A kind of modified alkyd resin and preparation method thereof

A kind of alkyd resin, modified technology, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems of affecting hard drying, water resistance and hardness, cross-linking density reduction, slow drying speed, etc., to achieve high cost performance, resin viscosity reduction, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

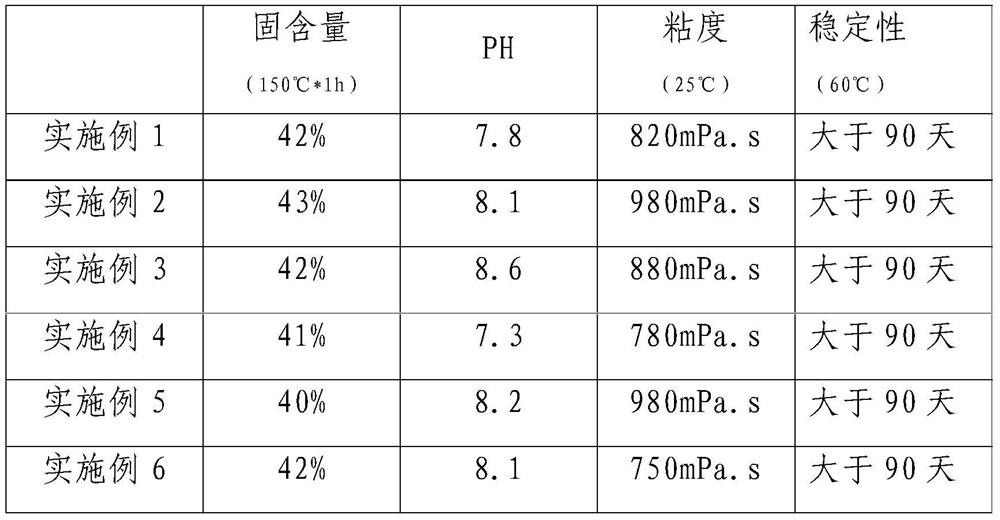

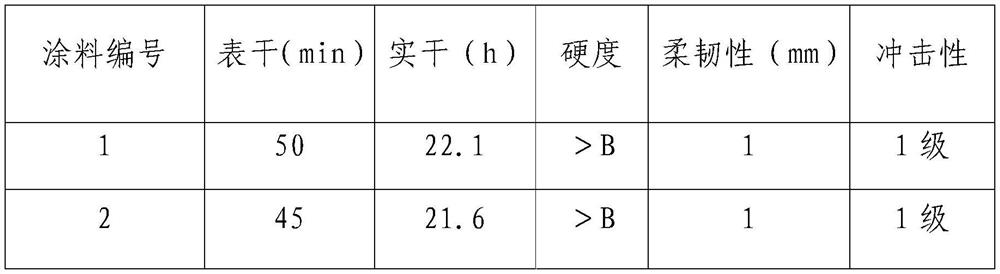

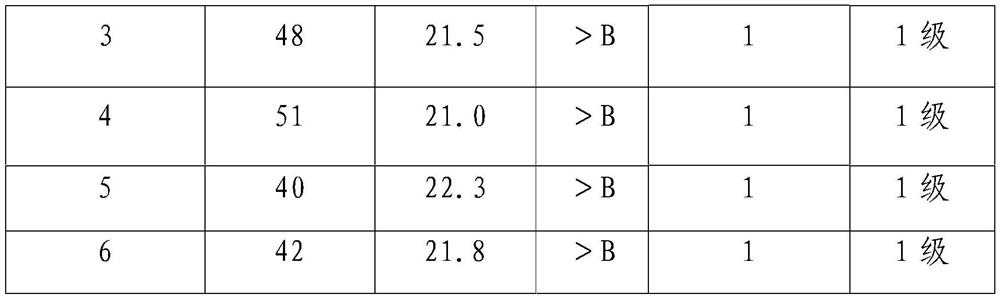

Examples

Embodiment 1

[0043] 16.5 parts of tall oleic acid, 1.9 parts of benzoic acid, 8.5 parts of isophthalic acid, 2.6 parts of trimethylolpropane, 4.8 parts of pentaerythritol and 1.2 parts of xylene were dehydrated and condensed at 220°C, and reacted into the reaction system When the acid value in the reaction system is 20mgKOH / g, cool the reaction system to 160°C, remove the xylene in the reaction system in a vacuum, then cool the reaction system to 100°C, and then add 15 parts of diethylene diethylene glycol to the reverse system Alcohol monobutyl ether and 10 parts of diethylene glycol monomethyl ether dilute the reaction system to obtain the basic alkyd resin;

[0044] Divide the obtained basic alkyd resin into two parts A and B of equal mass.

[0045] Raise the temperature of the basic alkyd resin of part A to 130 ° C, within 3 hours, add 9.5 parts of styrene, 3.5 parts of methyl methacrylate, 0.5 parts of butyl acrylate, 2.5 parts of cyclohexanediol monoacrylate, 0.7 parts of benzene per...

Embodiment 2

[0048] Put 16.5 parts of a mixture of soybean oil and linolenic acid, 1.9 parts of benzoic acid, 8.5 parts of isophthalic acid, 6.8 parts of pentaerythritol, and 1.2 parts of xylene in a reaction vessel, and carry out a dehydration condensation reaction at 200°C to the system After the acid value is 18mgKOH / g, the reaction system is cooled to 160°C, the xylene in the reaction system is removed in vacuum, and then the temperature is lowered to 100°C, and 15 parts of diethylene glycol monobutyl ether and 10 parts of diethylene glycol dimethyl ether, dilute reaction system, obtain basic alkyd resin;

[0049] Divide the obtained basic alkyd resin into two parts A and B of equal mass.

[0050] Raise the temperature of the basic alkyd resin of part A to 135°C, and within 3 hours, add a mixture of 13.5 parts of styrene, 2.5 parts of cyclohexanediol monoacrylate, 0.65 parts of benzoyl peroxide, and 0.1 parts of tert-butyl peroxybenzoate Add it dropwise to the reaction system, and kee...

Embodiment 3

[0053] Put 15.0 parts of soybean oleic acid, 3 parts of benzoic acid, 8.5 parts of isophthalic acid, 6.8 parts of pentaerythritol, and 1.2 parts of xylene in a reaction vessel, and carry out dehydration condensation reaction at 170°C until the acid value is 16 mgKOH / g , the temperature of the reaction system was lowered to 160°C, the xylene was removed in vacuum, and then the temperature was lowered to 100°C, and then 15 parts of diethylene glycol monobutyl ether, 8 parts of propylene glycol monobutyl ether and 2 parts of dipropylene glycol monobutyl ether were added to the reverse system ether to dilute the reaction system to obtain the basic alkyd resin.

[0054] Divide the quality of the obtained basic alkyd resin into two parts, A and B.

[0055] Raise the temperature of the basic alkyd resin in part A to 130°C, within 3.5 hours, add 13 parts of styrene, 0.5 parts of butyl acrylate, 2.5 parts of cyclohexanediol monoacrylate, 0.65 parts of benzoyl peroxide and 0.1 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com