Hydrothermal preparation of ultrafine calcium silicon-phosphate powder and application thereof

A technology of fine silicon calcium phosphate and silicon calcium phosphate is applied in the field of medical materials, which can solve the problems of long process cycle and difficult sintering of powder, and achieves the effect of meeting application requirements, easy availability of raw materials and less agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention provides a kind of preparation method of superfine silicon calcium phosphate powder in the first aspect, comprises the steps:

[0057] (1) Mix calcium source, phosphorus source, silicon source and dispersant to obtain a mixture; wherein, the molar ratio of Ca in the calcium source, P in the phosphorus source and Si in the silicon source is 5:2:1;

[0058] In this step, the calcium source can be any one or more of easily soluble calcium source, soluble calcium source or slightly soluble calcium source; preferably, the calcium source is calcium nitrate, calcium chloride, calcium phosphate , any one or more of calcium dihydrogen phosphate, calcium hydrogen phosphate, and calcium hydroxide. Described phosphorus source can select the commonly used phosphorus source reagent for use, comparatively suitably has any in phosphoric acid, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, sodium phosphate, calcium phosphate, calcium dihydrogen phosp...

Embodiment 1

[0106] (1) Weigh 2.842gNa respectively 2 SiO 3 9H 2 O powder, 2.3405gCa(H 2 PO 4 ) 2 Powder, 2.9636gCa(OH) 2 powder, respectively poured into three small beakers, and dissolved in 15mL deionized water, Na 2 SiO 3 9H 2 O dissolved into a transparent solution, Ca(H 2 PO 4 ) 2 Slightly soluble, white suspension, Ca(OH) 2 Slightly soluble, white suspension. Observe Na 2 SiO 3 9H 2 After O is completely dissolved, the Ca(H 2 PO 4 ) 2 Slowly pour the suspension into the sodium silicate solution, stir with a magnetic stirrer while pouring, and then add Ca(OH) 2 The suspension was poured, and the resulting mixture was white, and stirred with a magnetic stirrer for 1 to 2 hours.

[0107] (2) Transfer 60mL of the mixed liquid to a 100mL hydrothermal reaction kettle, and the hydrothermal reaction is carried out in a homogeneous reactor, and the reaction conditions are 180°C, 24h, 15 rpm.

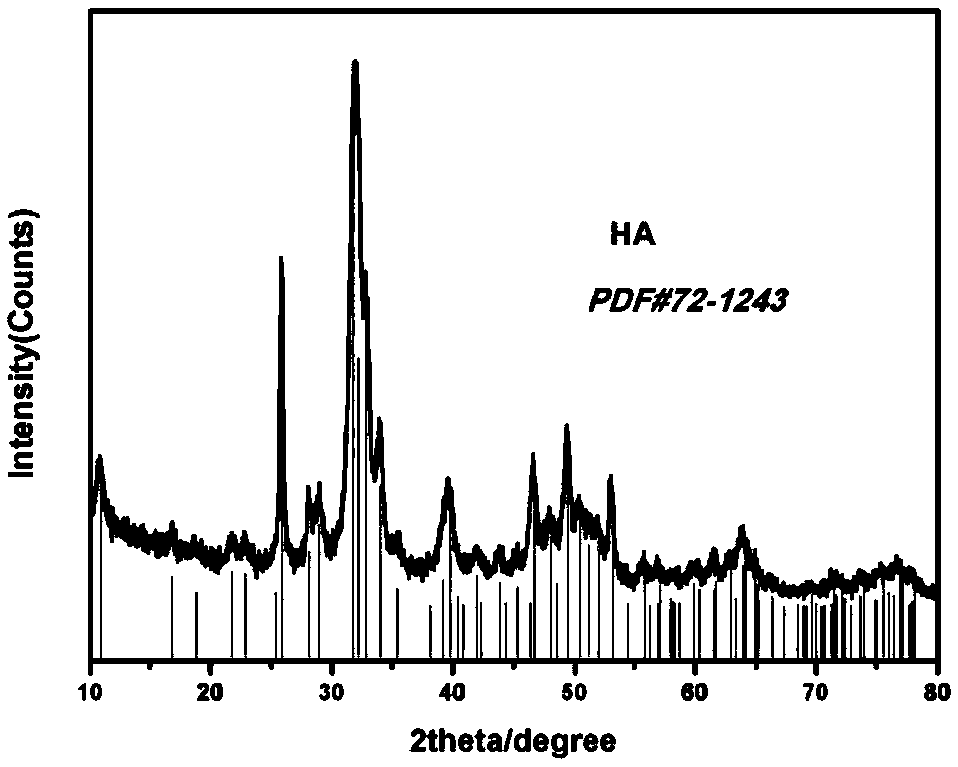

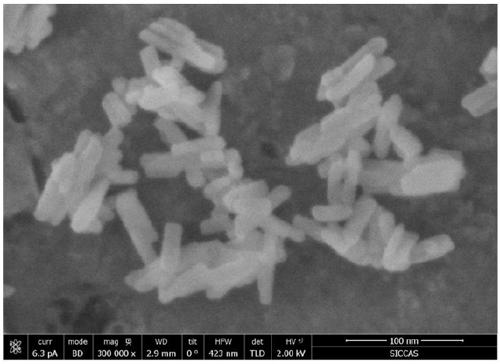

[0108] (3) After the reaction, the white precipitated solution in the hydrother...

Embodiment 2

[0112] (1) With embodiment 1.

[0113] (2) With embodiment 1.

[0114] (3) with embodiment 1.

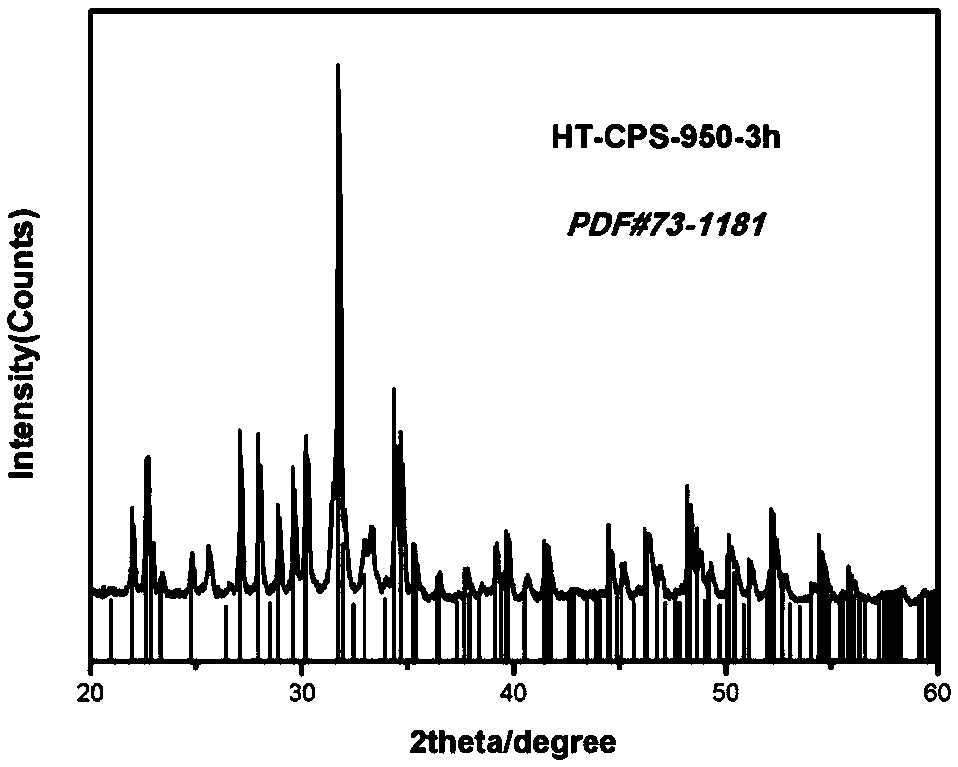

[0115](4) The finished precursor is calcined at a high temperature of 950°C under conventional atmospheric pressure, the heating rate is 5°C / min, and the temperature is kept at 950°C for 6 hours to obtain calcium silicon phosphate (Ca 5 (PO 4 ) 2 SiO 4 ) powder.

[0116] Carry out XRD test to the prepared silicon calcium phosphate powder, the phase is pure phase silicon calcium phosphate, consistent with the standard card (PDFNo.73-1181) (such as Figure 5 ). Scanning electron microscope observes the morphology of the silicon calcium phosphate powder of preparation (such as Figure 6 ), the particle size of the powder is between 200nm and 300nm, and the particle shape of the powder is irregular, which increases compared to the particle size of the powder calcined at 950°C / 3h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com