Composite material with sandwich structure and its preparation method and application

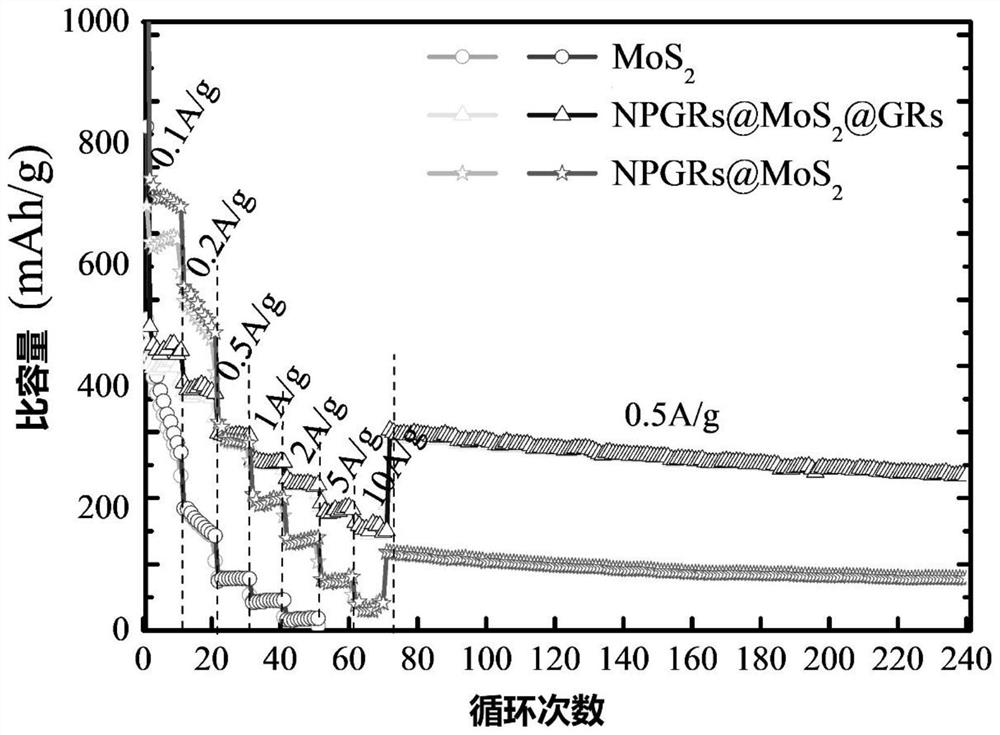

A composite material, sandwich technology, applied in structural parts, nano-carbon, graphene, etc., can solve the problems of poor cycle performance, large volume deformation, poor rate capability, etc., to expand the application range, high capacity, and good rate performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

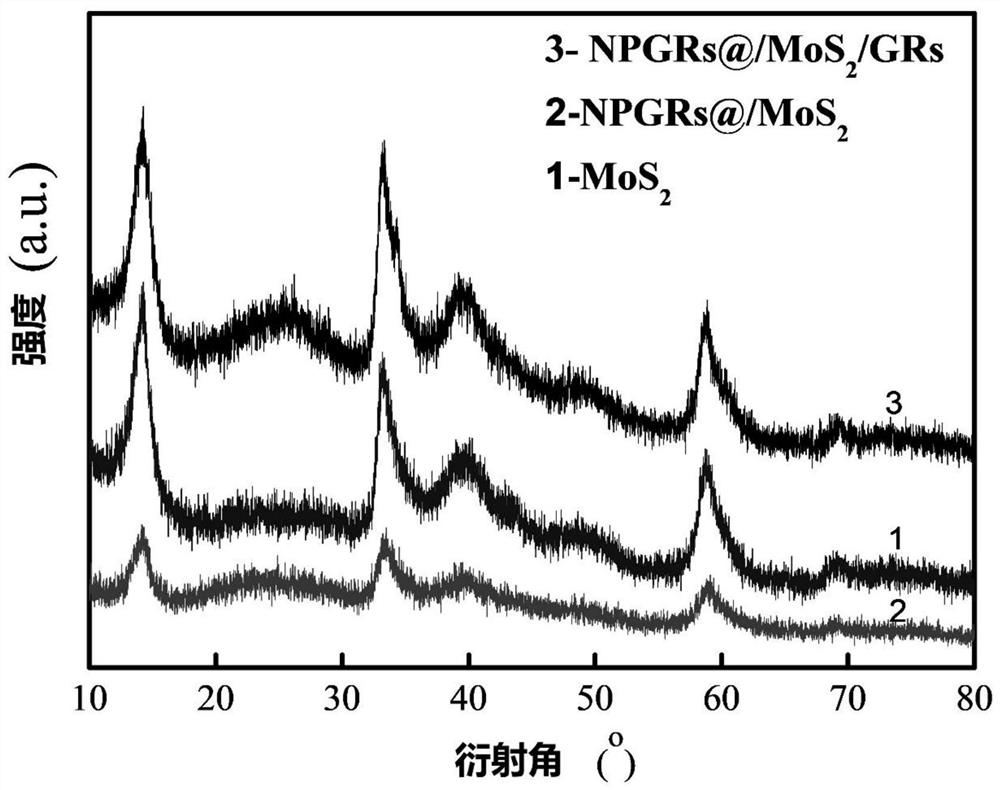

[0044] The sandwich structure graphene-molybdenum disulfide-nitrogen-doped porous graphene composite (NPGRs@MoS 2 @GRs):

[0045] The previous steps (a)-(d) are the same as those in Comparative Example 2.

[0046] (e) Preparation of sandwich-type graphene-molybdenum disulfide-nitrogen-doped porous graphene composite: take 100 mg of NPGRs@MoS from step (d) 2 Disperse in 100mL deionized water, add 2.91mg cetyltrimethylammonium bromide, stir and react for 30min, add 15mL uniformly dispersed 2mg / mL graphene oxide solution, heat up to 98°C, add 0.5mL hydrazine hydrate After reacting for 6h, the intermediate product was washed and dried. The above products were dried and put into a nitrogen tube furnace for pyrolysis. Among them, the pyrolysis process includes: rising from room temperature at 2°C / min to 420°C, keeping the temperature for 2 hours, then rising to 750°C at 5°C / min, and cooling to room temperature at 5°C / min after constant temperature for 1 hour to obtain a sandwich ...

Embodiment 2

[0051] The sandwich structure graphene-molybdenum disulfide-nitrogen-doped porous graphene composite (NPGRs@MoS 2 @GRs):

[0052] The synthesis of graphene oxide is the same as the method of comparative example 2 step (a).

[0053] (b) Preparation of polystyrene (PS): 10g styrene (St) and 0.67g polyvinylpyrrolidone (PVP) were dissolved in 160mL deionized water, then added to a reaction flask with a stirring and condensing device, and Place in an oil bath and start stirring to mix evenly, add 25mL of 20g / L 2,2'-azobisisobutylamidine hydrochloride (AIBA) solution, continue to blow nitrogen, and heat up to 75°C after 90min After reacting for 35 hours, 5 mL was taken and dried in an oven to obtain a polystyrene solution concentration of 0.0754 g / mL.

[0054] (c) Preparation of nitrogen-doped porous graphene (NPGRs): Add 2 g of PS pellets (ie, 26.5 mL of PS solution) into 500 mL of 0.2 M HCl solution and start stirring. Add 200mg of graphene oxide into 30mL of deionized water and ...

Embodiment 3

[0059] The sandwich structure graphene-molybdenum disulfide-nitrogen-doped porous graphene composite (NPGRs@MoS 2 @GRs):

[0060] The synthesis of graphene oxide is the same as the method of comparative example 2 step (a).

[0061] (b) Preparation of polystyrene (PS): 10g styrene (St) and 2g polyvinylpyrrolidone (PVP) were dissolved in 60mL deionized water, then added to a reaction flask with a stirring and condensing device, and placed side by side Put it in an oil bath and start stirring to make it evenly mixed, add 20mL 10g / L 2,2'-azobisisobutylamidine hydrochloride (AIBA) solution, continue to blow nitrogen, after 40min, raise the temperature to 65°C and react for 15h , take 5mL and place it in an oven to dry to obtain the concentration of the polystyrene solution to be 0.0754g / mL.

[0062] (c) Preparation of nitrogen-doped porous graphene (NPGRs): Add 2 g of PS pellets (ie, 26.5 mL of PS solution) into 500 mL of 0.2 M HCl solution and start stirring. Add 200mg of graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com