Environment-friendly device and process for reducing smoke plume in flue gas

An environmental protection device and flue gas technology, applied in gas treatment, gaseous effluent wastewater treatment, water/sludge/sewage treatment, etc., can solve the problem that the structure of the glass plate heat exchanger is not specified, and the haze is getting worse , complex process and other issues, to achieve the effect of improving hydrodynamic performance, wide applicability and reducing greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

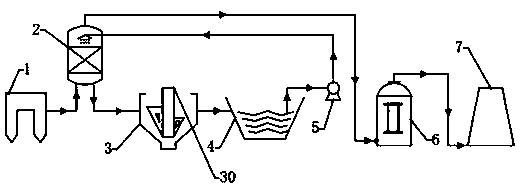

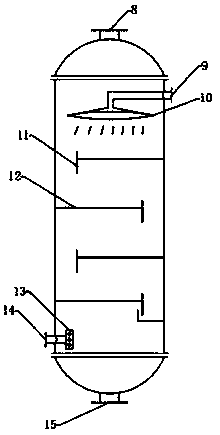

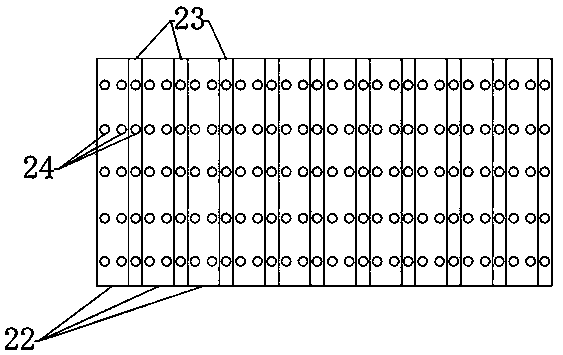

[0035] Such as Figure 1~6 As shown, an environmental protection device for reducing smoke plume in flue gas includes a flue gas desulfurization device 1, and the flue gas desulfurization device 1 is followed by an absorption tower 2, a sedimentation tank 3, a clear water tank 4, a centrifugal pump 5, and an electric trap 6. Chimney 7, the flue gas outlet of the flue gas desulfurization device 1 is connected to the air inlet 14 on the side of the absorption tower 2, the liquid outlet 15 at the bottom of the absorption tower 2 is connected to the sedimentation tank 3, and the sedimentation tank 3 is provided with a stirring device 30, used to deal with impurities in the absorbent; the sedimentation tank 3 is connected to the clean water tank 4, and the clean water tank 4 is connected to the liquid inlet 9 on the side of the absorption tower 2 through the centrifugal pump 5; the gas outlet 8 on the upper part of the absorption tower 2 is connected for electric capture The electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com