Method for jointly gasifying coal and heavy oil for preparing synthesis gas

A synthesis gas and co-gasification technology, applied in chemical instruments and methods, gasification process, granular/powdered fuel gasification, etc., can solve the problems of energy consumption and production cost reduction, large raw material consumption, synthesis gas output and energy efficiency Increased utilization etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

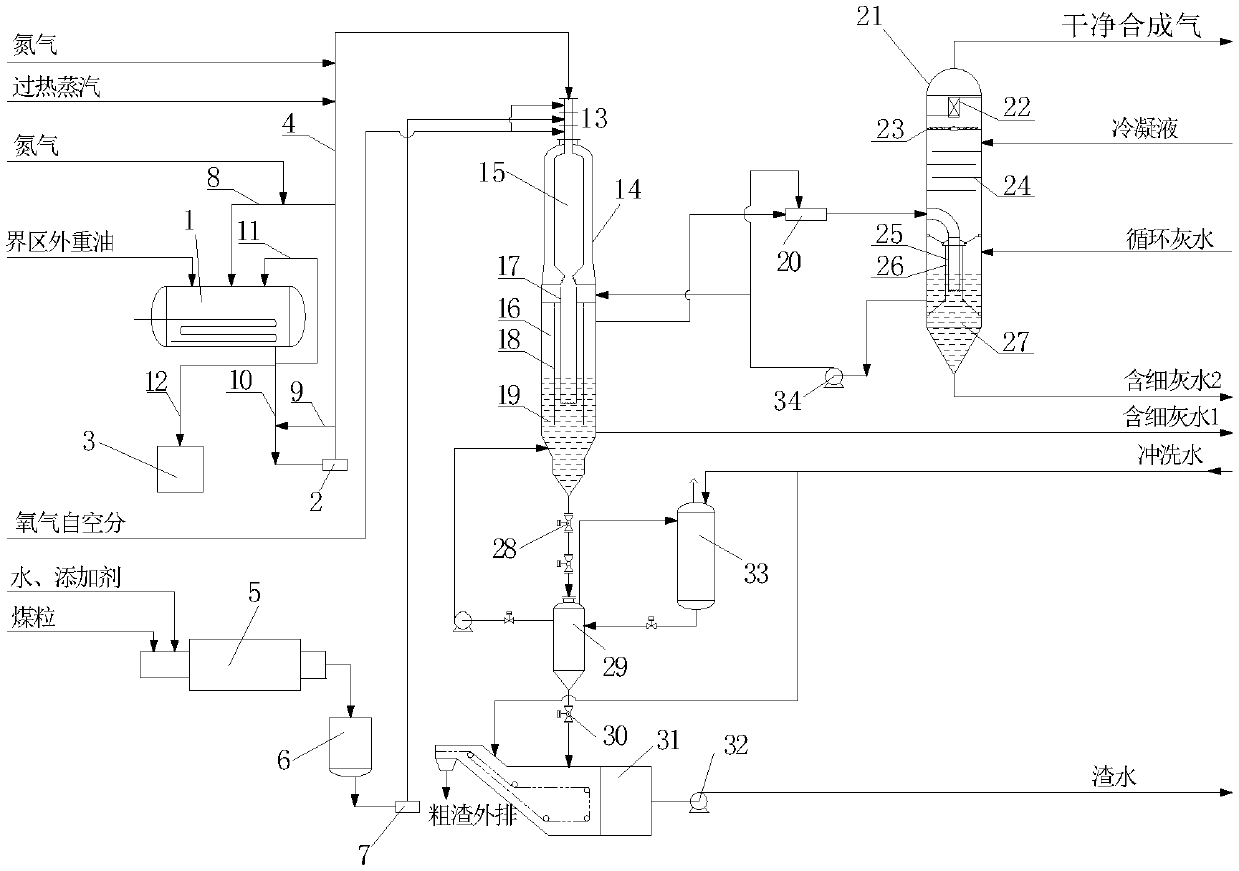

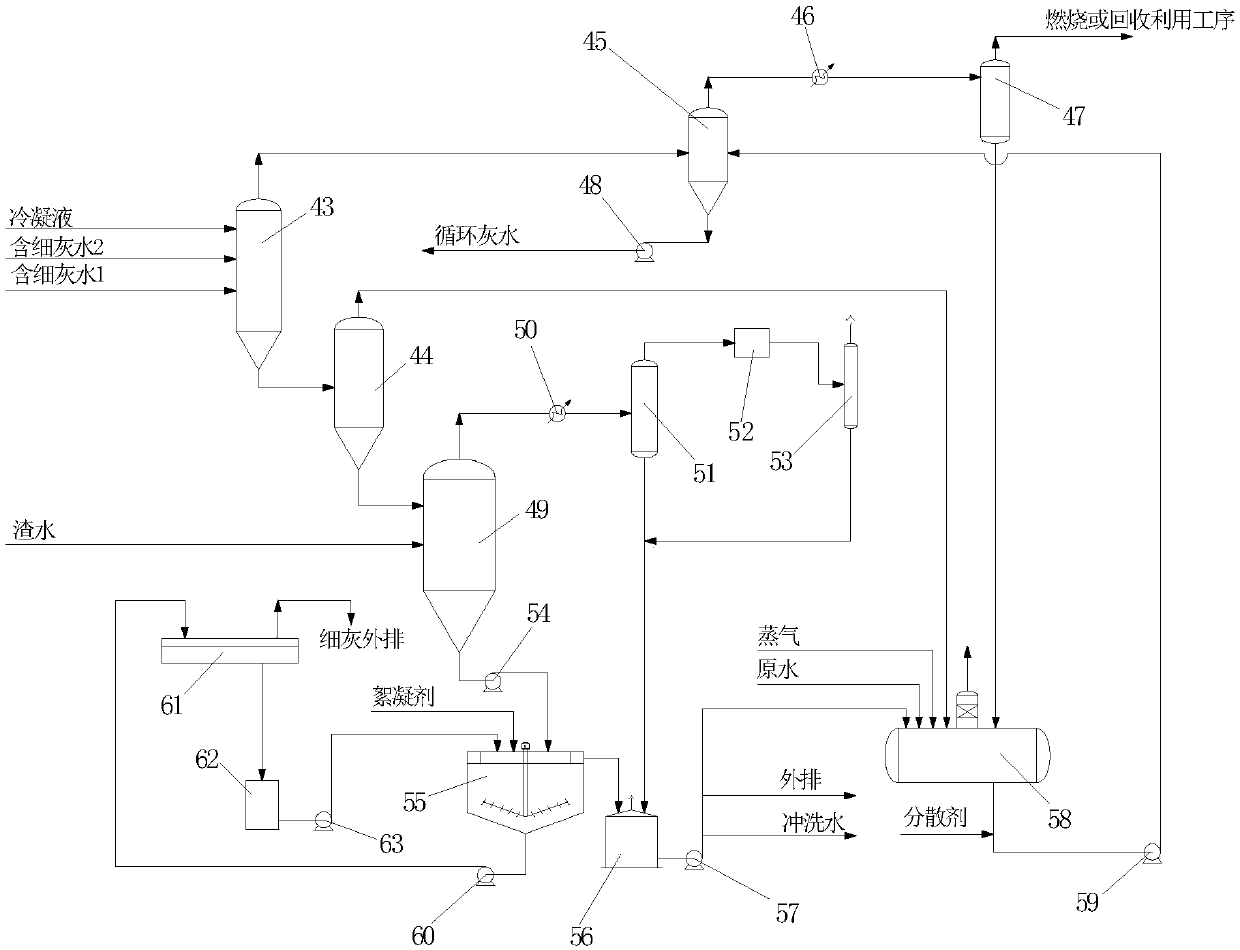

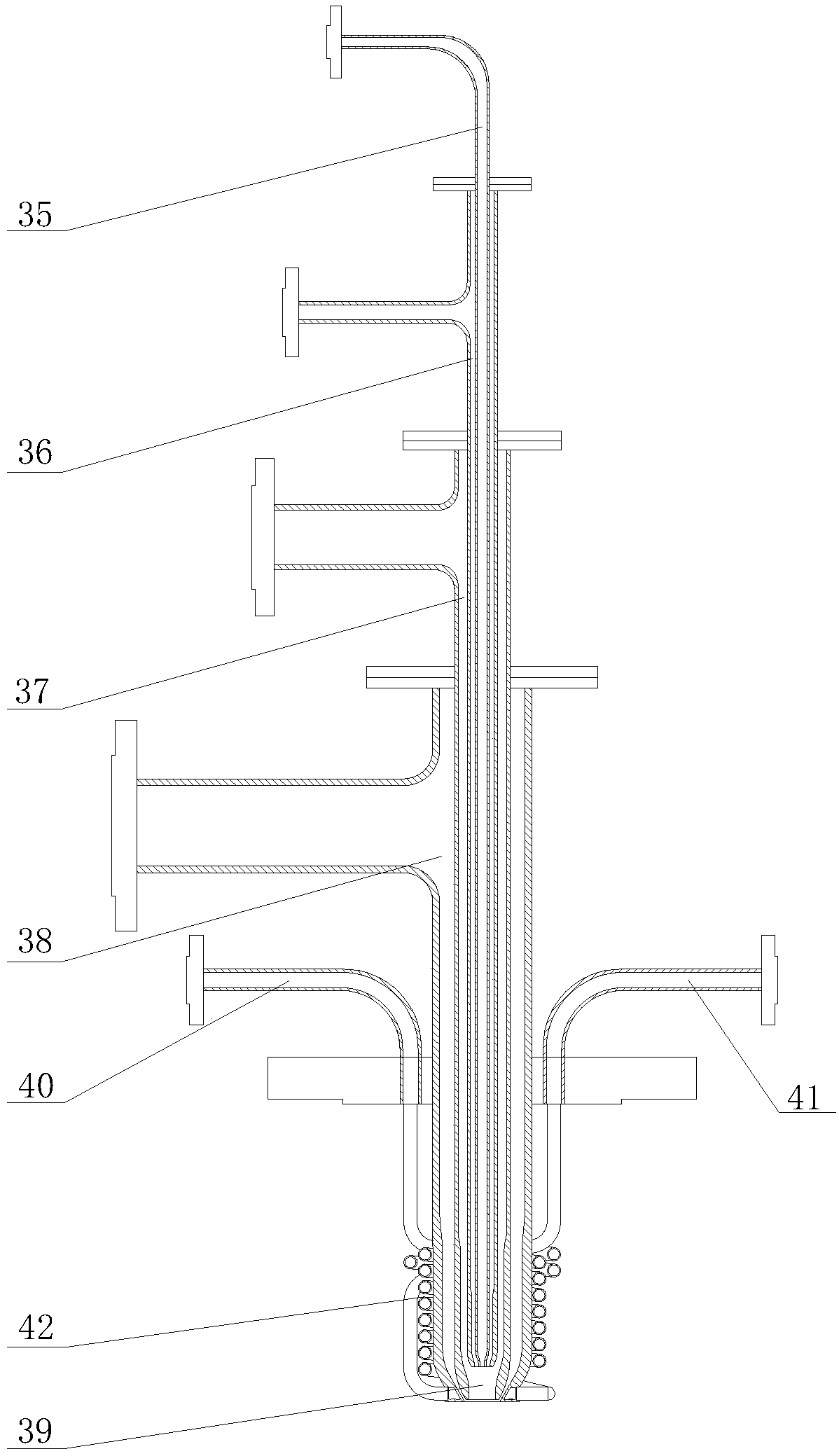

[0082] Step 1. Storage and transportation of heavy oil and preparation and transportation of coal slurry

[0083] The heavy oil from the Weiqiang coal and residual oil cracking olefins plant is sent to the heavy oil storage tank 1 for storage, and the heavy oil in the heavy oil storage tank is then pressurized to 1.5MPa by the high-pressure heavy oil pump 2, and sent to the gasifier through the heavy oil pipeline 4 The outer material channel 37 in the four-channel nozzle 13 at the top;

[0084] In this embodiment, the high-pressure heavy oil pump 2 is a piston-type diaphragm pump, such as a product sold by Shanghai Huishang Engineering Equipment Co., Ltd. under the trade name of Feluwa pumpen.

[0085] Weiqiang bituminous coal is crushed to obtain coal particles with a particle size of ≤20mm, and the coal particles, water, sodium hydroxide, and sodium lignosulfonate are respectively sent to the mill 5 for mixing and grinding to obtain coal slurry, and The coal slurry is sent ...

Embodiment 2

[0149] In this embodiment, the difference from Example 1 is that the mass percentages of coal particles, water, dispersant and pH regulator in the coal slurry are respectively: 59% of coal particles, 40.66% of water, 0.3% of dispersant, and PH Regulator 0.04%, the dispersant is calcium lignosulfonate, and the raw coal is gas coal.

[0150] In step 1, the heavy oil is pressurized to 7.0 MPa by the high-pressure heavy oil pump 2, and is sent to the central material channel 35 in the four-channel nozzle 13 on the top of the gasifier through the heavy oil pipeline 4; the coal slurry is pressurized by the high-pressure coal slurry pump 7 to 7.0 MPa is sent into the outer material channel 37 in the four-channel nozzle 13 .

[0151] In step 2, coal slurry, heavy oil and oxygen are subjected to partial oxidation reaction at a temperature of 1320° C. and a pressure of 4.0 MPa; the temperature of the heavy oil is maintained at 70° C.

[0152] In the present embodiment, further, the den...

Embodiment 3

[0157] In this embodiment, the difference from Example 1 is that the mass percentages of coal particles, water, dispersant and pH regulator in the coal slurry are respectively: 64% of coal particles, 35.5% of water, 0.45% of dispersant, and PH Regulator 0.05%, the dispersant is naphthalenesulfonic acid sodium salt formaldehyde condensate, and the raw coal is long-flame coal.

[0158] In step 1, the heavy oil is pressurized to 9.5MPa by the high-pressure heavy oil pump 2, and is sent to the central material channel 35 in the four-channel nozzle 13 on the top of the gasifier through the heavy oil pipeline 4; the coal slurry is pressurized by the high-pressure coal slurry pump 7 to 9.5 MPa is sent into the outer material channel 37 in the four-channel nozzle 13 .

[0159] In step 2, coal slurry, heavy oil and oxygen are subjected to partial oxidation reaction at a temperature of 1350° C. and a pressure of 6.5 MPa; the temperature of the heavy oil is maintained at 80° C.

[0160]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com