A kind of skin moisturizing agent based on liquid natural rubber and preparation method thereof

A natural rubber and humectant technology, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve problems such as unsatisfactory moisturizing effect, short moisturizing time, and difficulty in maintaining oil film for a long time, and achieve Good for skin moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

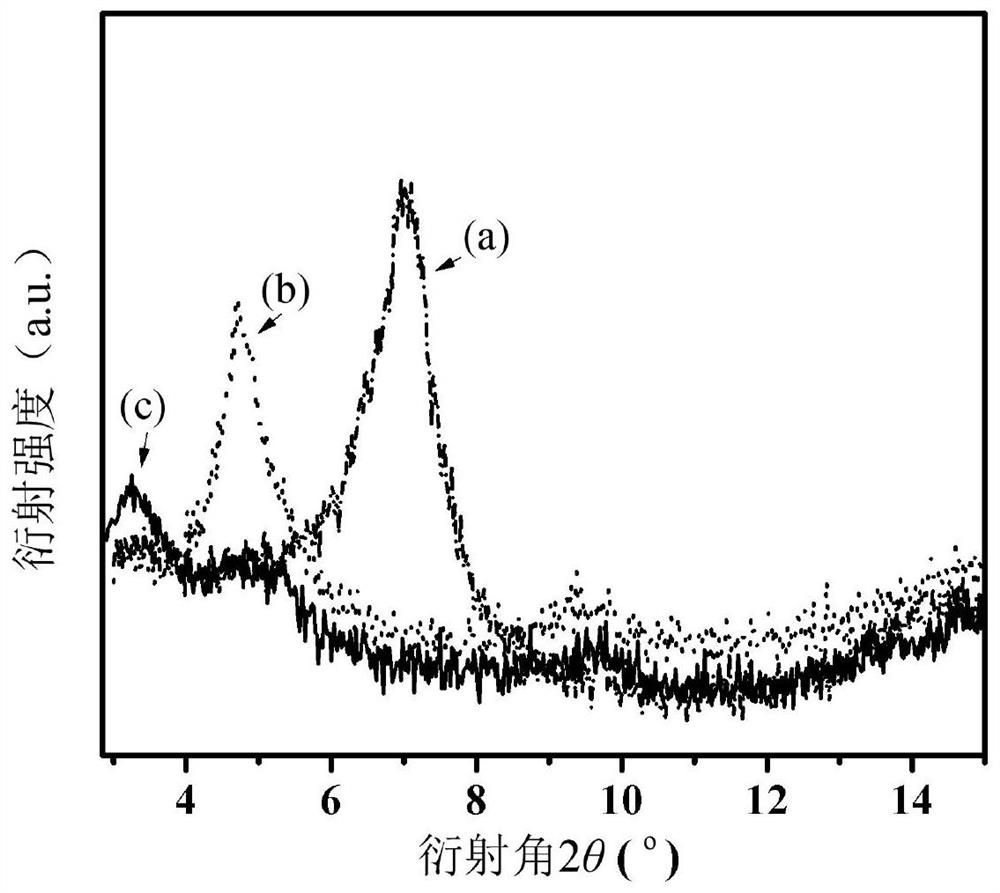

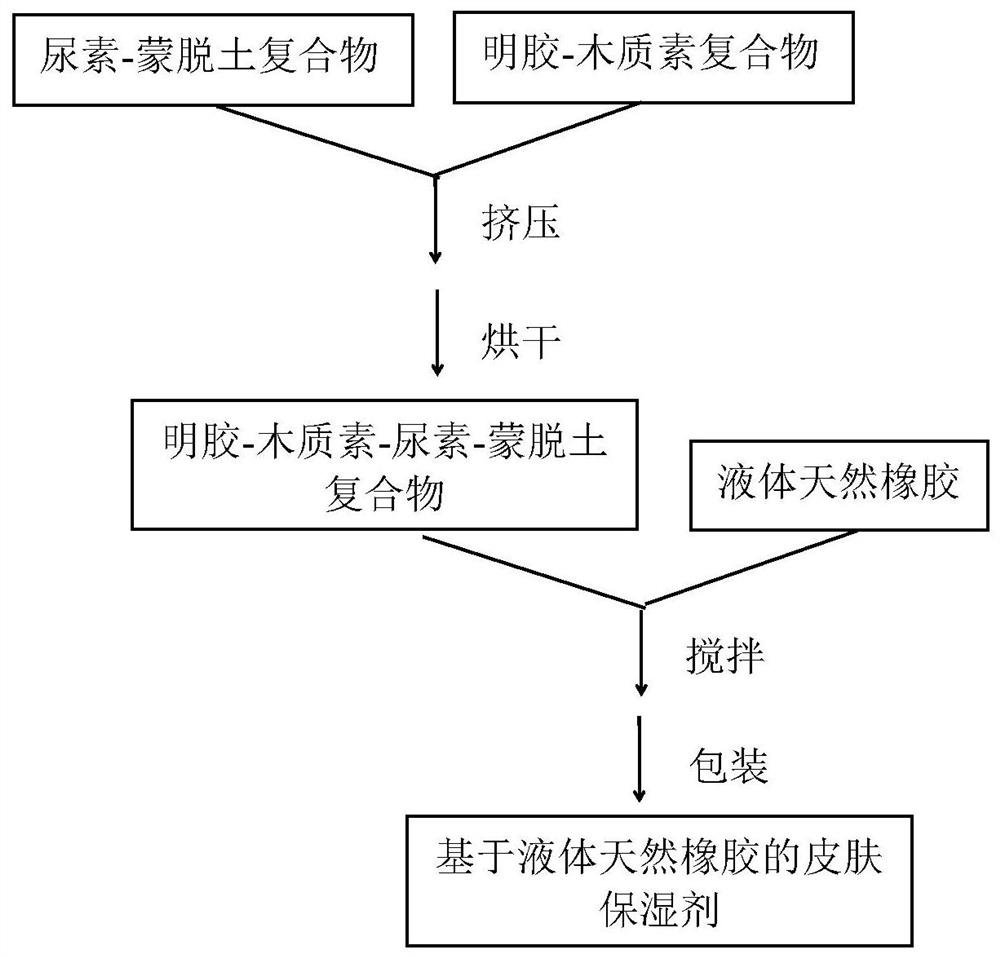

[0037] (1) Add sodium-based montmorillonite, urea and appropriate amount of water into the container in turn, mix and stir at room temperature to form a slurry mixture, wherein the weight ratio of montmorillonite, urea and water is 1:5:2;

[0038] (2) The muddy mixture obtained in step (1) is repeatedly extruded 15 times through an extruder at room temperature to prepare a urea-montmorillonite paste compound, and the urea-montmorillonite paste compound is placed in In an oven, dry at a temperature of 60°C for 24 hours, and grind it into a 300-mesh urea-montmorillonite composite solid powder;

[0039] (3) adding lignin, gelatin and appropriate amount of water to the container in turn, mixing and stirring at room temperature to form a gelatin-lignin colloidal compound, wherein the weight ratio of gelatin, lignin and water is 1:10:5;

[0040] (4) the urea-montmorillonite composite solid powder obtained in step (2) and the gelatin-lignin colloidal compound obtained in step (3) are...

Embodiment 2

[0044] (1) Add sodium-based montmorillonite, urea and appropriate amount of water to the container in turn, mix and stir at room temperature to form a slurry mixture, wherein the weight ratio of montmorillonite, urea and water is 1:4:1.7;

[0045] (2) The muddy mixture obtained in step (1) is repeatedly extruded 13 times through an extruder at room temperature to prepare a urea-montmorillonite paste compound, and the urea-montmorillonite paste compound is placed in In an oven, dry at a temperature of 70°C for 22 hours, and grind it into a 400-mesh urea-montmorillonite composite solid powder;

[0046] (3) adding lignin, gelatin and appropriate amount of water to the container in turn, mixing and stirring at room temperature to form a gelatin-lignin colloidal compound, wherein the weight ratio of gelatin, lignin and water is 1:12:10;

[0047] (4) the urea-montmorillonite composite solid powder obtained in step (2) and the gelatin-lignin colloidal compound obtained in step (3) ar...

Embodiment 3

[0051] (1) Add sodium-based montmorillonite, urea and appropriate amount of water to the container in turn, mix and stir at room temperature to form a slurry mixture, wherein the weight ratio of montmorillonite, urea and water is 1:3:1.5;

[0052] (2) The muddy mixture obtained in step (1) is repeatedly extruded 12 times through an extruder at room temperature to prepare a urea-montmorillonite paste compound, and the urea-montmorillonite paste compound is placed in In an oven, dry at a temperature of 90°C for 15 hours, and grind it into a 300-mesh urea-montmorillonite composite solid powder;

[0053] (3) adding lignin, gelatin and appropriate amount of water to the container in turn, mixing and stirring at room temperature to form a gelatin-lignin colloidal compound, wherein the weight ratio of gelatin, lignin and water is 1:17:20;

[0054] (4) the urea-montmorillonite composite solid powder obtained in step (2) and the gelatin-lignin colloidal compound obtained in step (3) ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com