Preparation method and application of artificial cartilage framework

A cartilage and artificial technology, which is applied in the field of preparation of artificial cartilage scaffolds, can solve the problems that cryogenic technology cannot completely remove cell debris, decellularization technology is not thorough enough to remove, and difficult to heterogeneous immunogenicity, so as to avoid local collapse and shorten Effects of surgery time, good shape and support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In some embodiments, the preparation method of the artificial cartilage scaffold of the present invention includes steps such as pretreatment, drilling, degreasing, decellularization, antigen removal, cross-linking and fixation, and specifically includes the following steps:

[0032] a. Pretreatment: take fresh animal cartilage tissue, wash, disinfect, and remove fat tissue, fiber and fluff tissue;

[0033] b. Drilling: using mechanical or laser drilling, the hole diameter is 30-100 microns, the hole spacing is 0.5-2.0 mm, and the hole depth is 50-200 microns;

[0034] c. Degreasing: Animal tissue is extracted by supercritical carbon dioxide or organic solvent extraction to remove fat and fat-soluble impurities. The degreasing rate reaches more than 99%, and the residual fat mass ratio is 0-0.5%;

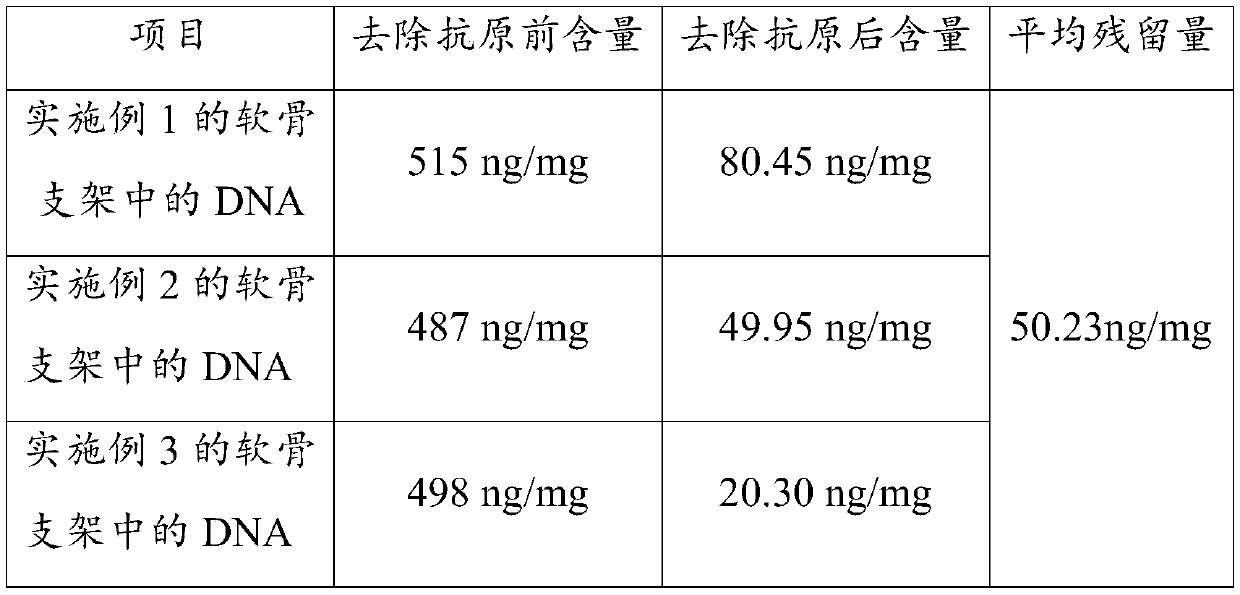

[0035] d. Decellularization: Use a surfactant solution (one or more of small molecule organic acid anhydrides, acid chlorides, amides, epoxides, and methyl halides) combined ...

Embodiment 1

[0040] A kind of embodiment of the preparation method of artificial cartilage support of the present invention, comprises the steps:

[0041]a. Pretreatment: take fresh animal cartilage tissue, wash, disinfect, and remove fat tissue, fiber and fluff tissue;

[0042] b. Drilling: using mechanical drilling, the hole diameter is 30 microns, the hole spacing is 0.5 mm, and the hole depth is 50-200 microns;

[0043] c. Degreasing: animal tissue adopts supercritical carbon dioxide extraction method to remove fat and fat-soluble impurities, the degreasing rate reaches 97%, and the residual fat mass ratio is 0.15%;

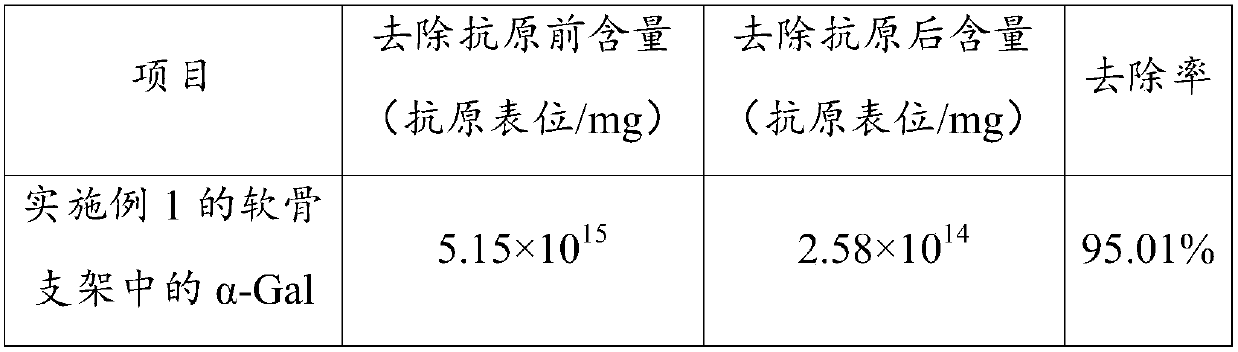

[0044] d. Decellularization: use surfactant-organic acid anhydride solution combined with protease solution, control the mass final concentration of surfactant to 0.2%, and the mass final concentration of protease to 0.25%, and carry out enzymolysis of cells in the cartilage tissue under ultrasonic conditions, Use sterile ultrapure water to clean the animal cartilage und...

Embodiment 2

[0048] A kind of embodiment of the preparation method of artificial cartilage support of the present invention, comprises the steps:

[0049] a. Pretreatment: take fresh animal cartilage tissue, wash, disinfect, and remove fat tissue, fiber and fluff tissue;

[0050] b. Drilling: using laser drilling, the hole diameter is 66 microns, the hole spacing is 1.2 mm, and the hole depth is 50-200 microns;

[0051] c. Degreasing: The animal tissue adopts organic solvent extraction method to remove fat and fat-soluble impurities. The degreasing rate reaches 99%, and the mass ratio of residual fat is 0.05%;

[0052] d. Decellularization: use a surfactant solution (a mixed solution of acid chloride and amide, wherein the mass ratio of acid chloride and amide is 1:3) and in combination with the protease solution, the mass final concentration of the control surfactant is 0.3%, the mass of the protease The final concentration is 0.2%, and the cells in the cartilage tissue are enzymolyzed u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive modulus of elasticity | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com