Rare earth ferrosilicon alloy ash-based composite material, logistics tray and preparation method thereof

A technology of rare earth ferrosilicon alloy and composite materials, which is applied in the direction of sustainable manufacturing/processing, containers, packaging recycling, etc., can solve the problems of ordinary plastic trays such as low strength, low carrying capacity, easy aging and non-durability, and achieve waterproof and anti-corrosion. Repeated use, reasonable structure design, good waterproof and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a preparation method of the logistics tray, comprising the following steps:

[0055] (1) polyvinyl chloride, stabilizer, modifying agent, blowing agent, foam regulator and lubricant are mixed to obtain the first mixture;

[0056] (2) heating the first mixture to a first-order temperature and mixing it with rare earth ferrosilicon alloy ash to obtain a second mixture;

[0057] (3) raising the temperature of the second mixture to the second-order temperature and then lowering to the third-order temperature for insulation, and finally lowering to room temperature to obtain the raw material mixture;

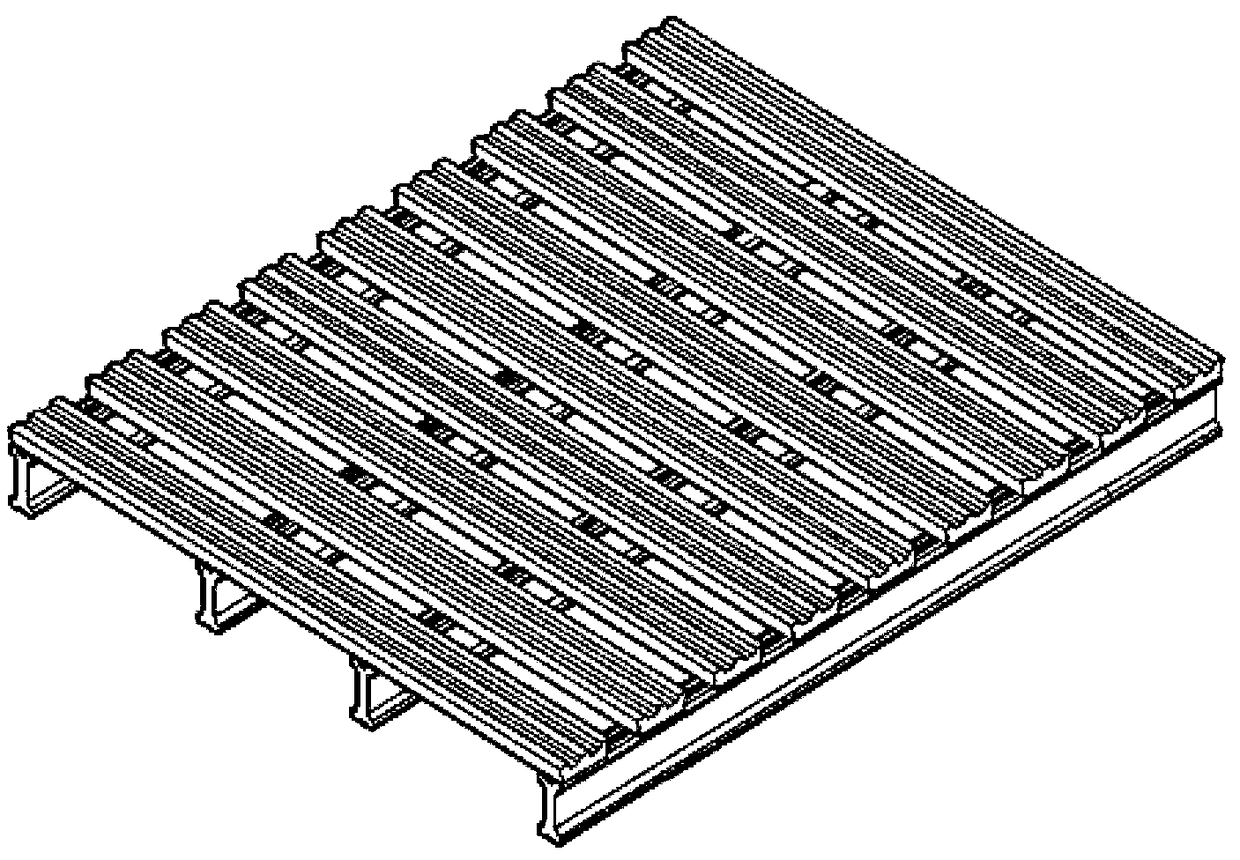

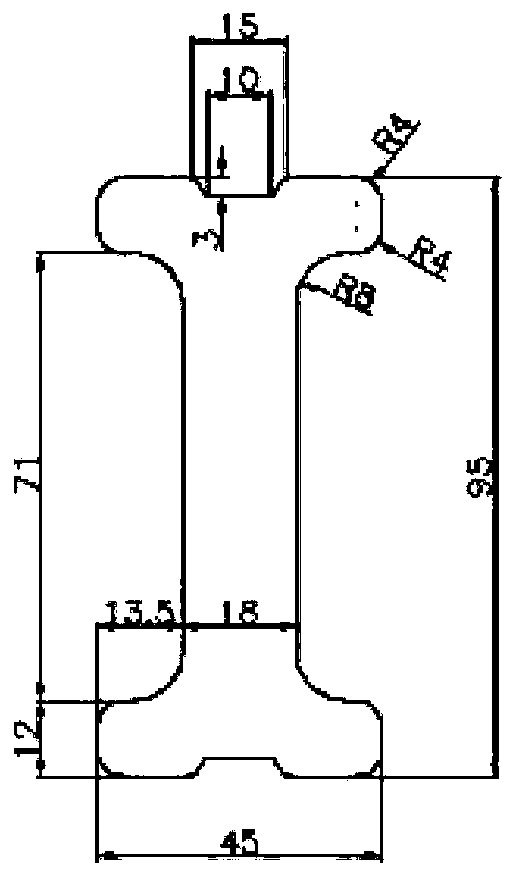

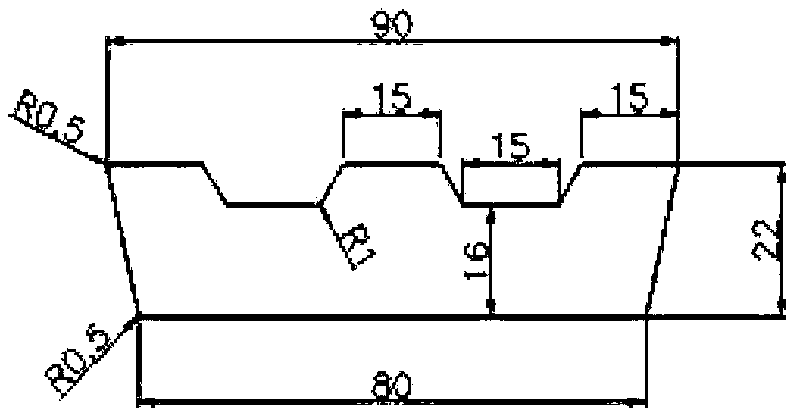

[0058] (4) using the raw material mixture to extrude respectively to obtain a base member and a panel member;

[0059] (5) Assemble the base component and the panel component to obtain a logistics tray.

[0060] The invention mixes polyvinyl chloride, stabilizer, modifying agent, foaming agent, foam regulator and lubricant to obtain the fi...

Embodiment 1

[0072] According to the composition of mass parts: 40 parts of rare earth ferrosilicon alloy ash, 47 parts of PVC (8 series), 3 parts of lead salt composite stabilizer, 4 parts of modifier (dioctyl phthalate), foaming agent (azo Diformamide and sodium bicarbonate are used together, mass ratio is 1:2) 1.5 parts, foam regulator (polymethyl acrylate) 4 parts, first lubricant stearic acid 0.3 parts, second lubricant (paraffin wax) 0.2 parts are weighed;

[0073] First mix PVC, stabilizer, modifier, foaming agent, foaming regulator and lubricant evenly together, heat to 105°C; then add rare earth ferrosilicon alloy ash to it, heat and mix to 125°C; finally mix the material Cool down to 45°C and stir for 20 minutes, then cool down to room temperature naturally and store for later use;

[0074] Extrude the mixed raw materials with an extrusion molding machine. The temperature of barrel 1 is 170°C, the temperature of barrel 2 is 178°C, the temperature of barrel 3 is 175°C, the temper...

Embodiment 2

[0078] According to the composition of mass parts: 38 parts of rare earth ferrosilicon alloy ash, 50 parts of PVC (8 series), 2 parts of rare earth composite stabilizer, 3 parts of modifier (chlorinated polyethylene), foaming agent (azodicarbonamide and Sodium bicarbonate is used together, the mass ratio is 1:2) 1.7 parts, foam regulator (polymethyl methacrylate) 4.8 parts, first lubricant stearic acid 0.2 parts, second lubricant (paraffin wax) 0.3 parts carry out weighing;

[0079] First mix PVC, stabilizer, modifier, foaming agent, foaming regulator and lubricant evenly together, and heat to 100°C; then add rare earth ferrosilicon alloy ash to it, heat and mix to 120°C; finally mix the material Cool down to 40°C and stir for 20 minutes, then cool down to room temperature naturally and store for later use;

[0080] Extrude the mixed raw materials with an extrusion molding machine. The temperature of barrel 1 is 168°C, the temperature of barrel 2 is 175°C, the temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com