A kind of reduced graphene oxide antibacterial dressing and preparation method thereof

A graphene and antibacterial layer technology, applied in the field of reduced graphene oxide antibacterial dressings and its preparation, can solve the problems of low antibacterial activity, unfavorable wound healing, poor biocompatibility, etc., achieve good antibacterial effect, easy dressing change, The effect of promoting repair and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

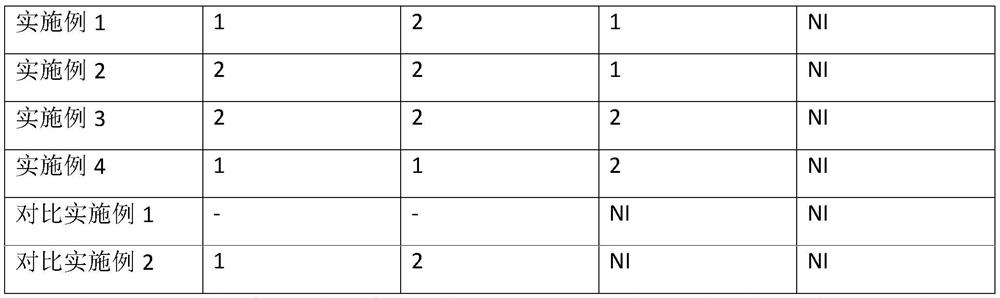

Examples

Embodiment 1

[0045] Adding 1 part by mass of graphene oxide to deionized water to form a 1 g / L graphene oxide dispersion, adding 5 parts by mass of ascorbic acid, stirring and reacting for 12-24 hours, filtering and drying to obtain reduced graphene oxide;

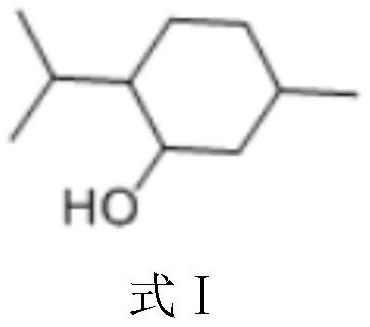

[0046]Take 1 mass part of reduced graphene oxide and dissolve it in dimethylformamide, add 1 mass part of menthol, react with microwave power 400W for 2 hours, and obtain the reduced graphene oxide-menthol compound after separation and purification;

[0047] Reduced graphene oxide-menthol complex at 15g / m 2 Spray evenly on the gauze, UV 200J / m 2 It was activated by irradiation for 48 hours to obtain an antibacterial layer.

[0048] The base layer is combined with the antibacterial layer, and the reduced graphene oxide antibacterial dressing is obtained after cutting, shaping and disinfection.

Embodiment 2

[0050] 1 mass part of graphene oxide is added to deionized water to form a 6g / L graphene oxide dispersion, 10 mass parts of hydrazine hydrate is added, stirred and reacted for 12 hours, filtered and dried to obtain reduced graphene oxide;

[0051] Take 1 mass part of reduced graphene oxide and dissolve it in DMSO, add 10 mass parts of menthol, and react with a microwave power of 700W for 0.5 hours, and obtain the reduced graphene oxide-menthol complex after separation and purification;

[0052] Reduced graphene oxide-menthol complex at 10g / m 2 The amount of coating on the gauze, UV 500J / m 2 It was activated by irradiation for 30 hours to obtain an antibacterial layer.

[0053] The base layer is combined with the antibacterial layer, and the reduced graphene oxide antibacterial dressing is obtained after cutting, shaping and disinfection.

Embodiment 3

[0055] 1 mass part of graphene oxide is added to deionized water to form a 10g / L graphene oxide dispersion, 8 mass parts of ascorbic acid are added, stirred and reacted for 15 hours, filtered and dried to obtain reduced graphene oxide;

[0056] Take 1 mass part of reduced graphene oxide and dissolve it in dimethylformamide, add 8 mass parts of menthol, and react for 1 hour at a microwave power of 560W, and obtain a reduced graphene oxide-menthol compound after separation and purification;

[0057] Reduced graphene oxide-menthol complex at 12g / m 2 The amount of coating on the gauze, UV 800J / m 2 It was activated by irradiation for 36 hours to obtain an antibacterial layer.

[0058] The base layer is combined with the antibacterial layer, and the reduced graphene oxide antibacterial dressing is obtained after cutting, shaping and disinfection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com