Non-yellowing polyurethane one-component moisture curing agent and preparation method thereof

A moisture curing agent, polyurethane single technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of affecting product color and performance, unable to meet long-term use, easy oxidation, yellowing, etc., to achieve low equipment cost, The effect of uniform molecular weight distribution and not easy to age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

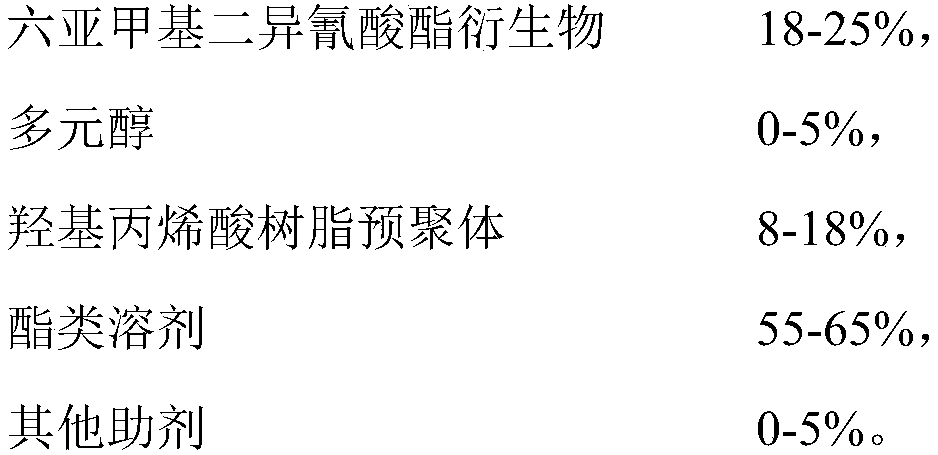

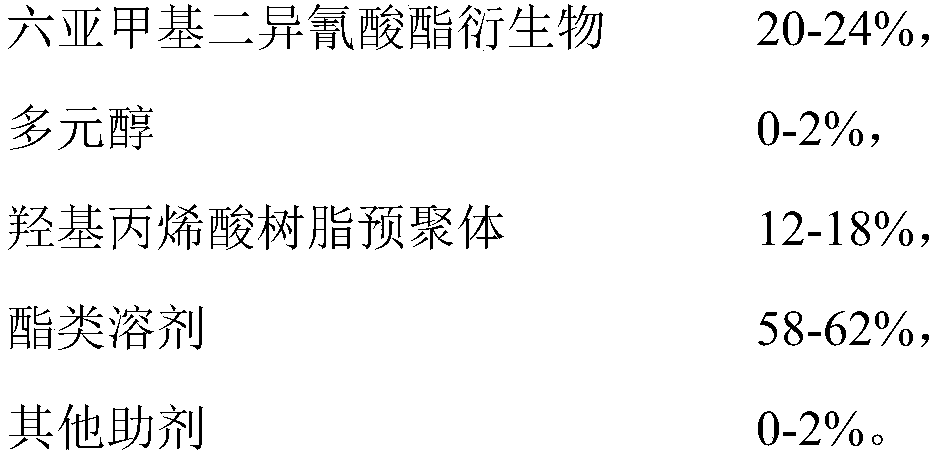

Method used

Image

Examples

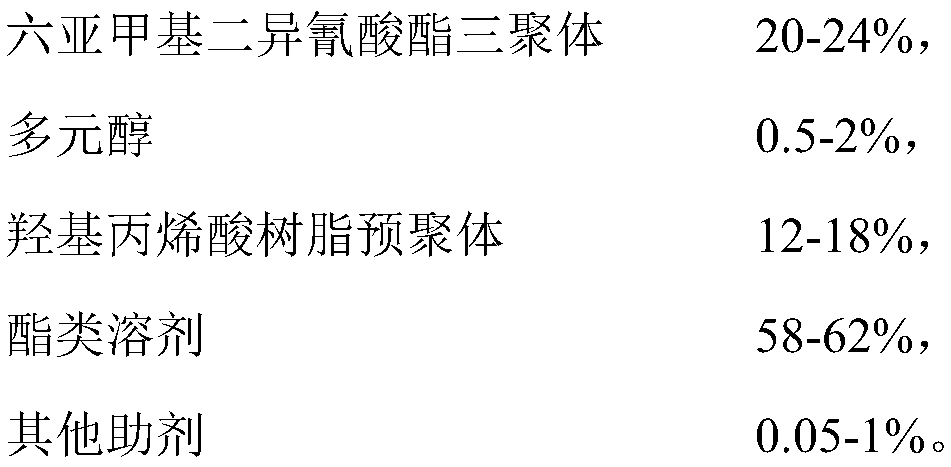

Embodiment 1

[0046]233.3g hexamethylene diisocyanate trimer, 8g trimethylolpropane, 158.5g hydroxy acrylic resin prepolymer, 600g ethyl acetate, 0.2g tetra[beta-(3,5-di-tert-butyl- 4-Hydroxyphenyl)propionic acid] pentaerythritol ester, 0.2g defoamer and 0.2g leveling agent were mixed, preheated at 60°C for 2h, then heated at 80°C for 4h, cooled to After 60°C, filter and discharge to obtain a one-component moisture curing agent for non-yellowing polyurethane.

[0047] In Example 1, the hydroxy acrylic resin prepolymer was prepared by the following method: 30% of ethyl acrylate, 30% of ethyl methacrylate, 15% of hydroxyethyl acrylate, 20% of hydroxybutyl acrylate and di-tertiary peroxide 4% amyl group was mixed, heated at 125°C for 6 hours, cooled to 90°C, 1% hydroquinone was added, and the residual monomer was removed by vacuuming to obtain a hydroxyacrylic resin prepolymer.

Embodiment 2

[0049] 233.3g hexamethylene diisocyanate trimer, 8g methyl propylene glycol, 158.5g hydroxy acrylic resin prepolymer, 600g butyl acetate, 0.2g tetra[beta-(3,5-di-tert-butyl-4- Hydroxyphenyl)propionic acid] pentaerythritol ester, 0.2g defoamer and 0.2g leveling agent were mixed, preheated at 60°C for 2h, then heated at 80°C for 4h, cooled to 60°C Then, filter and discharge to obtain a one-component moisture curing agent for non-yellowing polyurethane.

[0050] In Example 2, the hydroxyacrylic resin prepolymer was prepared by the following method: methyl acrylate 25%, ethyl methacrylate 40%, hydroxyethyl methacrylate 15%, hydroxybutyl acrylate 17% and peroxide Di-tert-amyl 2.5% was mixed, heated at 125°C for 6 hours, cooled to 90°C, added with 0.5% hydroquinone, and vacuumed to remove residual monomers to obtain a hydroxyacrylic resin prepolymer.

Embodiment 3

[0052] 231.9g hexamethylene diisocyanate trimer, 10.5g neopentyl glycol, 157.5g hydroxy acrylic resin prepolymer, 600g ethyl acetate, 0.2g tetra[beta-(3,5-di-tert-butyl- 4-Hydroxyphenyl)propionic acid] pentaerythritol ester, 0.2g defoamer and 0.2g leveling agent were mixed, preheated at 60°C for 2h, then heated at 80°C for 4h, cooled to After 60°C, filter and discharge to obtain a one-component moisture curing agent for non-yellowing polyurethane.

[0053] In Example 3, the hydroxyacrylic resin prepolymer was prepared by the following method: mixing 70% methyl methacrylate, 28% ethyl hydroxyacrylate and 1.5% di-tert-amyl peroxide, and heating at 125°C The reaction was carried out for 6 h, the temperature was lowered to 90° C., 0.5% hydroquinone was added, and the residual monomer was removed by vacuuming to obtain a hydroxyacrylic resin prepolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com