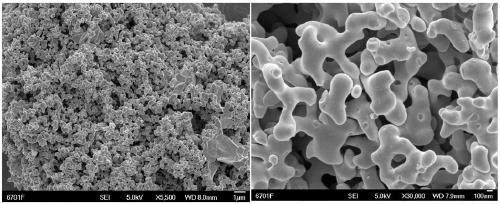

3D cross-linked coralloid nickle vanadate nanometer material and electrochemical application thereof

A nano-material, coral-like technology, applied in the field of coral-like nickel vanadate nano-materials and its electrochemical applications, can solve the problems of cumbersome operation, low specific surface area of pure nickel vanadate materials, many steps of sol method, etc. Effects of surface area, uniform morphology, ease of handling and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of the 3D crosslinked coral-like nickel vanadate nanomaterial of the present embodiment is: carry out the synthetic reaction of ammonium metavanadate (vanadium source) and nickel nitrate (nickel source) in [Bmim]Br (ionic liquid), A 3D cross-linked coral-like nickel vanadate nanomaterial with a specific surface area of 150m 2 / g.

[0020] The conditions of the synthesis reaction are as follows: the reaction temperature is 180°C, the reaction time is 72h, the reaction pressure is normal pressure, the molar ratio of ammonium metavanadate to [Bmim]Br is 1:80, the ratio of ammonium metavanadate to nickel nitrate is The molar ratio is 1:1.5.

[0021] In this embodiment, the ionic liquid can also be [Bmim]Br, [Bmim]PF 6 、[Bmim]BF 4 、[Bmim]Tf 2 N. [Bmim] CF 3 SO 3 、[Emim]Br、[Emim]PF 6 、[Emim] BF 4 、[Emim]Tf 2 N. [Emim] CF 3 SO 3 , Choline Chloride / Urea Eutectic Mixture, Choline Chloride / Succinic Acid Eutectic Mixture or Choline Chloride / Oxal...

Embodiment 2

[0028] The preparation method of the 3D crosslinked coral-shaped nickel vanadate nanomaterial of the present embodiment is: ammonium vanadate (vanadium source) and nickel chloride (nickel source) are mixed in choline chloride / urea eutectic mixture (ionic liquid ) to carry out a synthesis reaction to obtain a 3D cross-linked coral-like nickel vanadate nanomaterial with a specific surface area of 130m 2 / g.

[0029] The mol ratio of urea and choline chloride in the described choline chloride / urea eutectic mixture is 0.6:1;

[0030] The conditions of the synthesis reaction are as follows: the reaction temperature is 210°C, the reaction time is 5h, the reaction pressure is normal pressure, the molar ratio of sodium molybdate to choline chloride / urea eutectic mixture is 1:80, ammonium vanadate The molar ratio with nickel chloride is 1:5.

[0031] In this embodiment, the ionic liquid can also be a choline chloride / succinic acid eutectic mixture or a choline chloride / oxalic acid ...

Embodiment 3

[0034] The preparation method of the 3D cross-linked coral-shaped nickel vanadate nanomaterial of the present embodiment is: vanadium pentoxide (vanadium source) and nickel acetate (nickel source) in choline chloride / succinic acid eutectic mixture ( ionic liquid) to carry out the synthesis reaction to obtain 3D cross-linked coral-like nickel vanadate nanomaterials with a specific surface area of 50m 2 / g.

[0035] The molar ratio of succinic acid and choline chloride in the choline chloride / succinic acid eutectic mixture is 1:1; the conditions of the synthesis reaction are: the reaction temperature is 100°C, and the reaction time is 144h, The reaction pressure is normal pressure, the molar ratio of vanadium atoms in vanadium pentoxide to choline chloride / succinic acid eutectic mixture is 1:5, and the molar ratio of vanadium atoms in vanadium pentoxide to nickel acetate is 1 : 0.5.

[0036] In this embodiment, the ionic liquid may also be a choline chloride / oxalic acid eute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com