Low-halogen flame-retardant epoxy resin adhesive and preparation method thereof

A technology of epoxy resin glue and epoxy resin, applied in the direction of epoxy resin glue, adhesive, adhesive additive, etc., can solve the problems of reducing the properties of epoxy resin cured products, reducing mechanical properties, increasing curing temperature, etc. Overcome the effects of poor impact resistance, good flame retardant effect and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

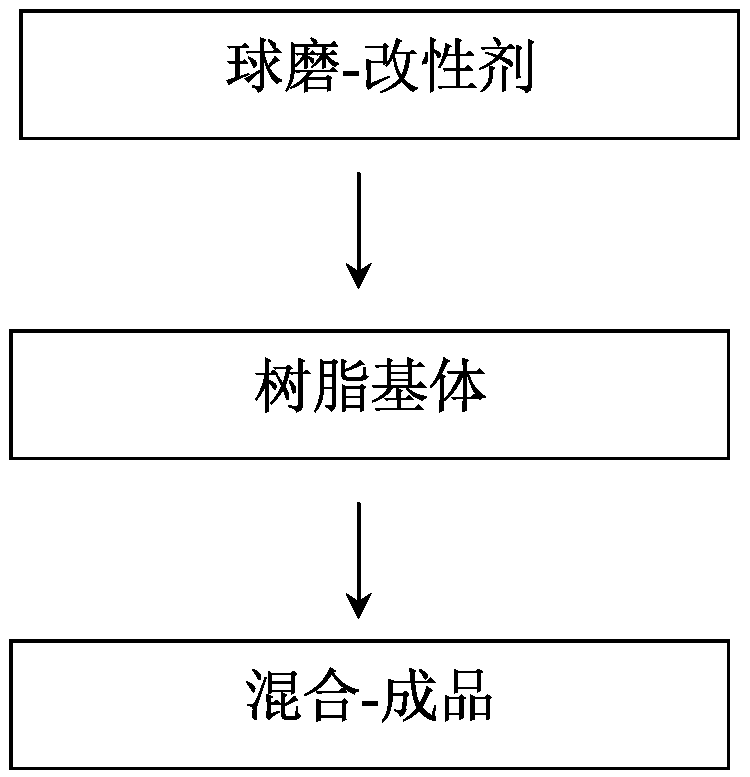

Method used

Image

Examples

Embodiment 1

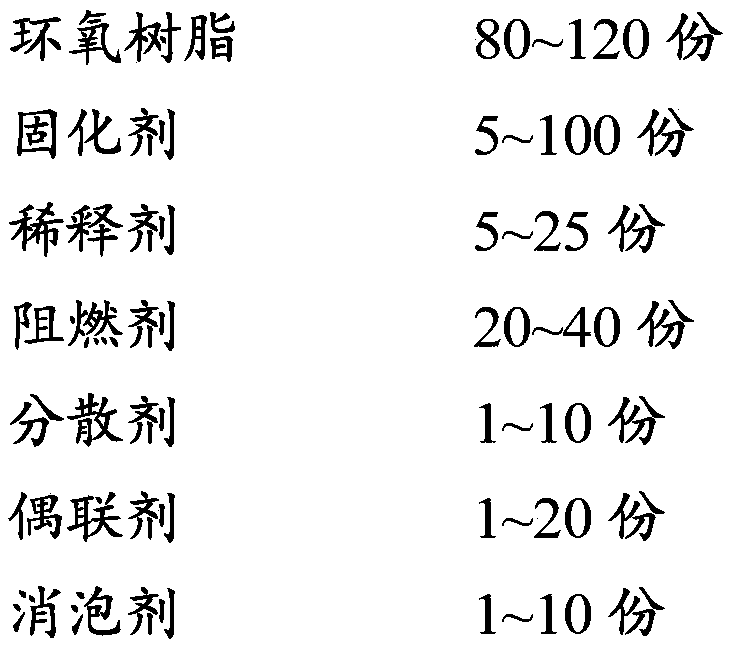

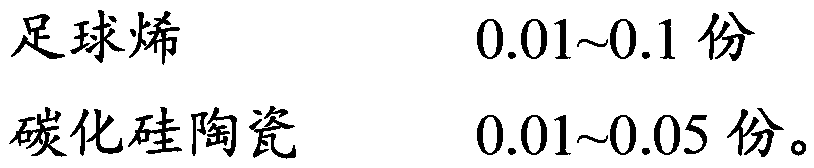

[0031] The low-halogen flame-retardant epoxy resin adhesive includes the following raw materials in parts by mass: 80 parts of epoxy resin (bisphenol A epoxy resin E-44), 5 parts of curing agent (dicyandiamide), 5 parts of diluent (dibutyl phthalate) 5 parts, flame retardant (aluminum hydroxide) 20 parts, dispersant (polyacrylamide) 1 part, coupling agent (γ-(methacryloxy) propyl trimethoxy Silane) 1 part, defoamer (glyceryl stearate) 1 part, football ene 0.01 part, silicon carbide ceramics 0.05 part.

Embodiment 2

[0033] The low-halogen flame-retardant epoxy resin adhesive includes the following raw materials in parts by mass: epoxy resin (hydrogenated bisphenol A type epoxy resin GEST3000 and bisphenol A type epoxy resin E-51 mixed resin, the mass of both The ratio is 1:1) 100 parts, the curing agent (the mixture of acetic anhydride and diaminodiphenylmethane, the mass ratio of the two is 1:10) 15 parts, the diluent (the mixture of acetone and n-butyl glycidyl ether, the mass ratio of the two The ratio is 5:1) 10 parts, the flame retardant (the mixture of zinc borate and phosphoramidate, the mass ratio of the two is 0.1:1) 60 parts, the dispersant (the mixture of polyacrylamide and zinc stearate, the mass ratio of the two 10:1) 5 parts, coupling agent (γ-aminopropyl triethoxysilane, isopropyl tristearyl titanate mixture, its mass ratio is 1:2) 10 parts, defoamer ( Glyceryl stearate) 10 parts, football ene 0.05 parts, silicon carbide ceramics 0.02 parts.

Embodiment 3

[0035] The low-halogen flame-retardant epoxy resin adhesive includes the following raw materials in parts by mass: epoxy resin (hydrogenated bisphenol A type epoxy resin GEST3000 and bisphenol A type epoxy resin E-51 mixed resin, the mass of both The ratio is 3:1) 100 parts, the curing agent (the mixture of acetic anhydride and diaminodiphenylmethane, the mass ratio of the two is 1:8) 15 parts, the diluent (the mixture of acetone and n-butyl glycidyl ether, the mass ratio of the two The ratio is 3:1) 10 parts, the flame retardant (the mixture of zinc borate and phosphoramidate, the mass ratio of the two is 1:5) 60 parts, the dispersant (the mixture of polyacrylamide and zinc stearate, the mass ratio of the two 2:1) 5 parts, coupling agent (γ-aminopropyl triethoxysilane, isopropyl tristearyl titanate mixture, its mass ratio is 1:5) 10 parts, defoamer ( Glyceryl stearate) 10 parts, football ene 0.05 parts, silicon carbide ceramics 0.02 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com