Nano-composite mycotoxin adsorbent, preparation method thereof and application of adsorbent

A technology of toxin adsorbent and composite mold, applied in the direction of selective adsorption, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of increasing heavy metal content, large formula space, polluting feed, etc., achieve low dosage and release immune suppression , the effect of good cation exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

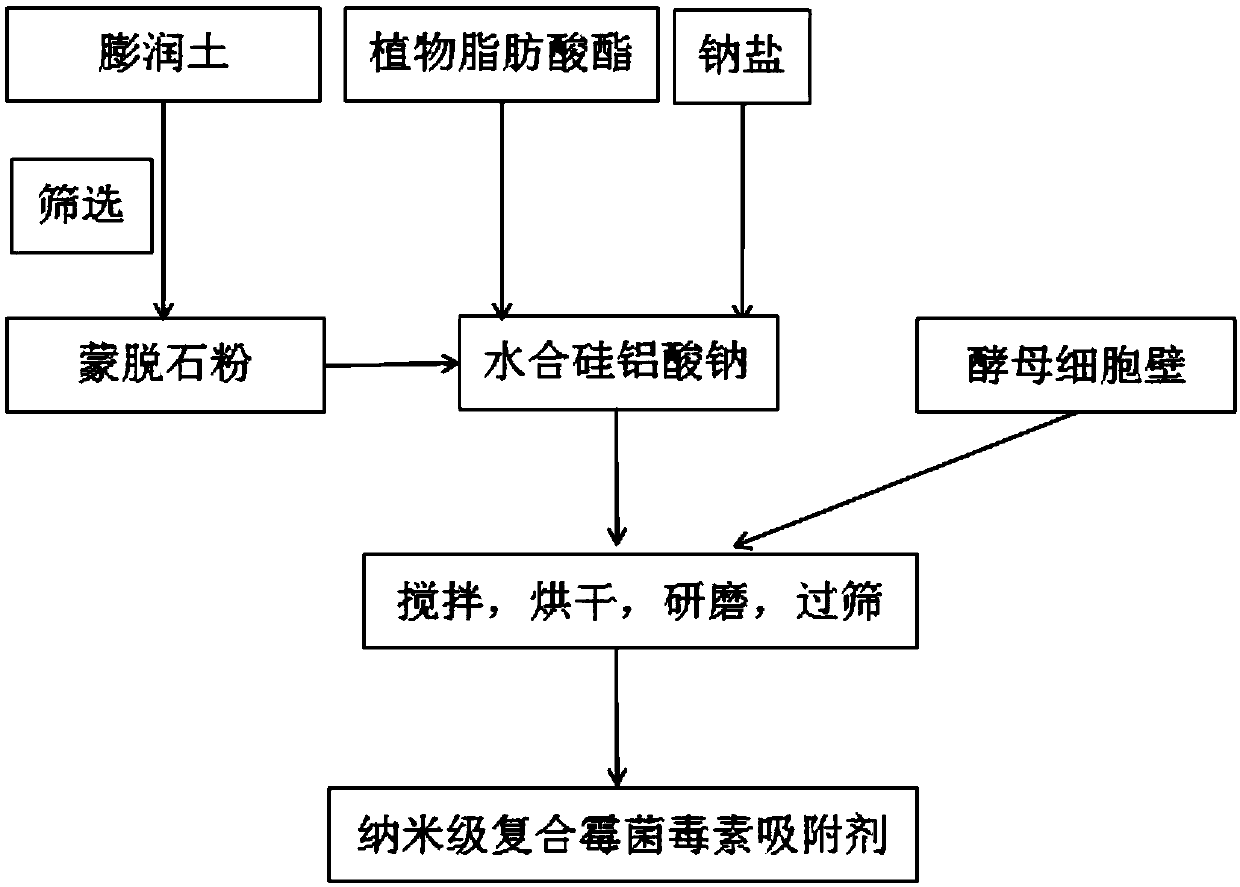

[0029] The preparation method of the above nano-scale composite mycotoxin adsorbent is as follows: mix montmorillonite powder, sodium salt, and vegetable fatty acid ester evenly, then heat for activation, reaction and extrusion kneading, add yeast cell wall, extrude after stirring, and bake Dried, ground, sieved, that is.

[0030] Such as figure 1 As shown, the above-mentioned preparation method specifically comprises the following steps:

[0031] a, bentonite raw soil is made into montmorillonite powder by winnowing purification method;

[0032] b. After adding water to the montmorillonite powder to make it wet, add sodium salt and stir evenly before starting to heat up;

[0033] c. When the temperature rises to 60-80°C, add vegetable fatty acid ester for extrusion activation, continue to heat up to 80-90°C and react for 0.5-1.5h to obtain hydrated sodium aluminosilicate;

[0034] d, mixing sodium aluminosilicate hydrate and yeast cell wall and stirring evenly to prepare a...

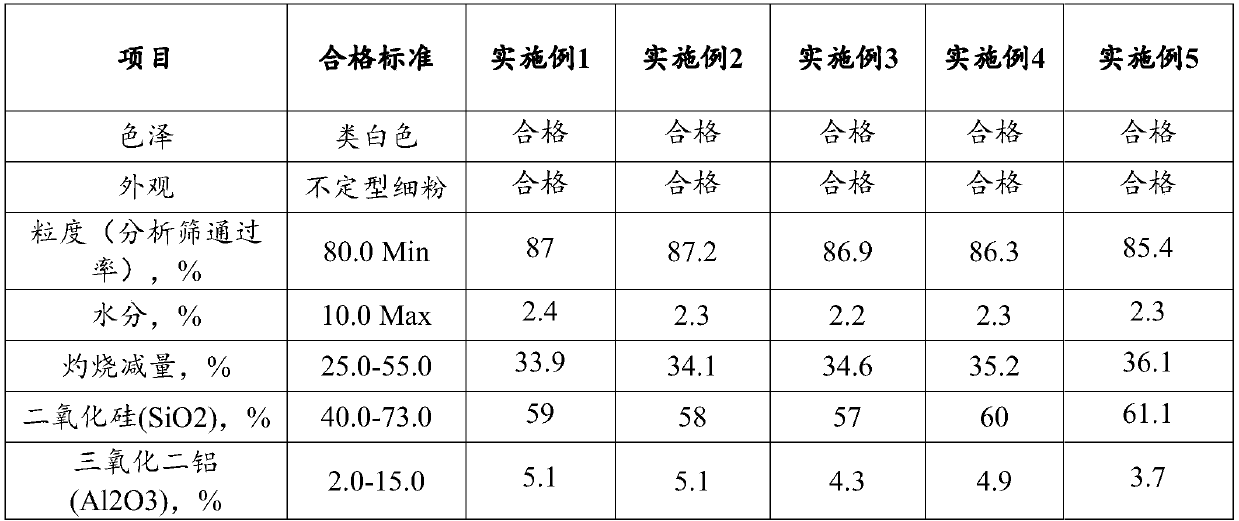

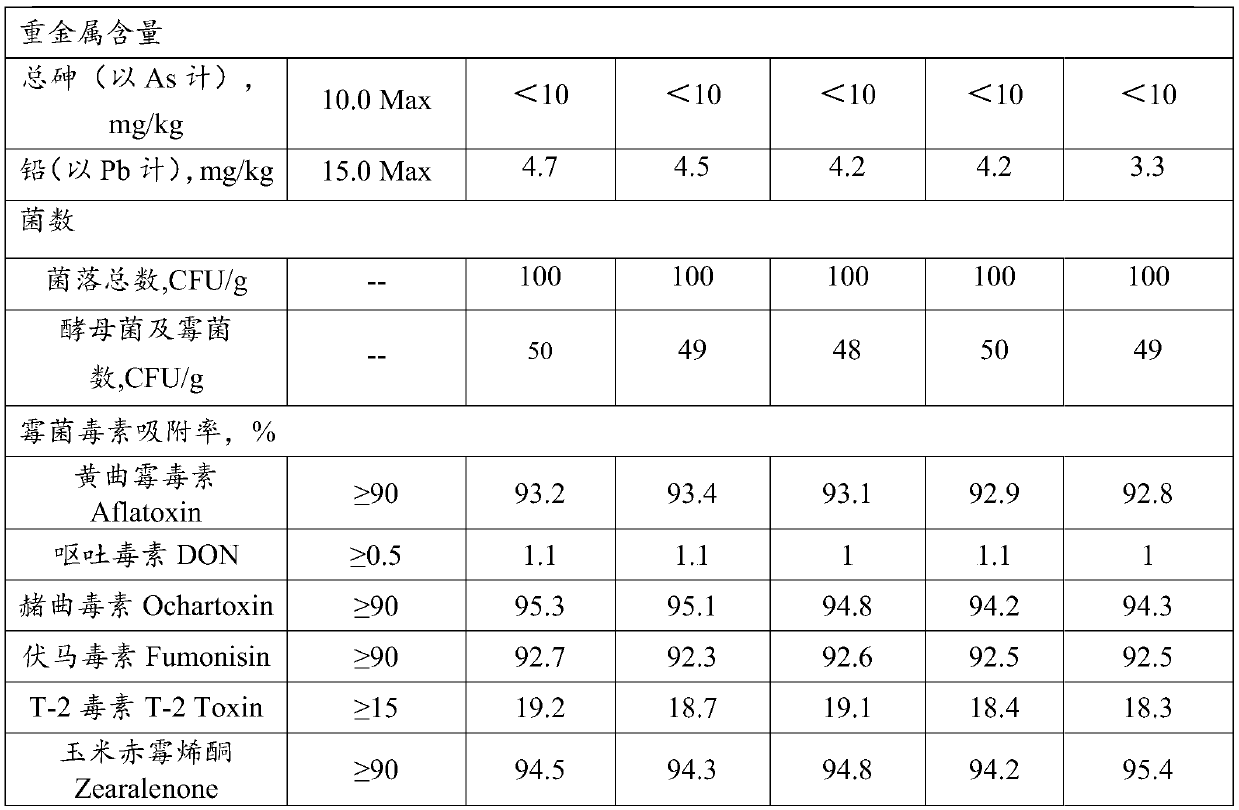

Embodiment 1

[0038] A nanoscale composite mycotoxin adsorbent comprises the following components in mass percentage: 55% of montmorillonite powder, 25% of vegetable fatty acid ester, 10% of anhydrous sodium carbonate, and 10% of yeast cell wall.

[0039] The small-scale preparation method of the nanoscale composite mycotoxin adsorbent described above comprises the following steps:

[0040] a, bentonite raw soil is made into montmorillonite powder by winnowing purification method;

[0041] b. After adding water to the montmorillonite powder to make it wet, add anhydrous sodium carbonate and stir evenly before starting to heat up;

[0042] c. When the temperature rises to 70°C, add vegetable fatty acid ester for extrusion activation, continue to heat up to 90°C and react for 1 hour to obtain hydrated sodium aluminosilicate;

[0043] d, mixing sodium aluminosilicate hydrate and yeast cell wall and stirring evenly to prepare a mixture;

Embodiment 2

[0046] A nanoscale composite mycotoxin adsorbent comprises the following components in mass percentage: 50% of montmorillonite powder, 30% of vegetable fatty acid ester, 10% of sodium chloride and 10% of yeast cell wall.

[0047] The small-scale preparation method of the nanoscale composite mycotoxin adsorbent described above comprises the following steps:

[0048] a, bentonite raw soil is made into montmorillonite powder by winnowing purification method;

[0049] b. After adding water to the montmorillonite powder to make it wet, add sodium chloride and stir evenly before starting to heat up;

[0050] c. When the temperature rises to 80°C, add vegetable fatty acid ester for extrusion activation, continue to heat up to 90°C and react for 1 hour to obtain hydrated sodium aluminosilicate;

[0051] d, mixing sodium aluminosilicate hydrate and yeast cell wall and stirring evenly to prepare a mixture;

[0052] e. Dry, grind, and sieve the mixture prepared in step d at 80° C., and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap