A method for detecting hydrazine hydrate

A technology of hydrazine hydrate and detection solution, which is applied in the measurement of color/spectral characteristics, material analysis by observing the influence on chemical indicators, and analysis by making materials undergo chemical reactions, etc., which can solve the complex, time-consuming, and Unable to realize rapid and trace detection of hydrazine hydrate and other problems, to achieve the effect of simple and fast operation and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of detection solution: Add 3 mg of elemental sulfur powder to 3 mL of NMP and stir with a magnetic force at 500 r / min for 10 minutes to obtain a detection solution;

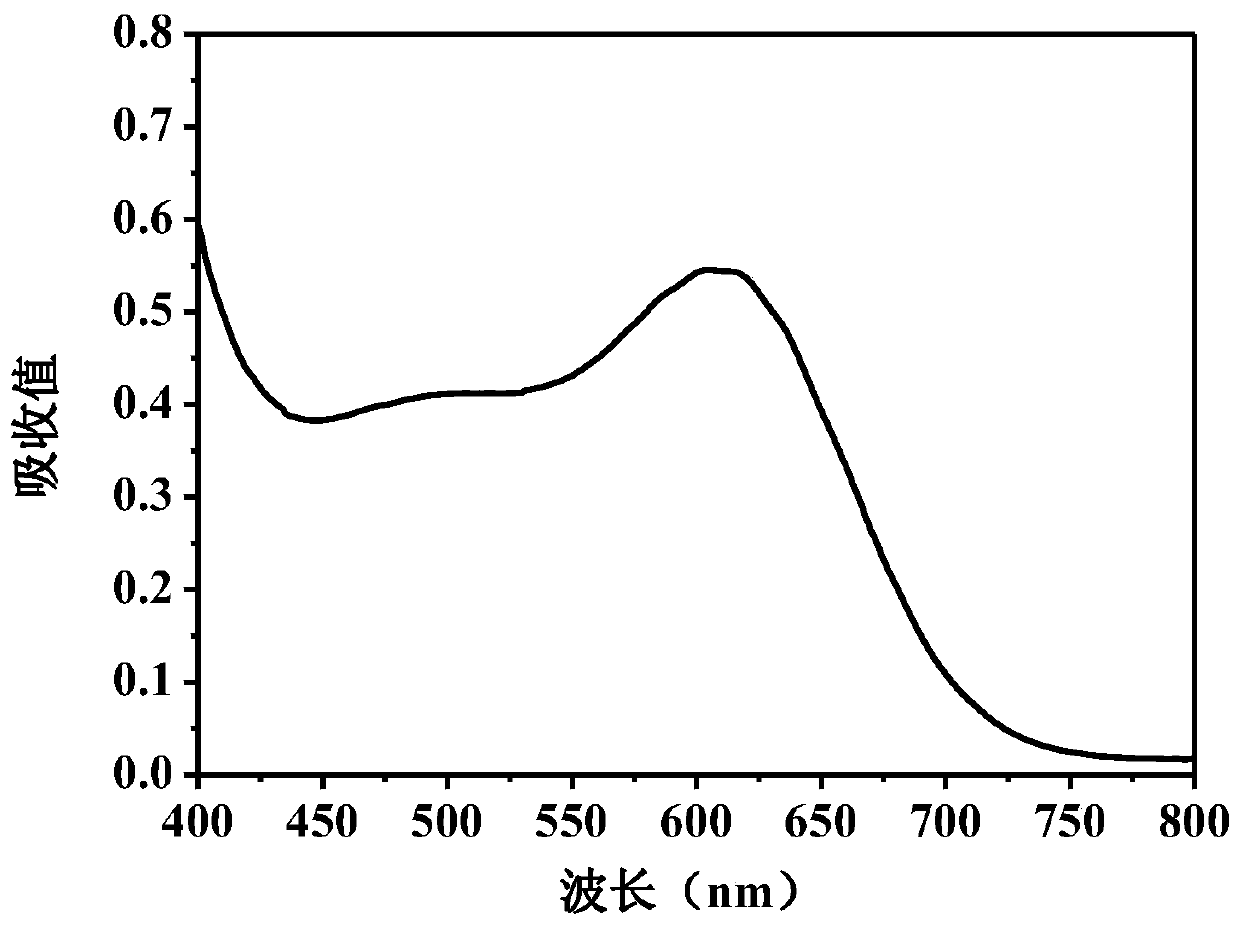

[0034] (2) Add 100ul of 0.1wt% hydrazine hydrate aqueous solution to the detection solution, stir it magnetically at 500r / min, observe the color change of the solution during the stirring process, and immediately (within 30s) carry out ultraviolet light on the solution after the mixed solution turns blue. Visible light detection, the results are as follows figure 1 , Figure 5 shown;

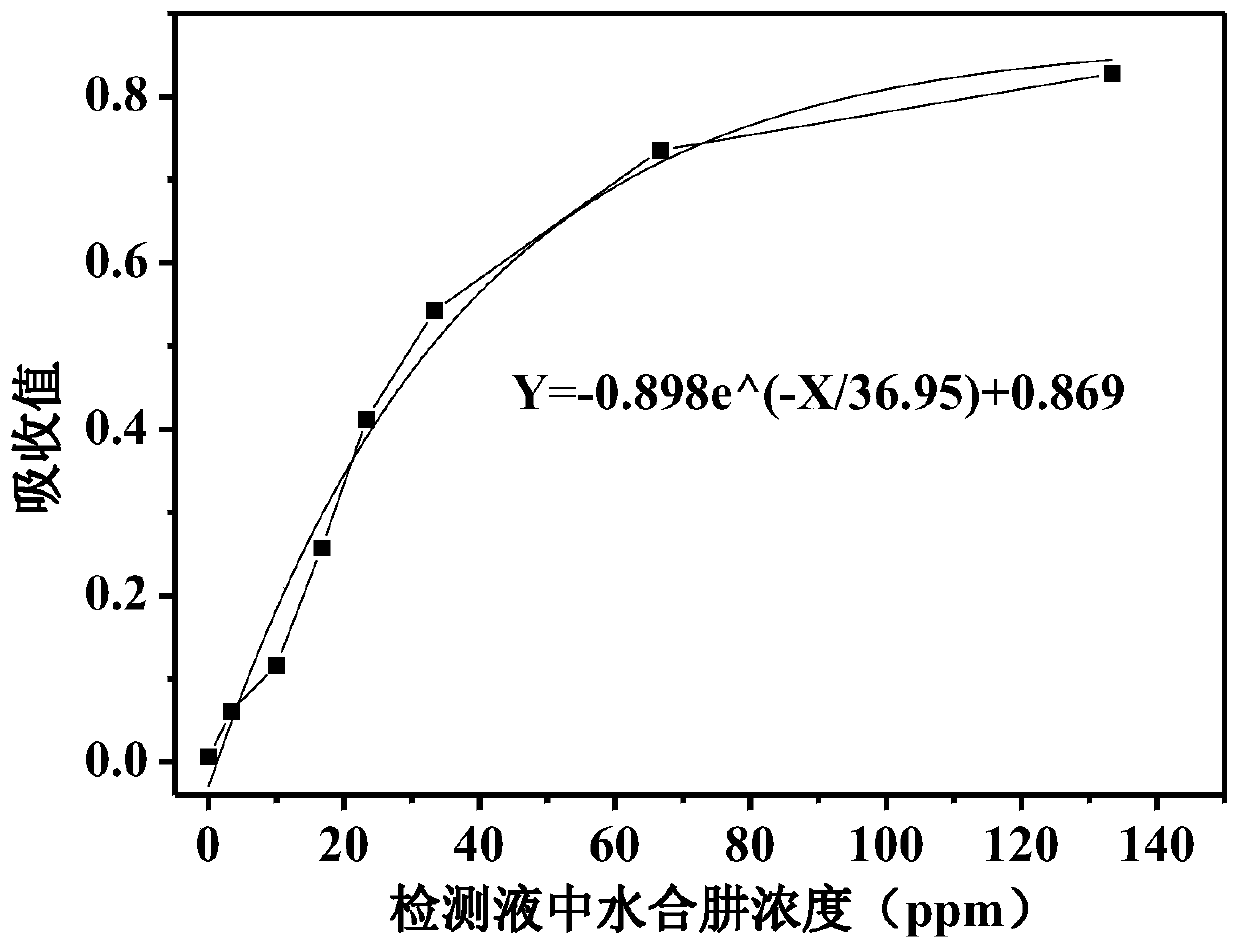

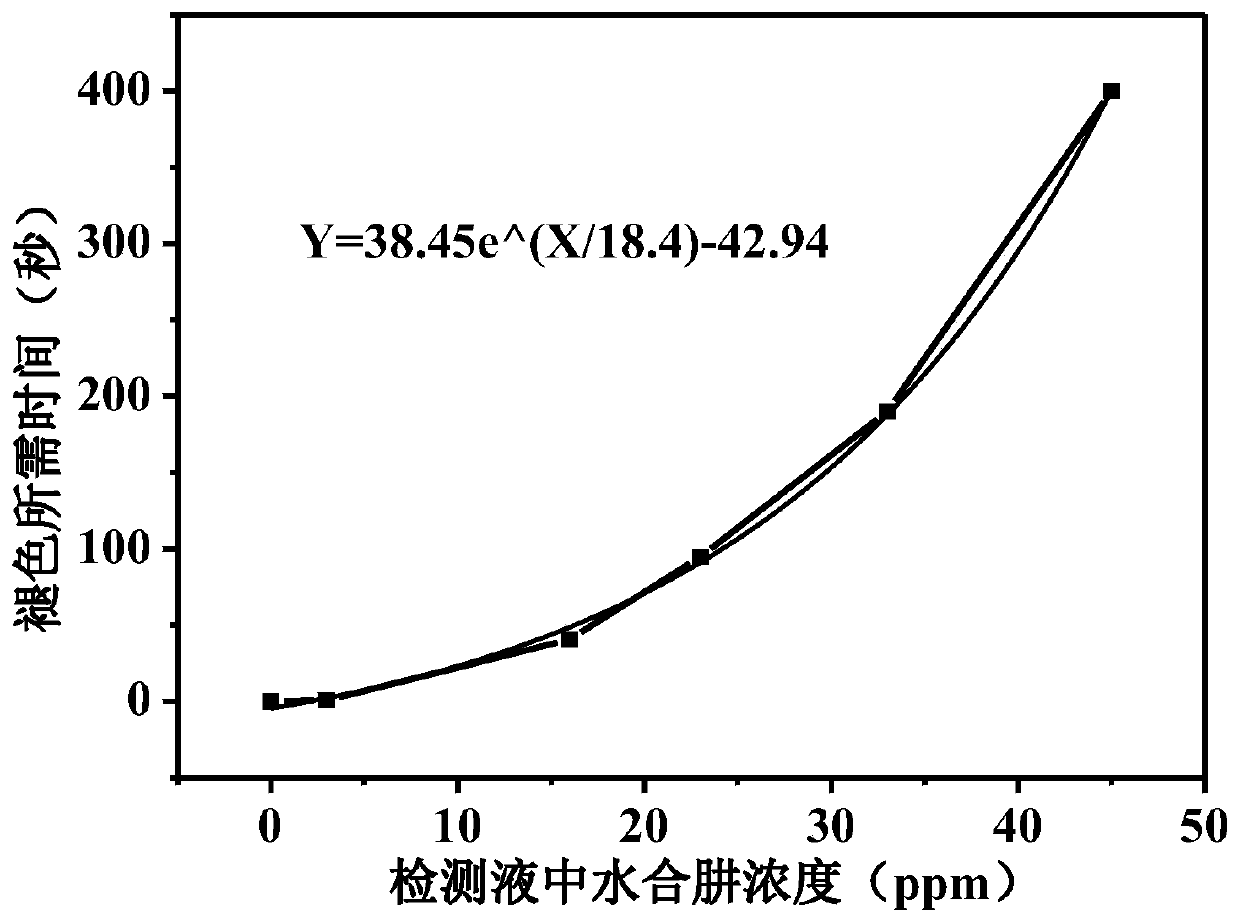

[0035] (3) Add different volumes of 0.1wt% hydrazine hydrate aqueous solution to the detection solution, stir with 500r / min magnetic force, observe the color change of the solution during the stirring process, and immediately (within 30s) test the solution after the mixed solution turns blue. UV-visible light detection, and the function plot of the peak value of the absorption peak and the amount of hydrazi...

Embodiment 2

[0039] (1) Preparation of detection solution: Add 3 mg of elemental sulfur powder into 3 mL of DMF and stir with a magnetic force at 500 r / min for 10 minutes to obtain a mixed detection solution;

[0040] (2) Add 10ul of 0.1wt% hydrazine hydrate aqueous solution to the detection solution, stir it magnetically at 500r / min, observe the color change of the solution during the stirring process, and immediately (within 30s) carry out ultraviolet light on the solution after the mixed solution turns blue. Visible light detection, the results are as follows Figure 4 shown.

Embodiment 3

[0042] (1) Preparation of detection solution: Add 3 mg of elemental sulfur powder to 3 mL of DMA with magnetic stirring at 500 r / min and mix for 10 minutes to obtain a mixed detection solution

[0043] (2) Add 10ul of 0.1wt% hydrazine hydrate aqueous solution to the detection solution, stir it magnetically at 500r / min, observe the color change of the solution during the stirring process, and immediately (within 30s) carry out ultraviolet light on the solution after the mixed solution turns blue. Visible light detection, the results are as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com