Preparation method of super-heat-resistant and high-heat-conductivity epoxy plastic encapsulating material for encapsulating semiconductor

An epoxy plastic sealing compound, super heat-resistant technology, applied in the high thermal conductivity epoxy plastic sealing material, super heat-resistant field, can solve the problem that the epoxy plastic sealing material has too many solid fillers, can not effectively solve the raw material dispersion uniformity, poor mixing ability and other problems, to achieve the effect of increasing the glass transition temperature, improving thermal conductivity, and increasing heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

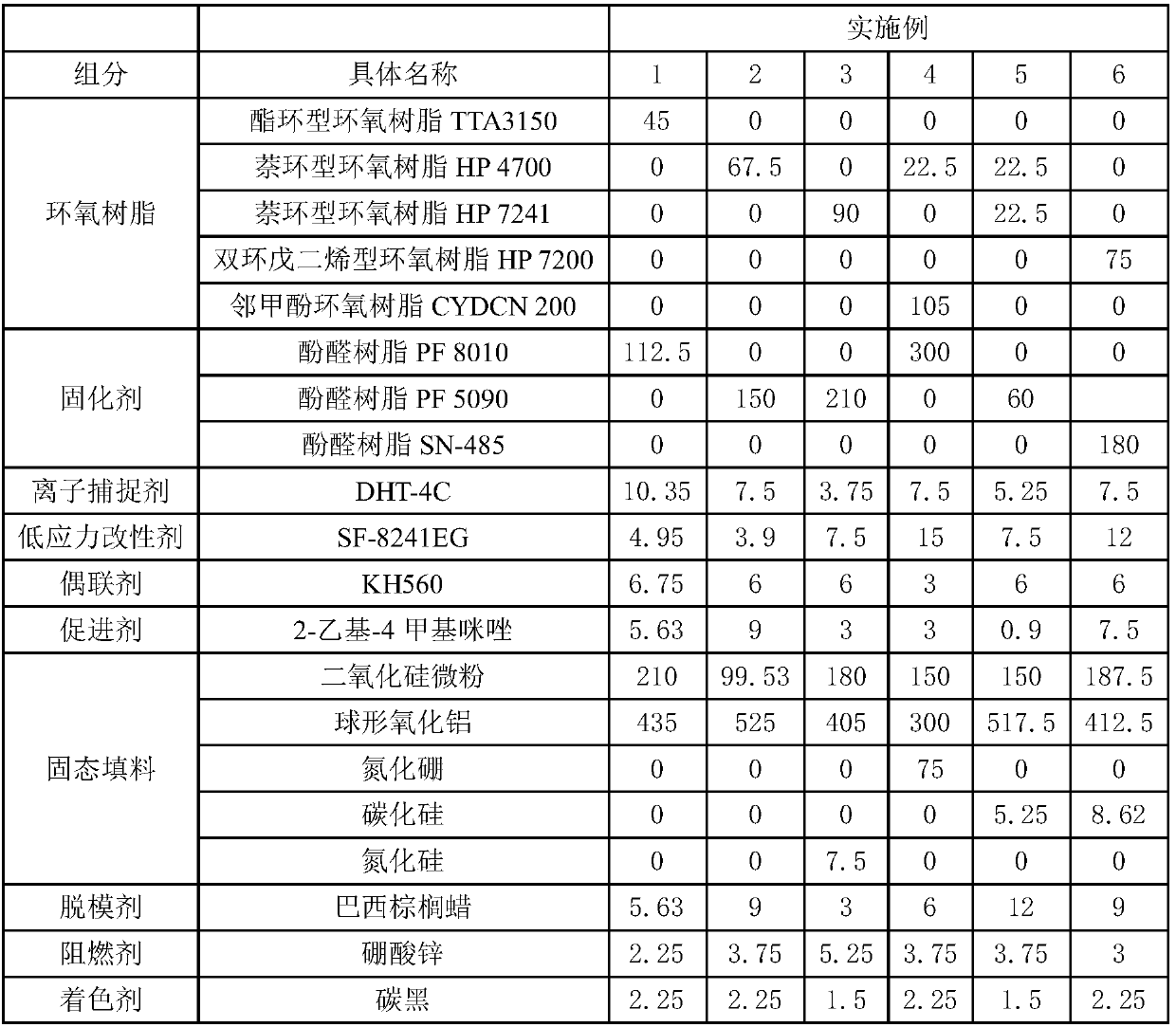

[0070] See Table 1 for the composition of the raw material formulation of the super heat-resistant, high thermal conductivity epoxy molding compound for semiconductor packaging in Example 1.

[0071] In this embodiment, the method for preparing super heat-resistant and high thermal conductivity epoxy molding compound for semiconductor packaging is as follows:

[0072] (1) 112.5g phenolic resin PF8010, 5.63g accelerator 2-ethyl-4 methylimidazole, 4.95g low stress modifier SF-8241EG, 6.75g coupling agent KH560 and 5.63g release agent carnauba wax Add it into the mixer and stir it at 150°C for 40 minutes. When the mixture in the container is melted and mixed well, it is cooled, pulverized and sieved for use.

[0073] (2) 45.15g of the mixture obtained in step (1), 45g of epoxy resin TTA 3150, 210g of silica powder, 435g of spherical alumina, 10.35g of ion trapping agent DHT-4C, 2.25g of flame retardant zinc borate and 2.25 g coloring agent carbon black was put into a high-speed ...

Embodiment 2

[0076] See Table 1 for the raw material formulation composition of the super heat-resistant, high thermal conductivity epoxy molding compound for semiconductor packaging in Example 2.

[0077] In this embodiment, the method for preparing super heat-resistant and high thermal conductivity epoxy molding compound for semiconductor packaging is as follows:

[0078] (1) Add 150g phenolic resin PF5090, 9g accelerator 2-ethyl-4 methylimidazole, 3.9g low stress modifier SF-8241EG, 6g coupling agent KH560 and 9g release agent carnauba wax to the mixer Stir at 170°C for 60 minutes, and when the mixture in the container is melted and mixed well, cool, pulverize and sieve for use.

[0079] (2) 44.48g of the mixture obtained in step (1), 67.5g of epoxy resin HP 4700, 99.53g of silica micropowder, 525g of spherical alumina, 7.5g of ion trapping agent DHT-4C, 3.75g of flame retardant zinc borate and 2.25g of colorant carbon black were put into a high-speed mixer and mixed for 8 minutes, and...

Embodiment 3

[0082] See Table 1 for the composition of the raw material formulation of the super heat-resistant, high thermal conductivity epoxy molding compound for semiconductor packaging in Example 3.

[0083] In this embodiment, the method for preparing super heat-resistant and high thermal conductivity epoxy molding compound for semiconductor packaging is as follows:

[0084] (1) Add 210g phenolic resin PF5090, 3g accelerator 2-ethyl-4 methylimidazole, 7.5g low stress modifier SF-8241EG, 6g coupling agent KH560 and 3g release agent carnauba wax to the mixer Inside, stir at 170°C for 50 minutes, and when the mixture in the container is melted and fully mixed, cool, pulverize and sieve for use.

[0085] (2) 57.37g of the mixture obtained in step (1), 90g of epoxy resin HP 7241, 180g of silica powder, 405g of spherical alumina, 7.5g of silicon nitride, 3.75g of ion trapping agent DHT-4C, 5.25g of resist The fuel zinc borate and 1.5g of the colorant carbon black were put into a high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com