Nanomaterial composite flame-retardant engineering plastic preparation method

A technology of engineering plastics and composite flame retardant, which is applied in the field of preparation of nano-material composite flame retardant engineering plastics, can solve the problems of decreased flame retardant performance, inability to further improve mechanical properties, easy migration of flame retardants, etc., and increase the quantity , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

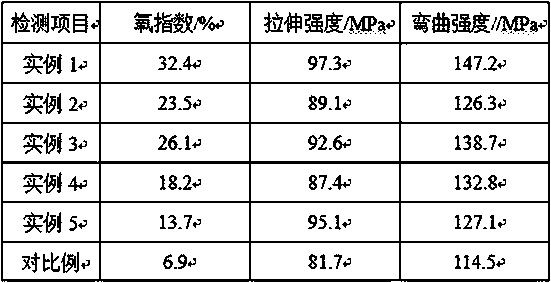

Examples

example 1

[0025]Mix the plant fiber and biogas liquid at a mass ratio of 1:10, let it stand and soak for 5 hours at room temperature, then transfer the soaked plant fiber into the steam explosion tank, and then pass saturated water vapor into the steam explosion tank , until the pressure in the steam explosion tank reaches 2.0 MPa, keep the pressure for 10 minutes, open the discharge valve of the steam explosion tank, spray the material in the steam explosion tank into the receiving container, and obtain the steam explosion slag; After freezing for 45s, transfer it to an extruder, and press it for 30 minutes under the condition of 20MPa to obtain the pressed material, then transfer the obtained pressed material into a vacuum drying oven, and vacuum dry it at a temperature of 85°C and a pressure of 80Pa. to a constant weight to obtain a dry press material; mix graphene oxide and water at a mass ratio of 1:18 and pour it into a beaker, and ultrasonically disperse it for 20 minutes at an ul...

example 2

[0027] Mix graphene oxide and water into a beaker at a mass ratio of 1:18, and ultrasonically disperse for 20 minutes at an ultrasonic frequency of 60 kHz, then add sodium polystyrene sulfonate that is 0.3 times the mass of graphene oxide into the beaker, And use a stirrer to stir and react at a speed of 400r / min for 60min to obtain a graphene oxide dispersion; after mixing the graphene oxide dispersion and a cobalt salt solution with a mass fraction of 8% at a mass ratio of 1:2, the ultrasonic frequency is 60kHz Under the condition of ultrasonic dispersion for 30 minutes, and then filtered to obtain a filter cake, and the obtained filter cake was dried to a constant weight at a temperature of 90 ° C to obtain pretreated graphene oxide; the pretreated graphene oxide was transferred to a tube furnace , and feed a reducing gas into the furnace at a rate of 300mL / min. Under the protection of the reducing gas, the temperature was programmed to rise to 550°C at a rate of 3°C / min. t...

example 3

[0029] Mix graphene oxide and water into a beaker at a mass ratio of 1:18, and ultrasonically disperse for 20 minutes at an ultrasonic frequency of 60 kHz, then add sodium polystyrene sulfonate that is 0.3 times the mass of graphene oxide into the beaker, And use a stirrer to stir and react at a speed of 400r / min for 60min to obtain a graphene oxide dispersion; after mixing the graphene oxide dispersion and a cobalt salt solution with a mass fraction of 8% at a mass ratio of 1:2, the ultrasonic frequency is 60kHz Under the condition of ultrasonic dispersion for 30 minutes, and then filtered to obtain a filter cake, and the obtained filter cake was dried to a constant weight at a temperature of 90 ° C to obtain pretreated graphene oxide; the pretreated graphene oxide was transferred to a tube furnace , and feed a reducing gas into the furnace at a rate of 300mL / min. Under the protection of the reducing gas, the temperature was programmed to rise to 550°C at a rate of 3°C / min. t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com