, and evenly coat it in step (1) purification On the treated nickel foam, an intermediate product is obtained.

[0034] (3) Put the intermediate product into a high-temperature tube furnace, and under the protection of high-purity nitrogen, raise the temperature to 1000°C at a constant speed of 10°C / min, and keep it warm for 2 hours. After cooling to room temperature, take the product out for use. Soak in...

Embodiment 2

[0037] (1) Wash the loofah and place it in a vacuum drying oven, carbonize and deoxidize at 190°C, degumming for 7 hours, then cool naturally to room temperature, and pulverize into powder for use. Soak commercially available nickel foam in 3mol / L hydrochloric acid for 15 minutes, wash it alternately with deionized water and acetone four times, and dry it in a vacuum oven at 60°C.

[0038] (2) Mix and grind the deoxidized and degummed loofah powder and sodium carbonate powder evenly in a mass ratio of 2:2, add 11mL of polyethylene glycol 400 dropwise and stir to form a slurry, and evenly coat it in step (1) purification On the treated nickel foam, an intermediate product is obtained.

[0039] (3) Put the intermediate product into a high-temperature tube furnace, and under the protection of high-purity nitrogen, raise the temperature to 1100°C at a constant speed of 10°C / min, and keep it warm for 3 hours. After cooling to room temperature, take the product out for use. Soak in...

Embodiment 3

[0042] (1) Wash the loofah and place it in a vacuum drying oven, carbonize and deoxidize at 200°C, degumming for 8 hours, then cool naturally to room temperature, and pulverize into powder for use. Soak commercially available nickel foam in 3mol / L hydrochloric acid for 15 minutes, wash it alternately with deionized water and acetone four times, and dry it in a vacuum oven at 60°C.

[0043] (2) Mix and grind the deoxidized and degummed loofah powder and sodium carbonate powder evenly according to the mass ratio of 2:3, add 12mL polyethylene glycol 400 dropwise and stir to form a slurry, and evenly coat in step (1) On the purified nickel foam, an intermediate product is obtained.

[0044] (3) Put the intermediate product into a high-temperature tube furnace, and under the protection of high-purity nitrogen, raise the temperature to 1200 °C at a constant speed of 10 °C / min, and keep it warm for 4 hours. After cooling to room temperature, the product is taken out for use Soak in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com