Method for efficiently and rapidly removing protein and pigment from the polysaccharide extract of Acanthopanax polysaccharides

A technology of Acanthopanax polysaccharide and extract, applied in the field of extraction and purification of natural products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1) Grind the dried orangiosus bark, pass through a 60-mesh sieve, add 95% volume fraction of ethanol solution to the sieved coarse powder according to the ratio of 1g:10ml to liquid, reflux at 40°C for 1 hour, and remove the fat and other components, filtered under reduced pressure, the ethanol solvent in the filter cake was evaporated to dryness, and the powder was recovered for later use.

[0067] 2) Mix the degreased dry Antsotosa powder with deionized water at a ratio of 1g:12ml, soak at 60°C for 4h, and then perform reflux extraction twice at 95°C for 15min. Combine and collect the extracts for 60 minutes each time; centrifuge at 8000 rpm for 20 minutes, collect the supernatant and concentrate in vacuum to the same weight as the original medicinal material, add 4.5 times the volume of 95% ethanol to the concentrated filtrate, carry out alcohol precipitation at room temperature for 24 hours, and filter with suction , the supernatant after alcohol precipitation is co...

Embodiment 2

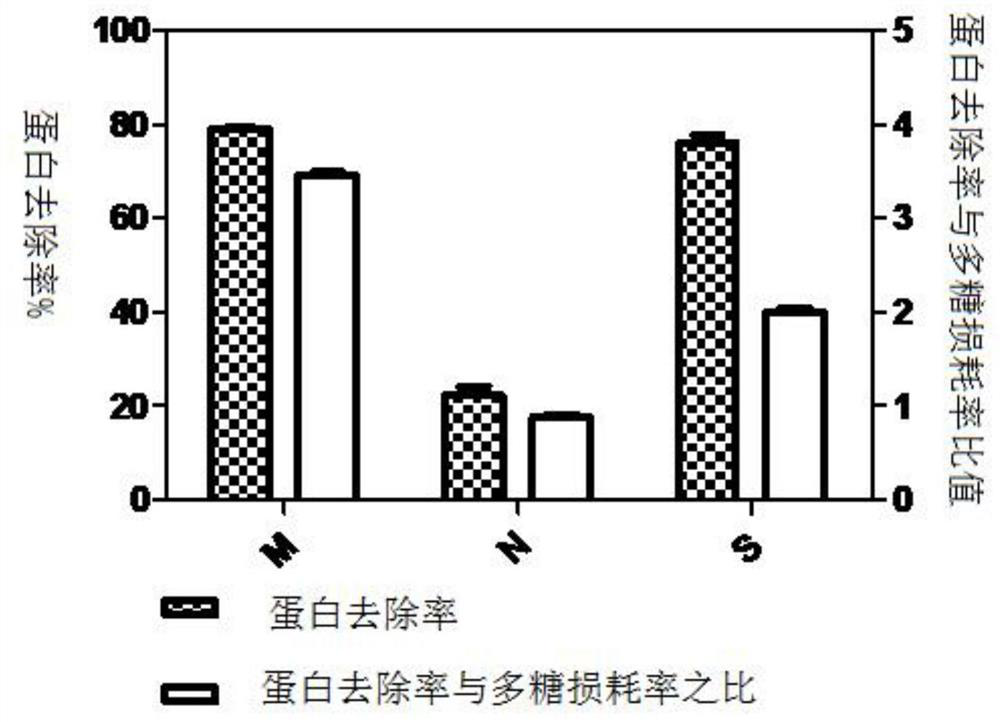

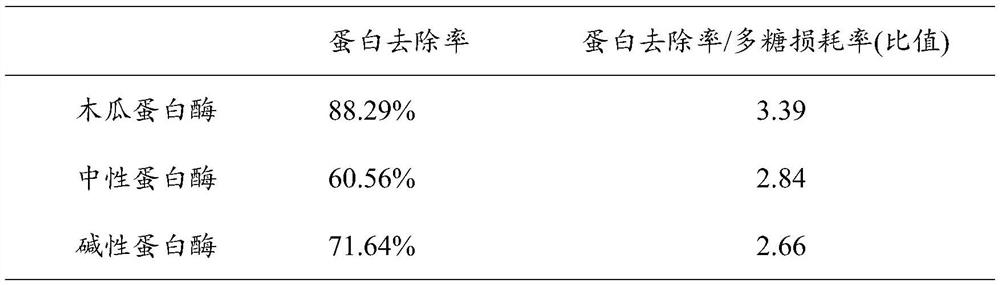

[0075] Comparison of Protein Removal Efficiency of Different Proteases

[0076] Add papain, neutral protease and alkaline protease of the same activity unit respectively, carry out under enzymatic reaction conditions, other conditions are all carried out according to embodiment 1 step, calculate the egg removal rate under each ratio and the retention rate of polysaccharide, the result See Table 1.

[0077] The comparison of different proteases in table 1 to protein removal rate

[0078]

[0079] As can be seen from Table 1, under the same amount of enzymes, papain has the best deproteinization effect, with a protein removal rate of 88.29%; followed by alkaline protease, with a protein removal rate of 71.64%; neutral protease deproteinization The effect is not ideal. Considering the ratio of protein removal rate to polysaccharide loss rate among the three, papain was the best.

Embodiment 3

[0081] Effect of enzymatic hydrolysis time on protein removal rate

[0082] According to the method of Example 1, the enzymolysis time was adjusted to 0.5-3.5h, and other conditions were kept constant, and the protein and pigment removal rate and polysaccharide retention rate were calculated at each enzymolysis time. The results showed that the protein removal rate increased rapidly within 2 hours with the prolongation of enzymatic hydrolysis time, reached a regional peak at 1.5-2 hours, and showed a downward trend after 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com