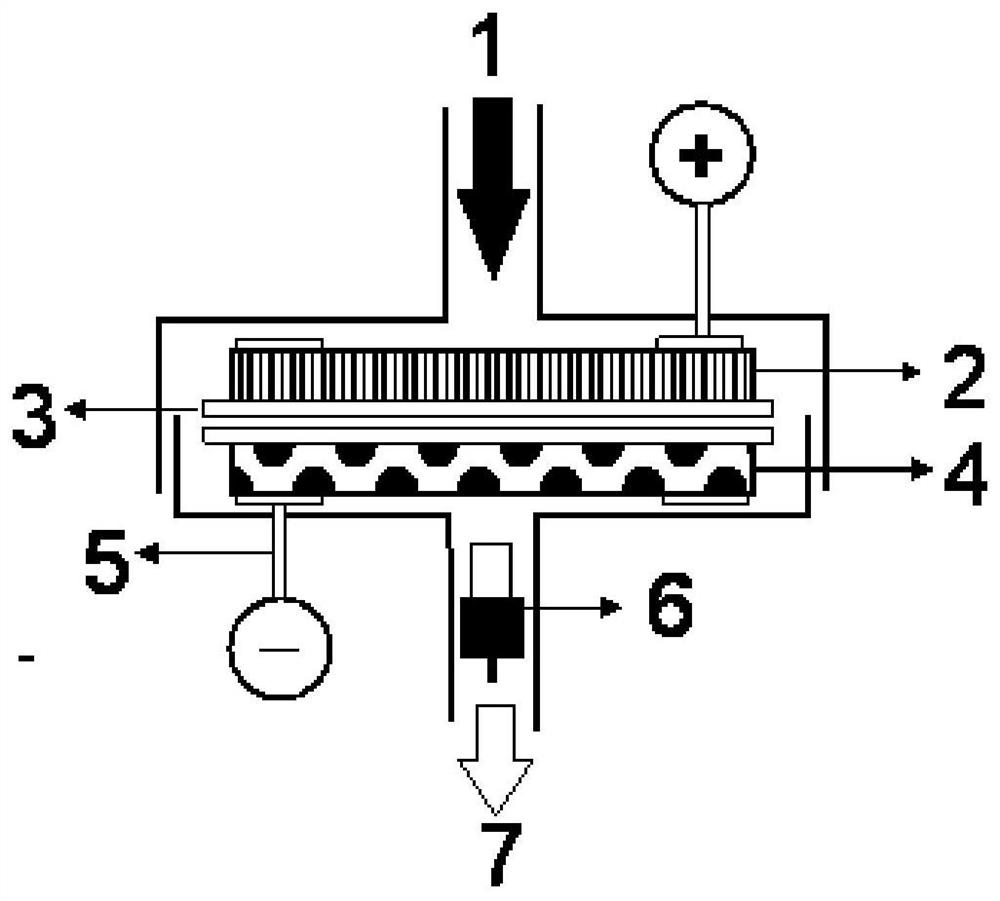

A Continuous Flow Electrochemical Filtration System and Its Application in Degrading Ammonia Nitrogen Wastewater

A technology for chemical filtration and degradation of ammonia nitrogen, applied in the direction of electrochemical water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problem of incomplete denitrification of ammonia nitrogen wastewater, and achieve low cost of raw materials and preparation , strong stability, easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 50mg Ti 4 o 7 Add 50mL of ultrapure water, and ultrasonically probe for 1h, and the evenly dispersed Ti 4 o 7 Suction filter onto PTFE support membrane, Ti 4 o 7 Film is too thin. Take 150mg Ti 4 o 7 Add 50mL of ultrapure water, and ultrasonically probe for 1h, and the evenly dispersed Ti 4 o 7 Suction filtration onto the PTFE support membrane, after freeze-drying, the measured resistance is about 30kΩ, which is too large. Take 100mg Ti 4 o 7 Add 50mL of ultrapure water, and ultrasonically probe for 1h, and the evenly dispersed Ti 4 o 7 Suction filtration onto the PTFE support membrane, after freeze-drying, the measured resistance is about 10kΩ, which is too large. Take 100mg Ti 4 o 7 Add 50mL of ultrapure water to 5mg of acidified CNT, and ultrasonically probe for 1h, and the evenly dispersed Ti 4 o 7 Suction filtration onto the PTFE support membrane, after freeze-drying, the measured resistance is about 100Ω, and the conductivity is very good. Th...

Embodiment 2

[0029] Take 100mg Ti 4 o 7 Add 50mL of ultrapure water to 5mg of acidified CNT, and ultrasonically probe for 1h, and the evenly dispersed Ti 4 o 7 Suction filter onto PTFE support membrane. Prepared Ti 4 o 7 The membrane acts as the anode in electrochemical filters.

[0030] Take 100 mL each of palladium chloride (2 mM), copper sulfate pentahydrate (4 mM), and hydrochloric acid (0.1 M) in the same beaker for 15 min and mix them evenly; in the three-electrode system, use Ni foam as the working electrode and Pt as the counter electrode electrode, and saturated Ag / AgCl as a reference electrode were immersed in the mixed solution together, and the electrodeposition experiment was carried out under the condition of the applied potential of -1.0V vs.Ag / AgCl, and the prepared Pd / Cu modified Ni foam Cathode in chemical filter.

[0031] Controlling the anode potential at 1.5V vs.Ag / AgCl, pH 7, initial concentration of Cl- at 0.1mol / L, controlling the flow rate from 1 to 4mL / min, t...

Embodiment 3

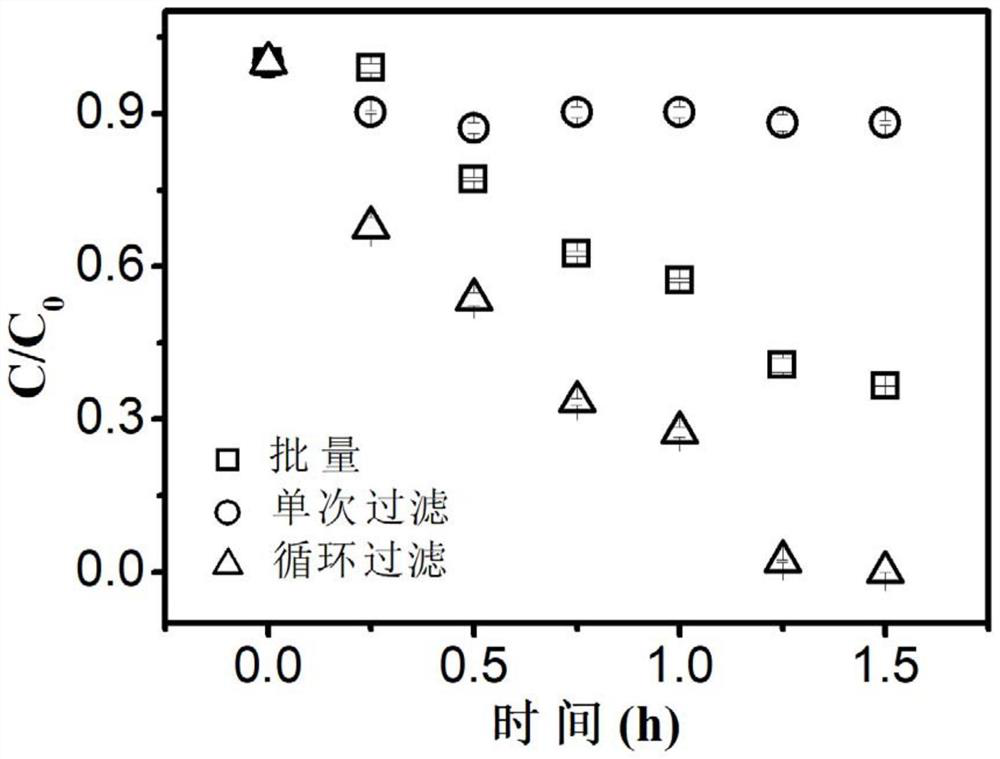

[0033] Anode Ti 4 o 7 The preparation method of thin film and cathode Pd / Cu modified Ni foam is the same as that of Example 2. Add 30mL of ammonia nitrogen wastewater with 0.175g of sodium chloride through the electrochemical filter device and return to the original beaker, and then re-enter the filter device for circulation filtration; add 30mL of ammonia nitrogen wastewater with 0.175g of sodium chloride through the electrochemical filter device and drip into a new beaker for a single filtration experiment; add 0.175g of sodium chloride to 30mL of ammonia nitrogen wastewater for a batch experiment. Control the anode potential at 2.5Vvs.Ag / AgCl, the pH is 7, [Cl - ] The initial concentration is 0.1mol / L. Such as figure 2 As shown, the removal rate of ammonia nitrogen in a single filtration experiment after 1.5 hours of reaction was 11.8%, the removal rate of ammonia nitrogen in a batch experiment was 63.6%, and the removal rate of ammonia nitrogen in a circulation filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com