Method for producing avermectins by fermentation by using air-lift loop reactor

A loop reactor and air-lift technology, applied in the field of microbial fermentation, can solve the problems of high production cost, low utilization rate of fermenter equipment, energy waste, etc., to improve oxygen and nutrient transfer efficiency, reduce energy consumption and bacterial contamination. efficiency, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

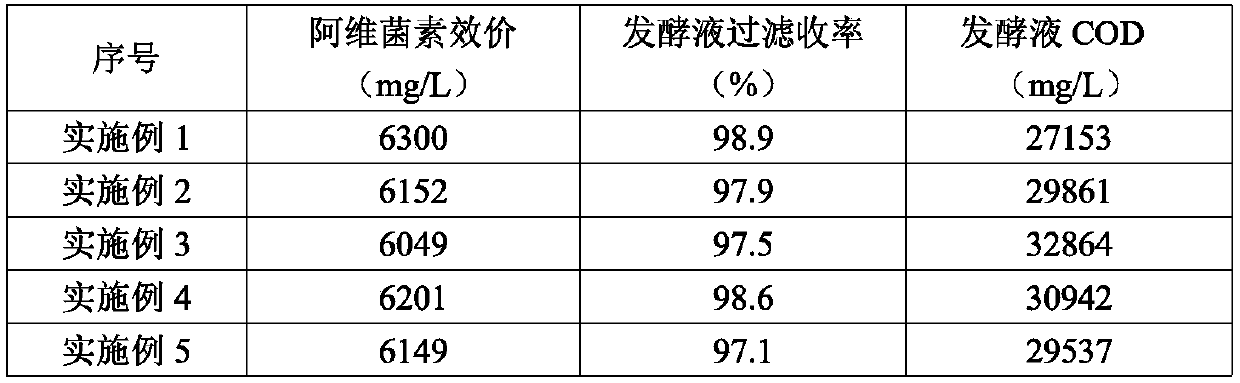

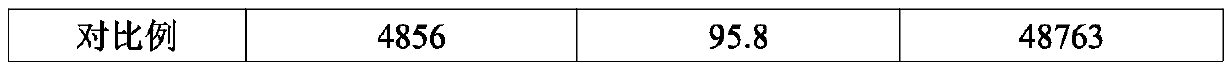

Examples

Embodiment 1

[0054] Embodiment 1 adopts method fermentation of the present invention to produce Abamectin

[0055] Incline medium (g / L): glucose 25, agar powder 25, beef extract 10, potassium dihydrogen phosphate 1, the balance is water, adjust the pH to 7.0, sterilize at 121°C for 30 minutes, cool to room temperature for later use;

[0056] Seed medium (g / L): 25 corn starch, 25 soybean cake powder, 12 yeast powder, 12 peanut powder, 2.5 antifoaming agent, the balance is water, adjust the pH to 7.0, sterilize at 121°C for 30 minutes, cool to room temperature for later use ;

[0057] Fermentation medium (g / L): corn starch 110, soybean cake powder 25, yeast powder 18, ammonium sulfate 0.5, calcium carbonate 2.5, defoamer 3, the balance is water, adjust the pH to 7.0, sterilize at 121°C for 30 minutes, Cool to room temperature for later use;

[0058] Feed medium (g / L): cornstarch 300, defoamer 0.6, calcium carbonate 2.5, dissolved in appropriate amount of water, sterilized at 121°C for 30 m...

Embodiment 2

[0066] Embodiment 2 adopts method fermentation of the present invention to produce Abamectin

[0067]The difference between embodiment 2 and embodiment 1 is that the feeding time in the fermentation process is different, specifically:

[0068] Incline medium (g / L): glucose 25, agar powder 25, beef extract 10, potassium dihydrogen phosphate 1, the balance is water, adjust the pH to 7.0, sterilize at 121°C for 30 minutes, cool to room temperature for later use;

[0069] Seed medium (g / L): 25 corn starch, 25 soybean cake powder, 12 yeast powder, 12 peanut powder, 2.5 antifoaming agent, the balance is water, adjust the pH to 7.0, sterilize at 121°C for 30 minutes, cool to room temperature for later use ;

[0070] Fermentation medium (g / L): corn starch 110, soybean cake powder 25, yeast powder 18, ammonium sulfate 0.5, calcium carbonate 2.5, defoamer 3, the balance is water, adjust the pH to 7.0, sterilize at 121°C for 30 minutes, Cool to room temperature for later use;

[0071]...

Embodiment 3

[0079] Embodiment 3 adopts method fermentation of the present invention to produce Abamectin

[0080] The difference between embodiment 3 and embodiment 1 is that the feeding time in the fermentation process is different, specifically:

[0081] Incline medium (g / L): glucose 25, agar powder 25, beef extract 10, potassium dihydrogen phosphate 1, the balance is water, adjust the pH to 7.0, sterilize at 121°C for 30 minutes, cool to room temperature for later use;

[0082] Seed medium (g / L): 25 corn starch, 25 soybean cake powder, 12 yeast powder, 12 peanut powder, 2.5 antifoaming agent, the balance is water, adjust the pH to 7.0, sterilize at 121°C for 30 minutes, cool to room temperature for later use ;

[0083] Fermentation medium (g / L): corn starch 110, soybean cake powder 25, yeast powder 18, ammonium sulfate 0.5, calcium carbonate 2.5, defoamer 3, the balance is water, adjust the pH to 7.0, sterilize at 121°C for 30 minutes, Cool to room temperature for later use;

[0084...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com