Self-layering, antifouling and easily-cleaned plastic tube and production method thereof

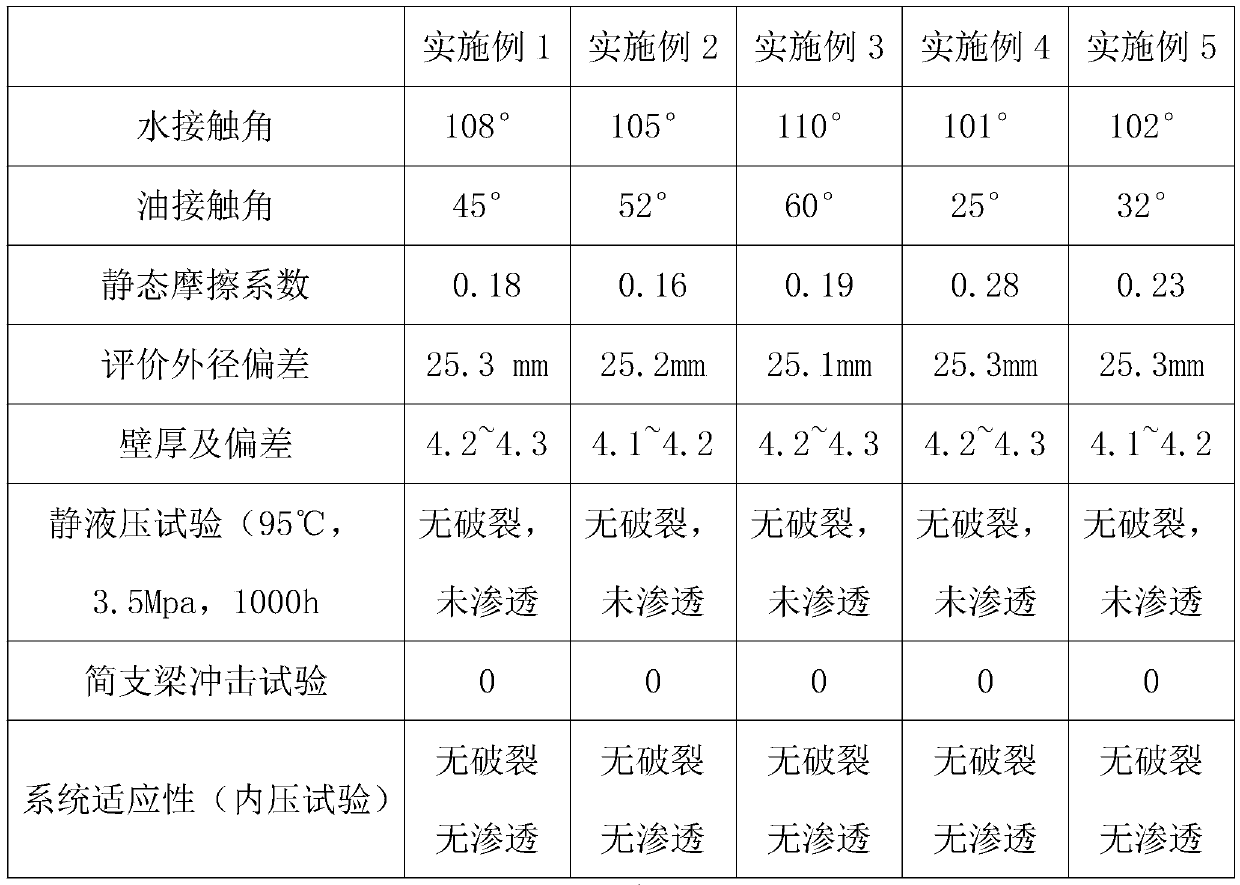

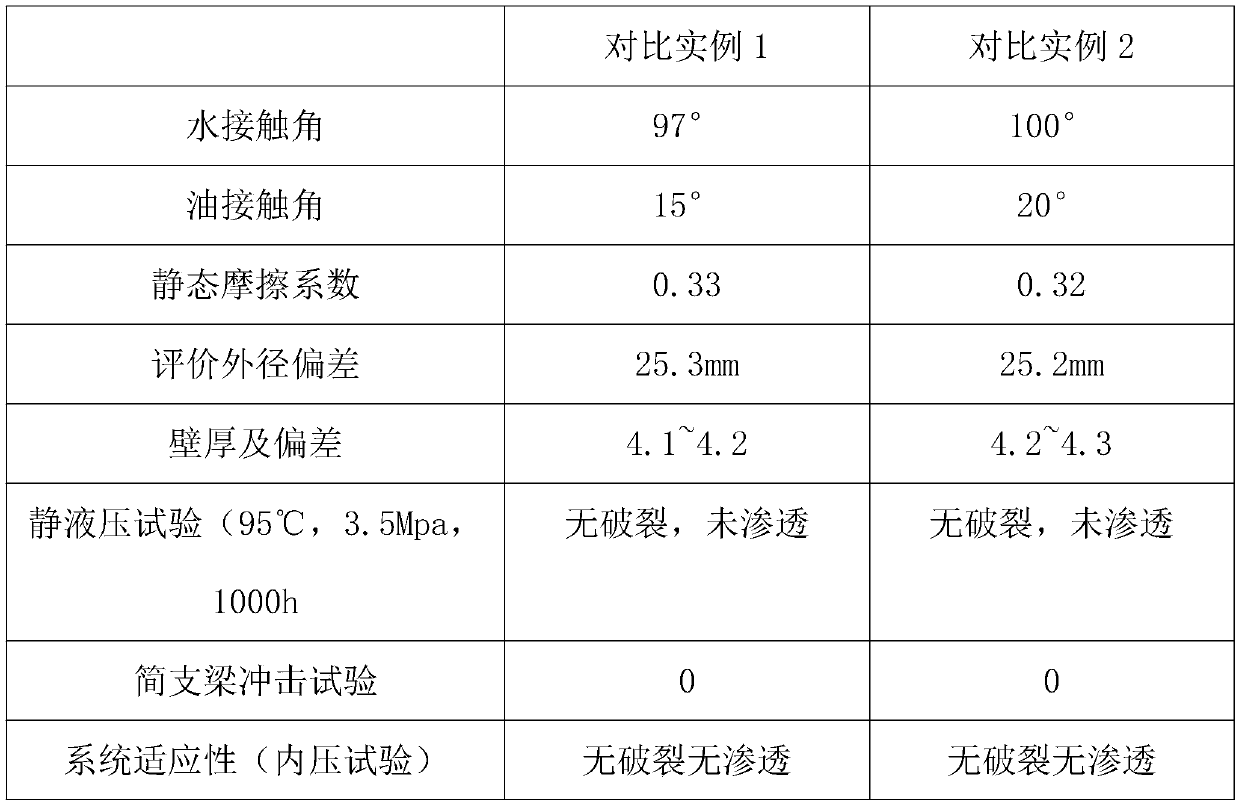

A plastic pipe, self-layering technology, applied in the field of self-layering, anti-fouling and easy-to-clean plastic pipes and preparation, can solve the problems of difficult processing, high cost, difficult large-scale application, etc., and achieves simple process, high water contact angle and oil The effect of small contact angle and static friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of self-layering antifouling cleaning plastic pipe comprises the following steps:

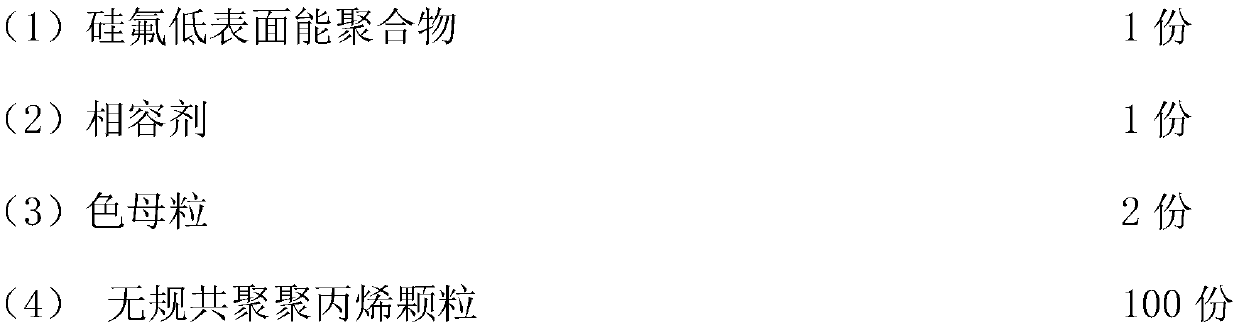

[0026] Step A. Preparation of self-layered antifouling masterbatch, raw materials are composed of the following components in parts by weight:

[0027] (1) Silicon fluorine low surface energy polymer 5 parts

[0028] (2) Compatibilizer 1 part

[0029] (3) 100 parts of polypropylene particles

[0030] The raw materials are all commercially available. The silicon-fluorine low surface energy polymer is PTFE F-205 polytetrafluoroethylene micropowder from Daikin Fluorochemical Co., Ltd., and the compatibilizer is maleic anhydride grafted polypropylene HD900P from Nanjing Huadu Industrial Co., Ltd. The propylene masterbatch is K1206 from Yanshan Petrochemical, with a melt index of 13.5g / min. R200P from South Korea Hyosung Co., Ltd. is used for random copolymerized polypropylene (PP-R) particles, and 4101 is used as masterbatch from Zhejiang Qiselu Masterbatch Co., Ltd...

Embodiment 2

[0039] The preparation method of self-layering antifouling cleaning plastic pipe comprises the following steps:

[0040] Step A. Preparation of self-layered antifouling masterbatch, raw materials are composed of the following components in parts by weight:

[0041] (1) Silicon fluorine low surface energy polymer 3 parts

[0042] (2) 2 parts of compatibilizer

[0043] (3) 100 parts of polypropylene particles

[0044] The raw materials are all commercially available. The silicon-fluorine low surface energy polymer is TG001 perfluoroalkyl functional polyolefin TG001 from Daikin Fluorochemical Co., Ltd., and the compatibilizer is P613 from DuPont, the maleic anhydride grafted polypropylene and polypropylene masterbatch. F30S from Shanghai Petrochemical Co., Ltd. is used, with a melt index of 13.5g / min. The PP-R random copolymerized polypropylene particles are R200P from Korea Hyosung Co., Ltd., and the masterbatch is 4101 from Zhejiang Qiseluse Masterbatch Co., Ltd.;

[0045] ...

Embodiment 3

[0053] The preparation method of self-layering antifouling cleaning plastic pipe comprises the following steps:

[0054] Step A. Preparation of self-layered antifouling masterbatch, raw materials are composed of the following components in parts by weight:

[0055] (1) Silicon fluorine low surface energy polymer 5 parts

[0056] (2) Compatibilizer 1 part

[0057] (3) 100 parts of polypropylene particles

[0058] The raw materials are all commercially available. The silicon-fluorine low surface energy polymer is TG001 perfluoroalkyl functional polyolefin TG001 from Daikin Fluorochemical Co., Ltd., and the compatibilizer is P613 from DuPont, the maleic anhydride grafted polypropylene and polypropylene masterbatch. The J740 of Yangzi Petrochemical is used, the melt index is 13.5g / min, the PP-R random copolymerized polypropylene particles are R200P of Korea Hyosung Co., Ltd., and the masterbatch is 4101 of Zhejiang Qiselu Masterbatch Co., Ltd.;

[0059] Melt blending silicon fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com