Acidic environment-friendly cleaning agent and preparation method thereof

A cleaning agent and environmental protection technology, applied in the field of cleaning agents, can solve the problems of non-recyclable use, high cost of waste liquid treatment, waste gas generation, etc., and achieve good synergistic effect and strong ability to complex Fe ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

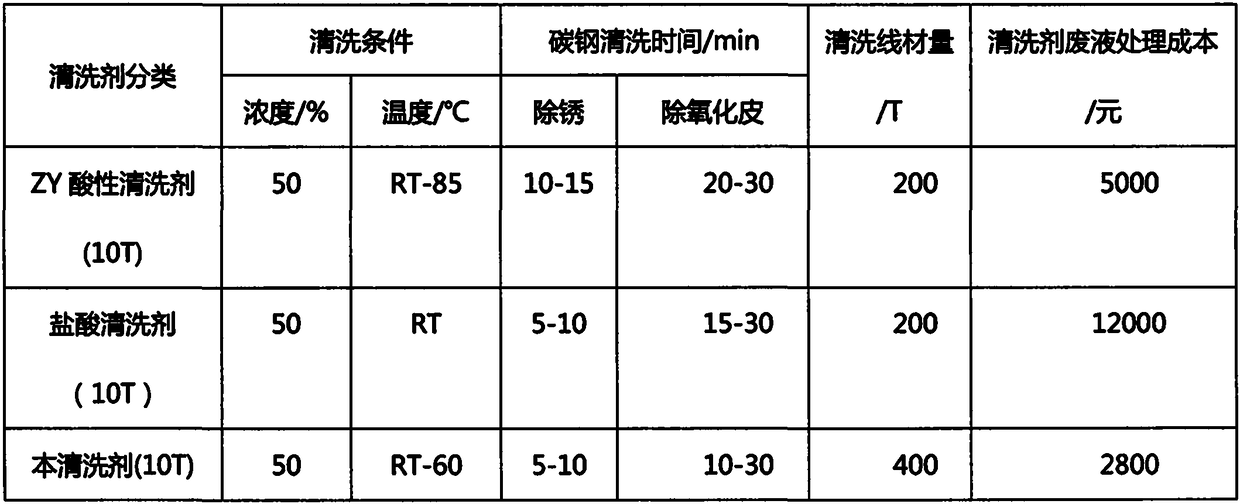

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of above-mentioned acid environment-friendly cleaning agent is as follows:

[0042] (1) Group A raw materials: add an appropriate amount of water to a stainless steel container, add phosphoric acid in proportion, and stir magnetically for 5 minutes; Stir for 5 minutes; continue to add an appropriate amount of phytic acid to the container, stir magnetically for 5 minutes, continue to add appropriate amount of other organic acids to the container, and stir magnetically for 5-10 minutes.

[0043] (2) Group B raw materials: Add an appropriate amount of water into a stainless steel container, add an oxidizing agent into the container, and stir magnetically for 5-10 minutes until the oxidizing agent is completely dissolved.

[0044] (3) Group C raw materials: Add an appropriate amount of water into a glass beaker, heat to 80-90°C, add an appropriate amount of polymer dispersant, and stir magnetically for 50-60 minutes to fully dissolve the polymer dispe...

Embodiment 1

[0049] Calculated on the basis of 100 parts of cleaning agent, choose 20 parts of phosphoric acid, 5 parts of hydroxyethylidene diphosphonic acid HEDP, 1 part of phytic acid, 5 parts of citric acid, 1 part of tartaric acid, 2 parts of sodium nitrate as the oxidant, and 1 part of phytic acid. The dispersant is 2 parts of polyethylene glycol 2000, 0.5 part of organic corrosion inhibitor thiourea, 2 parts of organic penetrant JFC, and the balance of water.

[0050] The preparation method of above-mentioned cleaning agent is as follows:

[0051] (1) Group A raw materials: add 20 parts of water and 20 parts of phosphoric acid in a stainless steel container, and stir magnetically for 5 minutes; after the solution is cooled to room temperature, add 5 parts of hydroxyethylidene diphosphonic acid in the container, and stir magnetically for 5 minutes; Continue to add 1 part of phytic acid to the container, stir magnetically for 5 minutes, continue to add 5 parts of citric acid and 1 par...

Embodiment 2

[0057] Based on 100 parts of cleaning agent, choose 30 parts of phosphoric acid, 2 parts of hydroxyethylidene diphosphonic acid HEDP, 0.5 parts of phytic acid, 2 parts of glycolic acid and 1 part of formic acid for other organic acids, and 5 parts of ferric chloride as oxidant. Use 1 part of polyvinyl alcohol 1688 as molecular dispersant, 0.5 part of organic corrosion inhibitor oleic acid imidazoline, 2 parts of organic penetrating agent alkylphenol polyoxyethylene ether, and the rest of water.

[0058] Preparation method: (1) Group A raw materials: add 25 parts of water and 30 parts of phosphoric acid into a stainless steel container, and stir magnetically for 5 minutes; after the solution is cooled to room temperature, add 2 parts of hydroxyethylidene diphosphonic acid into the container, and stir magnetically 5 minutes; continue to add 0.5 parts of phytic acid to the container, stir magnetically for 5 minutes, continue to add 2 parts of glycolic acid, 1 part of formic acid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com