A kind of preparation method and application of defect-rich metal oxide

An oxide and metal technology, applied in the field of functional catalytic material preparation, can solve problems such as safety, economy and environmental protection to be improved, and achieve the effect of enriching catalytic active sites and large electronic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

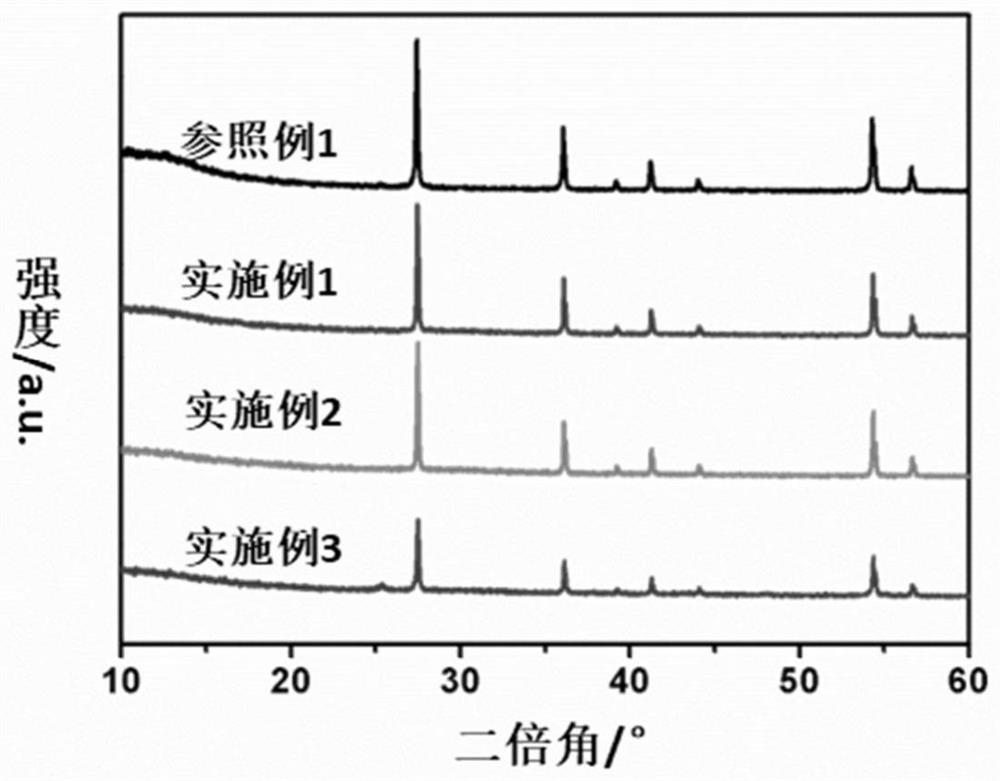

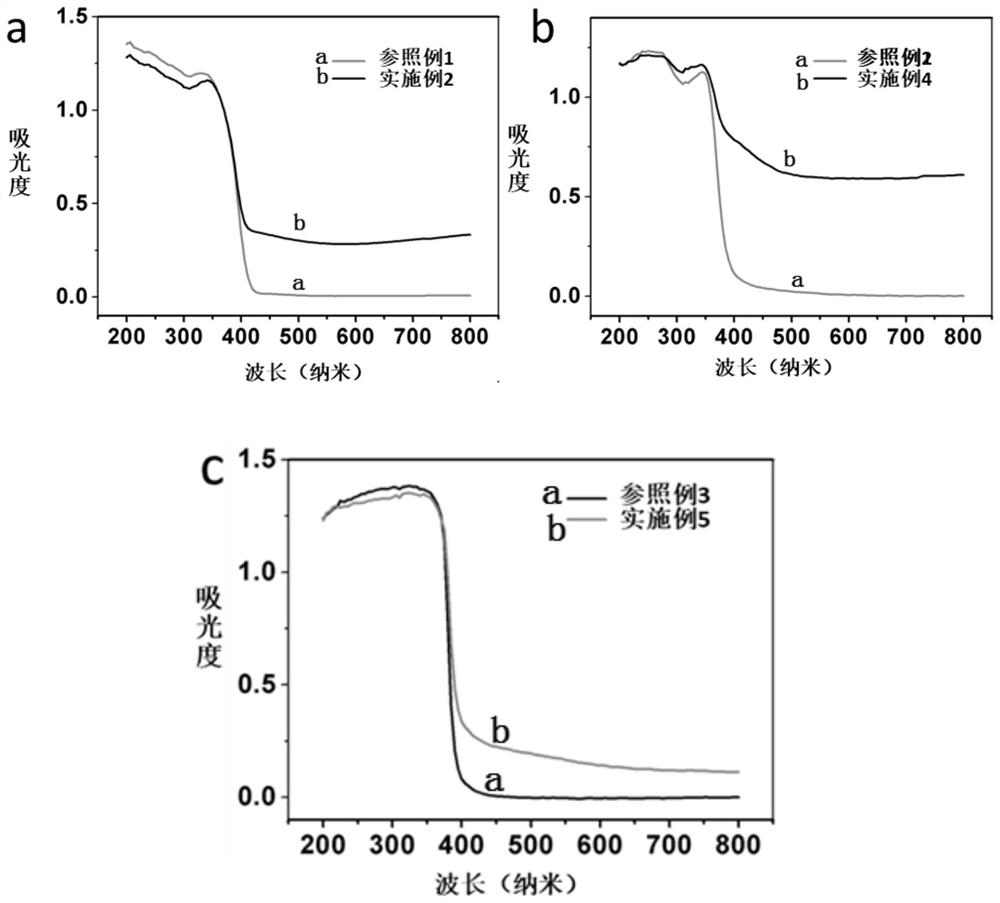

Embodiment 1

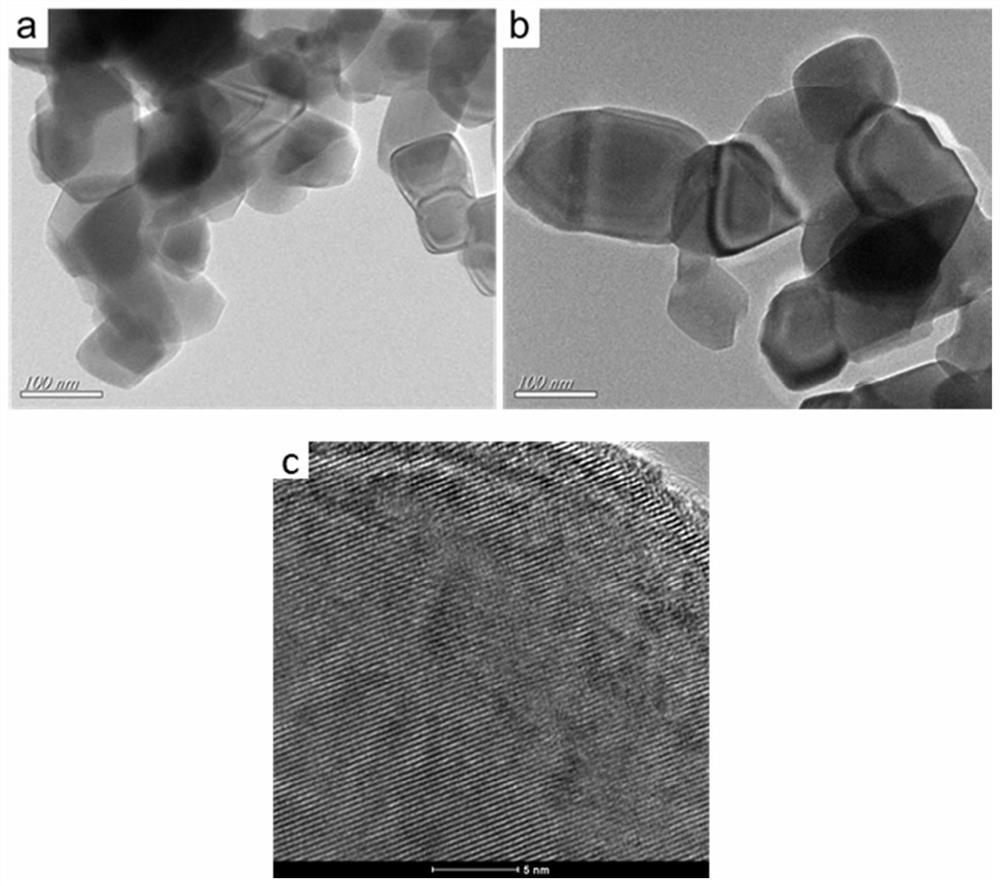

[0028] (1) Weigh urea and P25 (molar ratio 5:1) and mix them in a stainless steel ball mill tank, add zirconia balls (diameter 3mm, 20g), assemble in a planetary ball mill, set the speed at 450rpm, and the ball mill runs intermittently every 5 minutes , the intermittent time is 2.5 minutes, and the total running time is 4h.

[0029] (2) The ball-milled material is placed in a tubular electric furnace, and under the protection of nitrogen gas with a gas flow rate of 5mL / min, it is raised from room temperature to 900 °C at a rate of 5 °C / min, kept for 60 min, and cooled to room temperature. The gray matter obtained is the defect titanium dioxide material.

Embodiment 2

[0031] (1) Weigh urea and P25 (molar ratio 15:1) and mix them in a stainless steel ball mill tank, add zirconia balls (diameter 3mm, 20g), assemble them in a planetary ball mill, set the speed at 450rpm, and the ball mill runs intermittently every 5 minutes , the intermittent time is 2.5 minutes, and the total running time is 4h.

[0032] (2) The ball-milled material is placed in a tubular electric furnace, and under the protection of nitrogen gas with a gas flow rate of 5mL / min, it is raised from room temperature to 900 °C at a rate of 5 °C / min, kept for 60 min, and cooled to room temperature. The gray matter obtained is the defect titanium dioxide material.

Embodiment 3

[0034] (1) Weigh urea and P25 (molar ratio 30:1) and mix them in a stainless steel ball mill tank, add zirconia balls (diameter 3mm, 20g), assemble in a planetary ball mill, set the speed at 450rpm, and the ball mill runs intermittently every 5 minutes , the intermittent time is 2.5 minutes, and the total running time is 4h.

[0035] (2) The ball-milled material is placed in a tubular electric furnace, and under the protection of nitrogen gas with a gas flow rate of 5mL / min, it is raised from room temperature to 900 °C at a rate of 5 °C / min, kept for 60 min, and cooled to room temperature. The gray matter obtained is the defect titanium dioxide material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com