Manganese doped composite aluminate red luminescent material as well as preparation method and purpose thereof

A composite aluminate, red luminescence technology, applied in the field of luminescent material preparation, can solve the problems of harsh synthesis conditions, high preparation cost, poor thermal stability of red phosphors, etc., achieves simple preparation method, improved color rendering index, and preparation method Mature and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 prepares Mg 4 Al 14 o 25 Luminescent material

[0045] According to the general chemical formula Mg 4 Al 14 o 25 :xMn 4+ (x=0) each reactant required by weighing, the raw material is: MgO or MgCO 3 One or a mixture of two, Al 2 o 3 or Al 2 (CO 3 ) 3 one or a mixture of both. Put the required raw materials in an oven to fully dry, add a certain amount of absolute ethanol, the ratio of the volume of absolute ethanol to the mass of all reactants is 1-2mL: 1g, in order to make the reaction fully, add 5-10% by weight to the raw materials Ratio of co-solvent H 3 BO 3 . Then grind and mix evenly, place the obtained grinding mixture in a muffle furnace, first burn it for the first time, the burning temperature is 400°C, and the time is 0.5-2 hours, after cooling, grind and pulverize the obtained material; Put it back in the muffle furnace for the second burning, the temperature of the second burning is 1100-1800 ° C, and the time is 2-10 hours to ob...

Embodiment 2

[0046] Embodiment 2 prepares Mg 4 Al 14 o 25 :0.005Mn 4+ Luminescent material

[0047] According to the general chemical formula Mg 4 Al 14 o 25 :xMn 4+ (x=0.005) each reactant needed by weighing, raw material is: MgO or MgCO 3 One or a mixture of two, Al 2 o 3 or Al 2 (CO 3 ) 3 One or a mixture of two, MnO 2 , Mn(CO 3 ) 2 or Mn(NO 3 ) 2 one or a mixture of several. Put the required raw materials in an oven to fully dry, add a certain amount of absolute ethanol, the ratio of the volume of absolute ethanol to the mass of all reactants is 1-2mL: 1g, in order to make the reaction fully, add 5-10% by weight to the raw materials Ratio of co-solvent H 3 BO 3 . Then grind and mix evenly, place the obtained grinding mixture in a muffle furnace, first burn it for the first time, the burning temperature is 400°C, and the time is 0.5-2 hours, after cooling, grind and pulverize the obtained material; Put it back in the muffle furnace for the second burning, the tempe...

Embodiment 3

[0049] Embodiment 3 prepares Mg 4 Al 14 o 25 :xMn 4+ Luminescent material

[0050] The preparation method is the same as in Example 2, the difference is that the weight is based on Mg 4 Al 14 o 25 :xMn 4+ (x=0.002, 0.004, 0.006, 0.008, 0.015, 0.02), respectively prepared composite aluminate red luminescent materials with different manganese content.

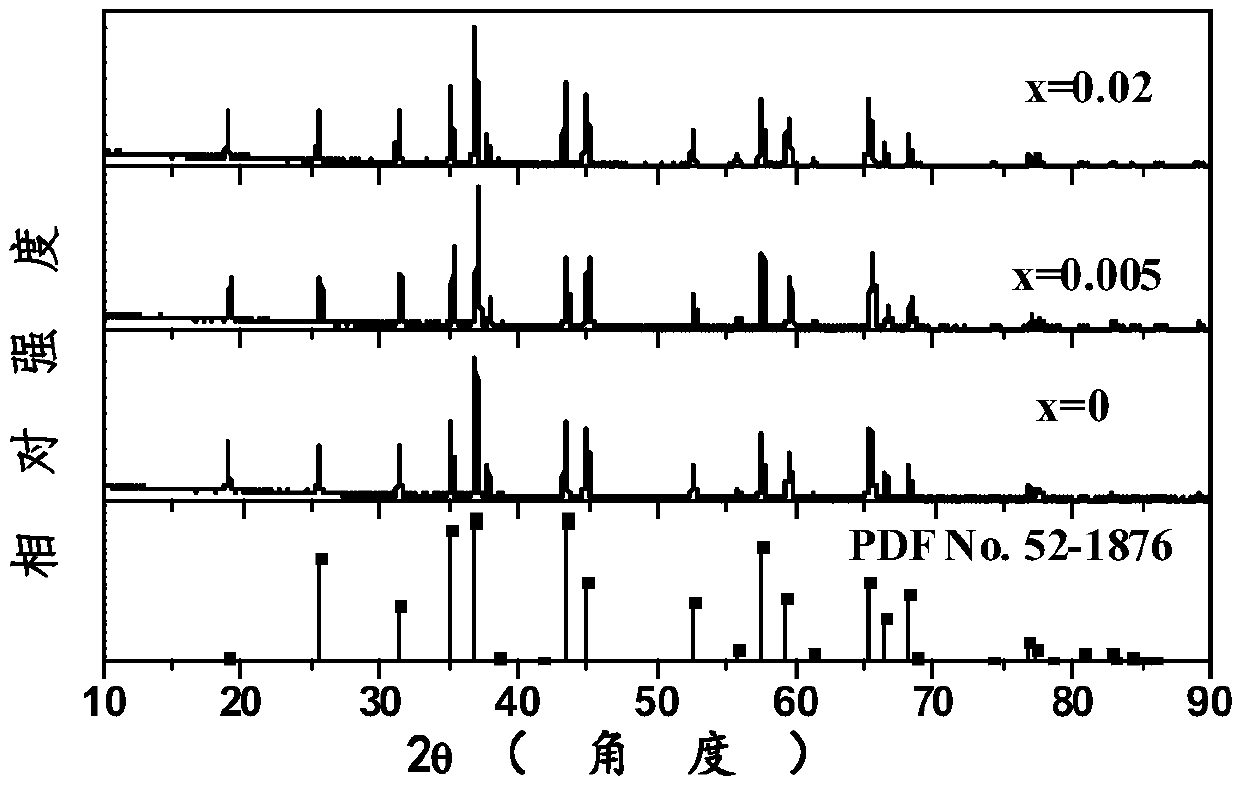

[0051] Carry out XRD analysis to the product when x=0.02 in embodiment 1, embodiment 2 and embodiment 3, see image 3 ,From image 3 It can be seen that the material obtained by our synthesis and the standard Mg 4 Al 14 o 25 The diffraction peaks are in good agreement, indicating that the synthesis of single-phase Mg 4 Al 14 o 25 Phosphor. It was identified as Mn by XRD analysis 4+ Doped with Mg 4 Al 14 o 25 Single crystal powder, the crystal belongs to the orthorhombic crystal system, and the unit cell parameters are α=β=γ=90°.

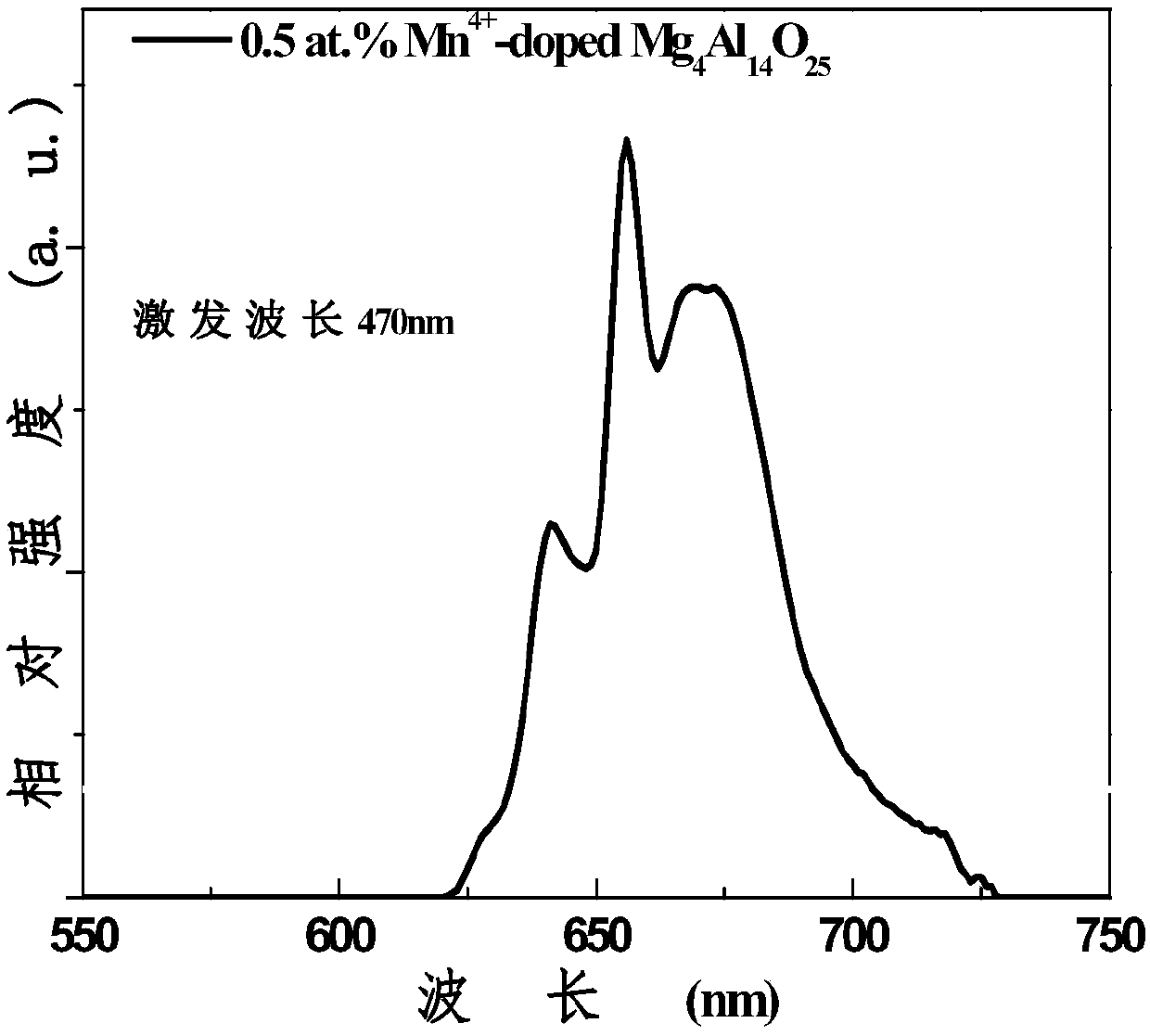

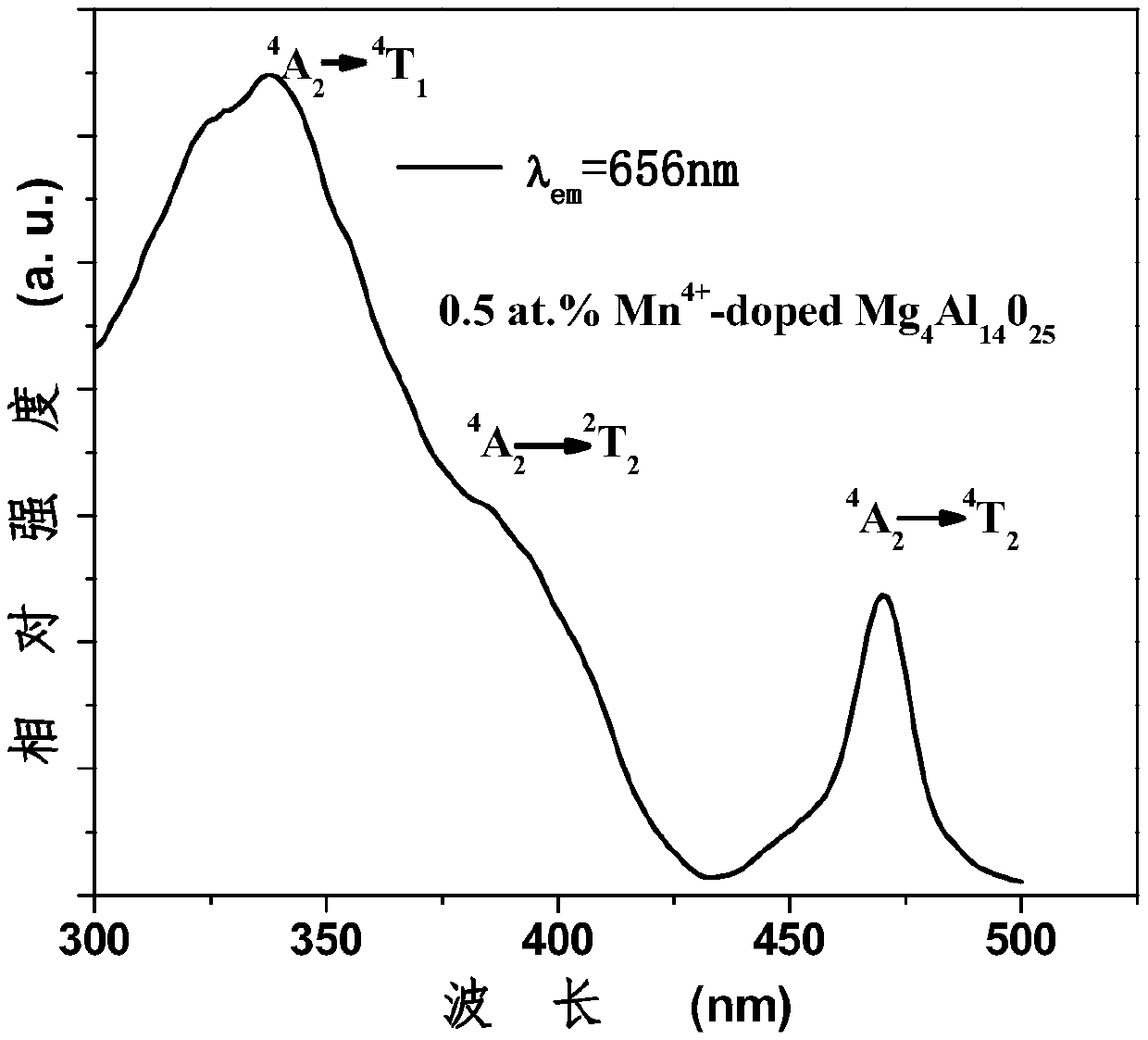

[0052] Relationship Between Fluorescence Emission Spectral Intensity and Dop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com